4

Operation (Continued)

• Exhaust Tube - This tube carries

compressed air from the pump to the

check valve. This tube becomes very

hot during use. To avoid the risk of

severe burns, never touch the

exhaust tube.

• Check Valve - A one-way valve that

allows air to enter the tank, but

prevents air in the tank from flowing

back into the compressor pump.

• Handle - Designed to move the

compressor.

• Drain Valve - This valve is located

on the bottom of the tank. Use this

valve to drain moisture from the

tank daily to reduce the risk of

corrosion.

Reduce tank pressure below 10 psi,

then drain moisture from tank daily to

avoid tank corrosion. Drain moisture

from tank by opening the drain valve

located underneath the tank.

BEFORE EACH START-UP

OPERATING PROCEDURE

1. Turn regulator knob fully counter

clockwise (to the left) to close air

flow.

2. Connect air hose to outlet of

regulator.

3. Turn on/off switch to OFF position.

4. Plug in power cord.

5. Turn on/off switch to AUTO position

and let compressor run until it

reaches automatic shutoff pressure.

6. Attach tire chuck or tool to end of

hose.

7. Turn regulator knob clockwise (to

the right) to desired pressure of tool

being used.

On/Off cycling of compressor

In the AUTO position, the compressor

pumps air into the tank. When a shut-

off (preset “cut-out”) pressure is

reached, the compressor automatically

shuts off.

If the compressor is left in the AUTO

position and air is depleted from the

tank by use of a tire chuck, tool, etc., the

compressor will restart automatically at

its preset “cut-in” pressure. When a tool

is being used continuously, the

compressor will cycle on and off

automatically.

In the OFF position, the pressure switch

cannot function and the compressor

will not operate. Make sure switch is in

OFF position when connecting or

disconnecting power cord from

electrical outlet.

CONNECTING / DISCONNECTING

PORTABLE COMPRESSOR

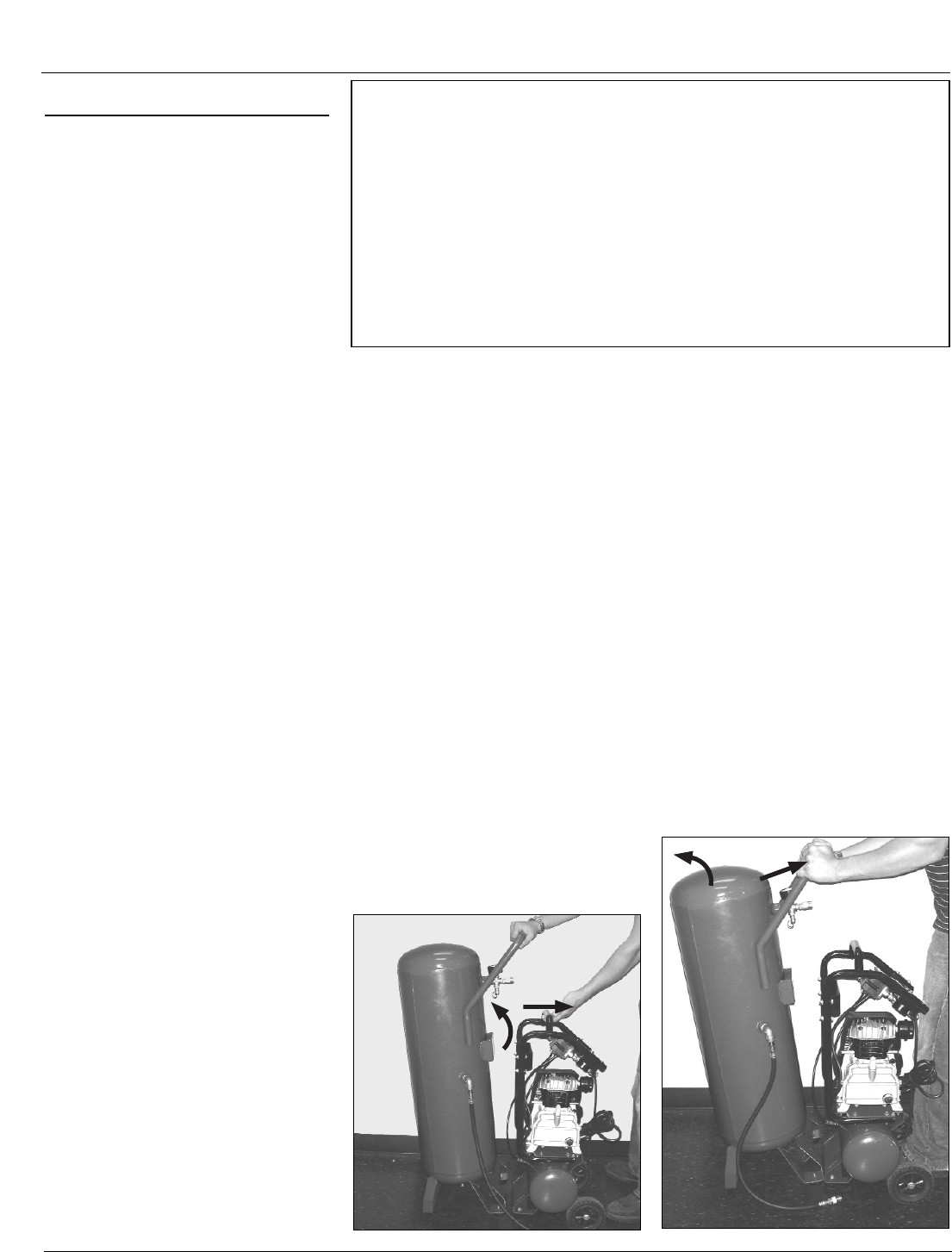

Unhooking the Small Tank from

the Large Tank

1. Remove the connection hose by

pulling back the collar on the

coupler (this is not a normal

pneumatic coupler, no air will be

discharged from the coupler or the

fitting).

2. Unscrew the knob

3. Lean back the Large Tank and pull

the Small Tank forward to unhook

the bottom of the two tanks (See

Figure 6).

4. Replace knob into large tank for

storage.

Connecting the Small Tank to the

Large Tank

1. Align the feet of the two tanks so

that the Small Tank foot bracket fits

into the Large Tank’s foot bracket

opening.

2. Lean back and slide forward the

Large Tank so that the mounting

pins on the Large Tank engage into

the holes on the Small Tank (See

Figure 7).

3. Reconnect the knob to secure the

Large Tank with the handle of the

Small Tank.

4. Reconnect the connection hose.

Note: If air pressure is in either tank it

may be difficult to push coupler onto

the fitting.

MOISTURE IN COMPRESSED AIR

Moisture in compressed air will form into droplets as it comes from an air

compressor pump. When humidity is high or when a compressor is in

continuous use for an extended period of time, this moisture will collect in

the tank. When using a paint spray or sandblast gun, this water will be

carried from the tank through the hose, and out of the gun as droplets

mixed with the spray material.

IMPORTANT: This condensation will cause water spots in a paint job,

especially when spraying other than water based paints. If sandblasting, it

will cause the sand to cake and clog the gun, rendering it ineffective. A filter

in the air line (MP3105), located as near to the gun as possible, will help

eliminate this moisture.

www.chpower.com

Oil-Lubricated Compressors

Figure 6

Figure 7