3

HX5100, HX5101

www.chpower.com

Assembly (Continued)

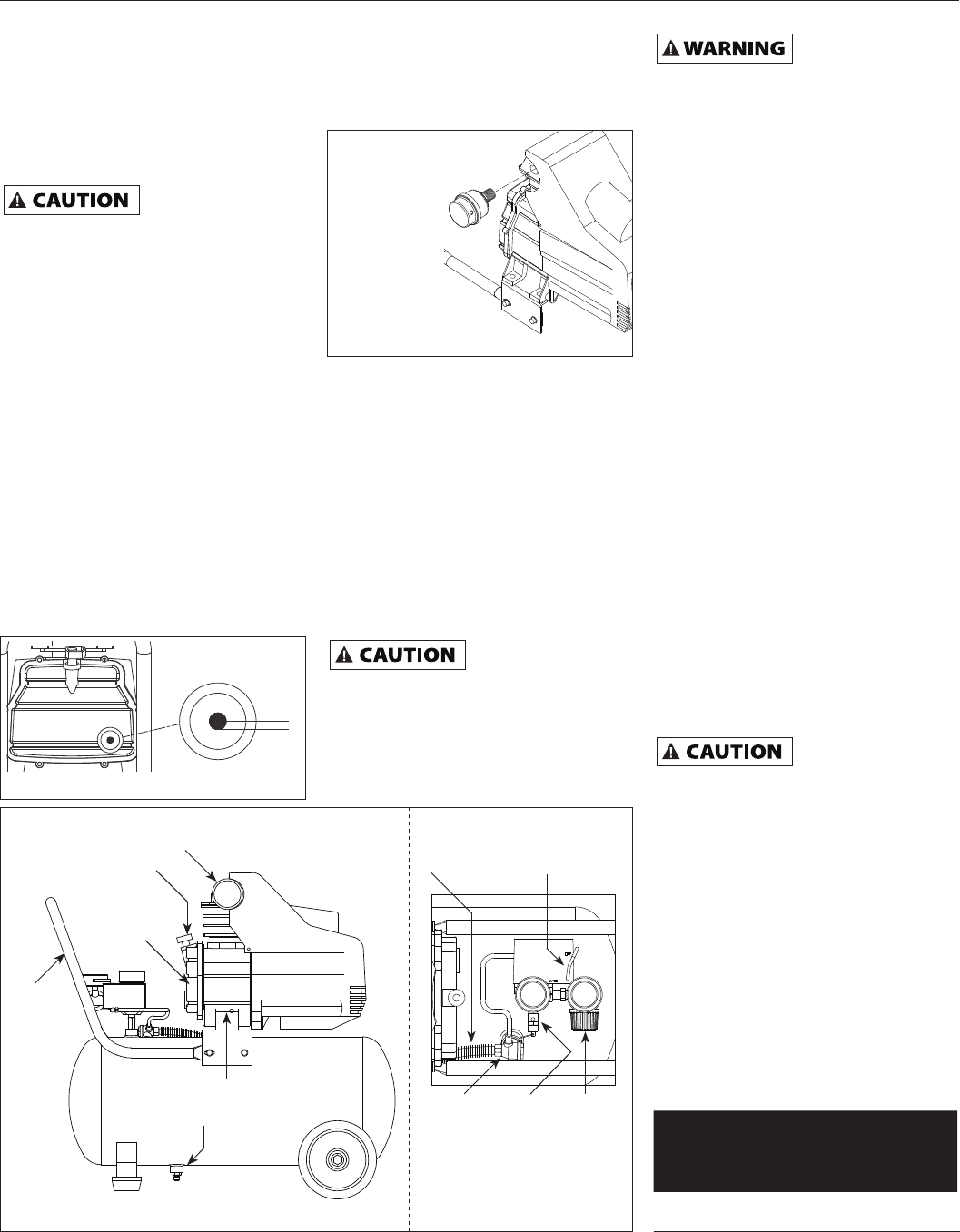

INTAKE FILTER

Thread the intake air filter into the

threaded opening in the side of the

compressor head as illustrated in Figure

4. Tighten gently with a wrench.

Figure 4 - Intake filter installation

Installation

LOCATION

It is extremely important to install the

compressor in a clean, well ventilated

area where the surrounding air

temperature will not be more than

100°F.

A minimum clearance of 18 inches

between the compressor and a wall is

required because objects could obstruct

air flow.

Do not locate the

compressor air inlet

near steam, paint spray, sandblast areas

or any other source of contamination.

This debris will damage the motor.

ELECTRICAL INSTALLATION

All wiring and

electrical

connections should be performed by a

qualified electrician. Installation must

be in accordance with local codes and

national electrical codes.

WIRING

1. Local electrical wiring codes differ

from area to area. Source wiring,

plug and protector must be rated for

at least the amperage and voltage

indicated on motor nameplate, and

meet all electrical codes for this

minimum.

2. Use a slow blow fuse or a circuit

breaker.

3. Make sure the product is connected

to an outlet having the same

configuration as the plug. This

product must be grounded. In the

event of an electrical short circuit,

grounding reduces risk of electrical

shock by providing an escape wire

for electric current. This product

is equipped with a cord having a

grounding wire with an appropriate

grounding plug. Plug must be

plugged into an outlet that is

properly installed and grounded in

accordance with all local codes and

ordinances.

Overheating, short

circuiting and fire

damage will result from inadequate

wiring.

2. Place lock washer on axle bolt. Then

tighten nut securely to threaded

part of axle bolt.

3. Repeat procedure with other side.

LUBRICATION

THIS UNIT IS

SHIPPED WITHOUT

OIL IN PUMP! Follow lubrication

instructions before operating

compressor.

Use oil shipped with the compressor. Do

not use regular automotive oil such

as 10W-30. Additives in regular motor

oil can cause valve deposits and reduce

pump life. For maximum pump life,

drain and replace oil after the first few

hours of run time.

The compressor pump takes

approximately 280 ml (9.5 ozs.) of oil.

The sight glass, located on the crankcase

portion of the pump, is marked

with “max” and “min” levels. Avoid

overfilling by adding oil gradually and

checking the oil level with the sight

glass several times. Add enough oil to

reach the “max” level on the sight glass.

Proper oil level is illustrated in Figure 3.

Figure 3 - Proper oil level

Max.

Min.

Figure 6 - Unit Identification

Intake filter

Oil fill / breather

Sight

glass

Handle

Oil drain plug

Drain valve

Check

Valve

Safety

Valve

Regulator

Exhaust

Tube

Pressure Switch

(Auto/Off)

Side view of unit

Top view of unit

Extension cords

Length of Cord (ft) 25 50 100

Gauge of Cord 14 12 10