Exhaust Volumes Required

WOODWORKING

Equipment

Size

Min. CFM

Required

Q\

Krife Lengrh

=

Up to 6^

6+ to 12'

'

12+'

to 20'

ovet 20'

350

440

550

800

Sander, Bell

(Horizonlal)

Bell Widlh

=

Upto 6

6+' to I'

9+ ro 14

790

(3)

900

(3)

1240l3J

Sander, Disc

D sc Diameref

=

Up to 12'

12+

to iB

18+'lo 26'

350

450

550

Drum Sudace

=

Up to 200

(in

square nchet 201 to 400

401

to 700

701 lo 1400

350

550

785

1100

Blade Width

=

Up

ro

2'

2+" lo 3'

3+ lo 4'

700

(3)

s00

(3)

1350 {3)

Saw, Badial Hood

behind b ade

=

From

pod

on b ade

glard

=

Total=

430

70

500

Saw, Swing Blade

Diarneter

=

Up lo 20

over 20'

350

440

Blade Diameter

=

lJp to 16'

16+

to 24'

ovet 24

Vaieiv with

dado

=

350

440

550

550

Planer,

Single Knile Length

=

Up to 20'

20+' lo 26'

785

1100

for

Ditterent Applications

(1)

METALWORKING

Equipmenl

Size

Min, CFM

Required

{4)

Bufiing,

Belt Bell Widlh

=

Up to 3'

3+ lo5

5+ lo

7'

7+'lo 9'

9+ to

11'

11+ lo J3

220

300

390

500

610

740

Bufiing,

Wheel

3

5

6

300

500

610

740

1040

Gfindlng Wheel

\5)

1

1/2

2

3

5

6

220

220

390

500

610

880

1200

Grinding wh€el

\5)

1.1/2'

2"

,3'

5'

220

390

610

740

880

1200

(r)

(2)

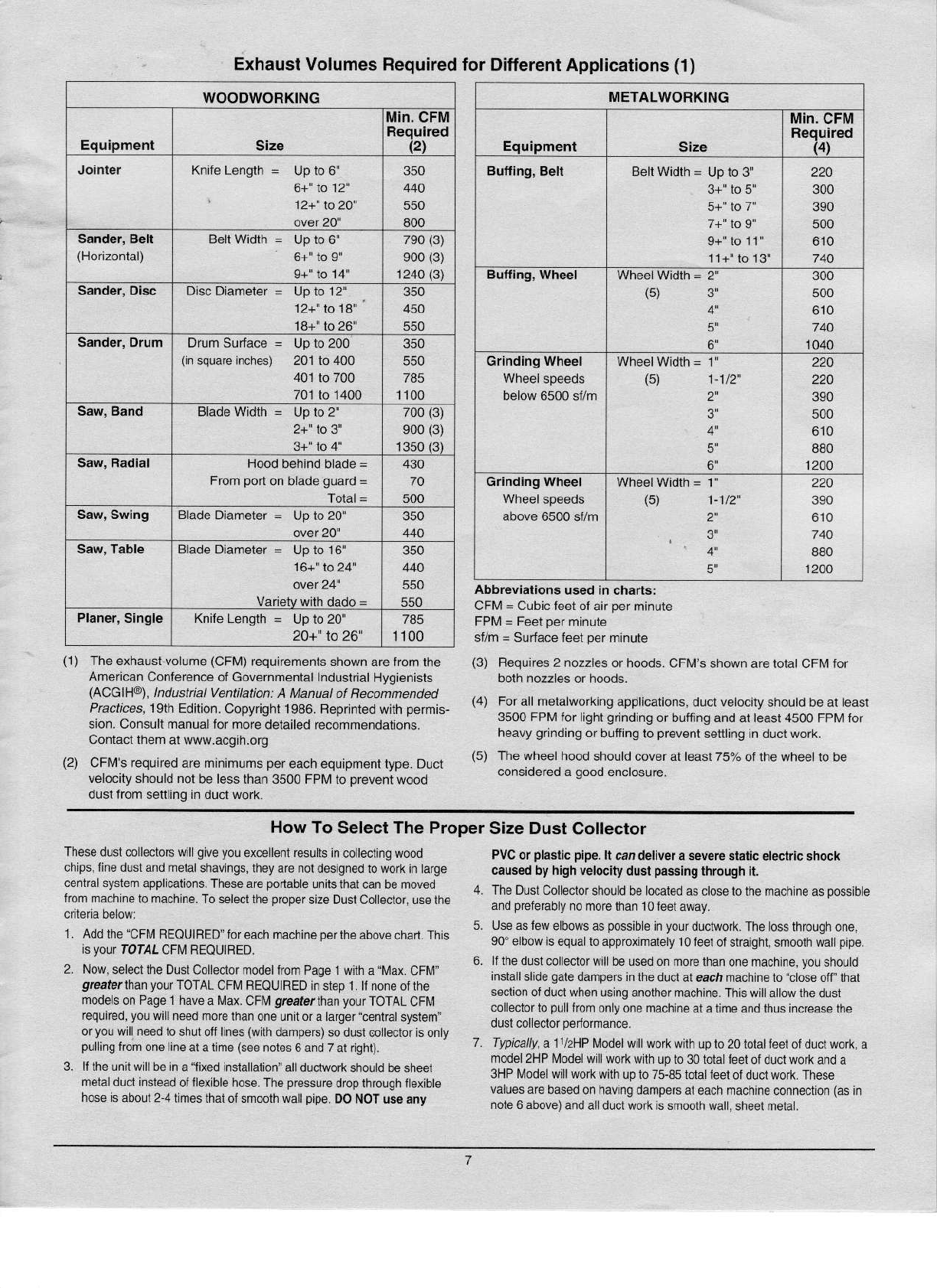

The exhausl vollme

(CFlVl)

requircmenls shown

arc

trom

the

American

Conference oi Governmentar Industriat

Hygienisls

\ACGIH@),

lntlustriai ventitation:

A Manual ot Fecannnenoeo

P.a.rbes, 1gth

Editiof. Copyighl 1986. Beprnred

wilh

permis-

sion. Consult nranua tor more

detailed recommendaiions.

Conlacl lhem

al www.acgih.org

CFMs

requlred

are mnimums

pereach

equipmenl lype. Duci

velocity should nol

be less lhan 3500 FP[,4 to

prevent

wood

dusifrom setling in ducl work

Abbreviations

used in charts:

CFI\,,|= Cubic leet ol

air

per

minute

FP[,4

=

Feet

per

minute

sflm

=

Surface leet

per

minute

(3)

Feqlires 2 nozzes

or hoods. CF[/is shown

are totatCF|M for

bolh nozzles or hoods.

(4)

For all melalworkng

applications, ducl velociiy should

be at

least

3500 FPM

for light

g

nding or b!fiing

and at least 4500 FPIVI IoT

heavy

grinding

or bltiing

lo

prevenl

seltling in dlciwork.

(5)

The wheel hood

should cover al leasl 75%

oi the wheei 10 be

considered a

good

enclosure.

How

To Select The Proper

These dusl m lectols wllgiv€

you

excellenl resrlts in

co lectirg wood

ch

ps,

Iine dust and metalshav

ngs, theyare noldesigned

to work in targe

centralsyslem

applcalions These are

portable

uritsthatcan be moved

llom machne

to machne. To selecl the

propersize

DustColleclor 6eihe

I Addth€'CFM

BEOUIBED" lor

each machineperlhe above chart. Th

s

5

s

yolr

t0,41cFlv

REourBED.

2 Now,

select the Duslcolieclor modelfrom

Page l wilh a'lvtax

cFM'

6

geater

lhan

your

TOTAL

CFM

FEOU

IRED n step 1 . ll none

or the

models

on Page t have a Max.

CFM

greaferlhan your

TOTAL

CFM

required, you

wi I need more

than one unit ora larger

'centratsyslem'

oryornl

-pFdrosh-

ofInesrw i daloe !l

\odL,rcolecro' <onlv

-

pul

iag lrom or rle

ar a ine'<,Fe nolps b d o 7

c'.qht/.

3. lllhe untwl be n

a lixed nslalalion'at duclworkshoutd

be sheel

metalducl ifsiead

olliexble hose. The

pressure

drop thmugh i exible

hose is aboirl 2

4 I mes lhai of smmlh wa I

pipe

DO NOT use any

Size Dust

Collector

PVC or

plaslic pipe.lt

ca, deliver a severe st.tic

etectric shock

caused by high velocity

dust

passlnglhrcugh

it.

The Dusl

Colreclorsholld be localed ascloselothe machne

aspossible

and

preieraby

fo more lhan 10leel away

Use as iew

erbows as

possible

in

yowducnrofi.

The loss through one

90'ebow

sequallo approxmalery l0ieetotstraighl,

smoollr wat

pipe.

llthedusl

col€clorwil be used on morelhan

one machne,

you

sholld

insla I

sl de

gale

danrpe6 in lhe

ducr at eac, mach ne 10

"close

ofl' lhal

seclion

ol ducl when us ng anolher machire.

This wl allow lhe d!s1

colleclorto

pu

I ffom on

y

one machine

at a time and lhus increase the

dusl col eclor

perlormance.

Iyptal/y

a 1

r/rHP

Model w I work

w th up lo 20 lolat leel ol dLcl work

a

model2HP Modelwl workwlh

uplo30tota leel

ol duct

work

and a

3HP Mode willwor*

with up to 75-85 totat leet

ot ducl wod( These

valuesare

basedon havingdampersat

each machine connection

(as

if

'ro1e

6 above)

and a Iducl work is smooth wal,

sheet meta