Operaling Inslructions

and Parls l.lanual

Est mate 2 CFM reduclion ln

air llow lof each loot ol duct; 15

CFM reduction for each

90'curved bend. Pneumaiic

conveyance oi wood dusl requires

a

minimum

air veloclly ol

3500

FP[4 in

lhe hose or duct; higher lor heav]er

materiats.

CFIV must not

be

reduced

below the level requlred

lo

provide

this arr velocily.

Maintenance

High voltage

electical

powet

can

cause severe iniury

or death. Always

clisconnect

of lock out ,rom

tmwer source and let motor

come to

a complete stop belore inspecting,

moving ol

lf a vibralion should

develop it may indicate excessive wear

or

damage to lhe blower wheel.

In this case, with the motor

lurned

OFF and LOCKED

OUI inspect the blower whee. lf

any damaged or excessivey worn

areas are noted, replace

A WASI{[{G

A

CAUTIOI{

Do not opercte the

alust collector

with a damagecl ot severcly wom

Do not operate with

a won or

clamaged lilEr

bag as escaping clu6t

A WARIIIiIG

A

CAUTIOI{

High spee.l

rctating equlpment can

cause severe

perconal

injury

Wear

eye

prctectlon

while using an

at hose tor

cleaning-

blower wheel. The

wheel may disinEgrcte

at opeating

speecl anr! high

speecl fragrnenls may cause

death or

sevete

perconal

injury

ancl

prcperty

clamage.

FILTER

BAG

(DO

NOT BEMOVE

WHILE UNIT IS RUNNING)

Perlodca

ly check the filler

bag

for

worn or damaged areas.

Beplace

lhe bag il worn or damaged

areas are lound.

Disconnect

of lock out trom

power

source ancl let motor

come to

a complete stop belore inspecting,

moving or

MOTOR

The

bearings on the electricalmoror

are

lubrlcaled

and seaed

for lile,

so they need no lubrication

durlng use. Keep lhe motor

clean

as excessive dul may

prevenl proper

coo

ing,

use no

more lhan

50

psi

air lo blow off excessive

dirl.

could leacl to

rcspitation

(brcathing) prouems

ancuot eye

clamage or blinclness.

It lhe inieior surlace

ol lhe bag becomes didy and

a

notceable

drop-ofl in air ilow

deveops, lhe bag may need to

be cleaned. Disconnecl molor

or lock out lrom

power

source.

Remove

ihe bag and lurn inside

oul. Use low

pressure

aif to

dislodge

sudace dusl. ll l\e

dusl ls lodged below the surface,

ihe bag may

be washed. Wa3h using

a cold wdle .

gertle

cycle,

and

ine

dry. lf the bag becomes

dirty aga n very

quickly,

anolher labric type may

be needed.

Do nol wash

fet labric filler bags which

have a sudace

coating;genlly

r nse lhe coal ng with

water

BLOWEF WHEEL AND

STEEL COMPONENTS

The cast alumrnum

blower wheeland steelcomponents are

mainlenance free and shou

d nol require any maintenance

during the ife oi the unit-

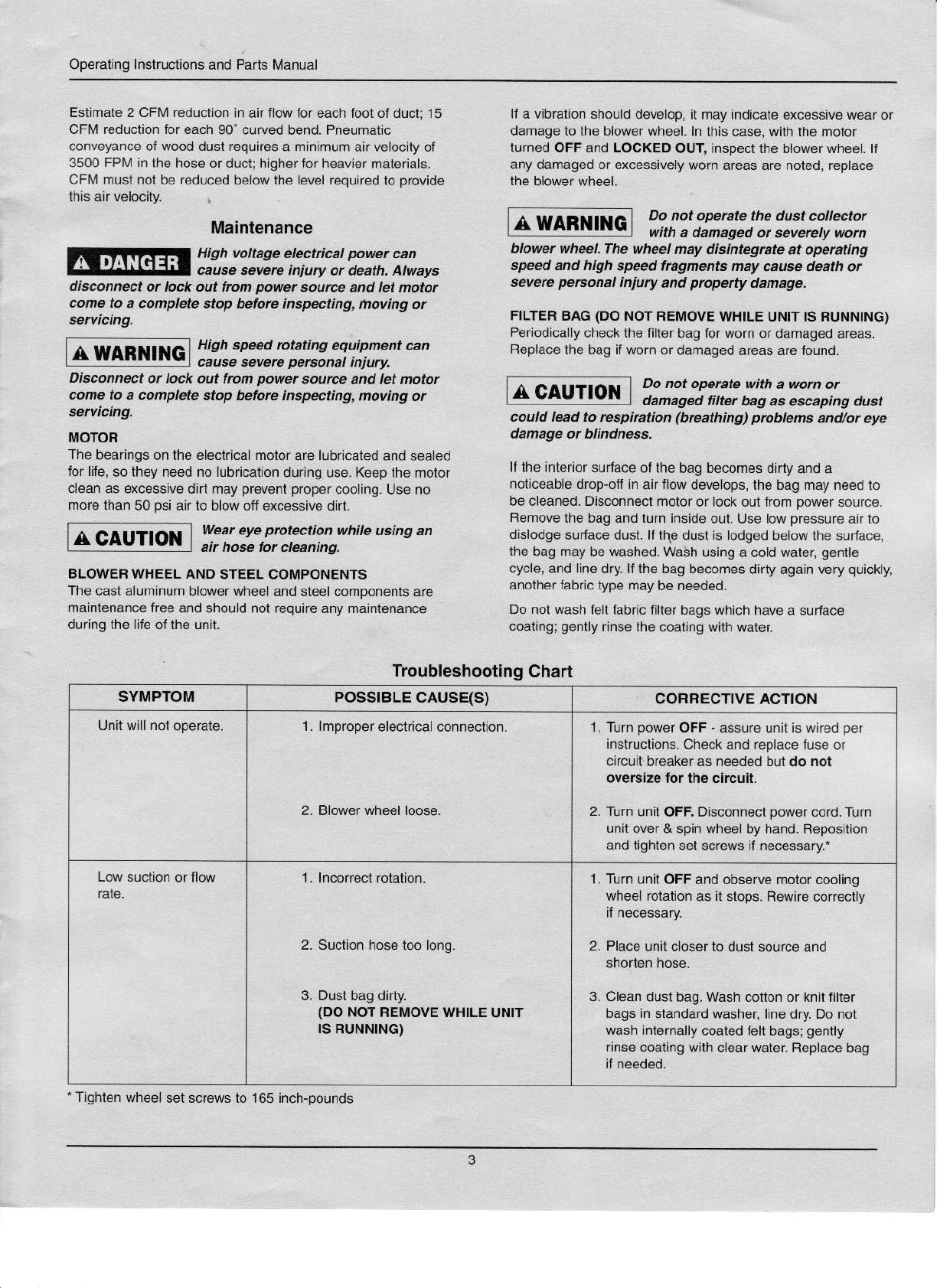

Troubleshooting

Chart

SYMPTOM

POSSIBLE CAUSE(S)

CORRECTIVE ACTION

unit w ll nol

operate. 1. {mproper

electrical connecl on.

2. Blowef wheel loose.

1.

Turn

power

OFF

-

asslrre

unil

is wired

per

instruclions. Check and replace luse

or

clrcuit breaker as needed but do not

oversize tor the circuit.

2. Turn

unil OFF. Dsconnect

power

cord.Turn

unit over

& spin wheel by hand. Beposilion

and tighlen

sel screws il necessary.'

2. Suclion hose too long.

3. Dusl bag dirty.

{DO

NOT REMOVE WHILE

UNIT

IS

RUNNING)

1.Turn unil OFF

and observe motor cooling

whee rciation as il

stops. Rewire correcly

Place

unit coser to dusl

source and

Clean

dusl bag. Wash collon or kn t filrer

bags in

slandard washer, line dry. Do not

wash nternally

coated felt bags;gently

rinse coating wlth

clear water. Replace bag

2.

3.

'Tighlen wheel

set screws to 165 inch-pounds