Metal Heat

Thickness Setting

5

Model WF2010

If heating, welding, or

cutting materials that are

galvanized, zinc plated,

lead, or cadmium plated

refer to the General Safety Information

Section for instructions. Extremely

toxic fumes are created when these

metals are heated.

4. Connect the work clamp to the

work piece or workbench (if metal).

Make sure the contact is secure.

Avoid surfaces with paint, varnish,

corrosion, or non-metallic materials.

5. Position the Heat Selector on the

front panel to the desired setting.

NOTE: These settings are general

guidelines only. Heat setting may vary

according to welding conditions and

materials.

6. Rotate the Wire Speed Control to

setting number 5 to start with, then

adjust as needed after test weld.

7. Plug the input cord into a proper

voltage receptacle with proper

circuit capacity. (See Chart under

circuit requirements on page 1).

8. Switch the welder ON/OFF switch to

the ON position.

9. Verify that the wire is extended

1/4” from the contact tip. If not,

squeeze the trigger to feed

additional wire, release the trigger,

and cut wire to proper length.

10. Position the wire feed gun near the

work piece, lower the welding

helmet by nodding the head, or

position the hand shield, and

squeeze the gun trigger. Adjust heat

setting and wire speed as needed.

11. When finished welding, turn welder

off and store properly.

!

WARNING

Disconnect power

supply and turn

machine off before inspecting or

servicing any components. Keep the wire

compartment cover closed at all times

unless the wire needs replacement.

Before every use:

1. Check condition of weld cables and

immediately repair or replace any

cables with damaged insulation.

2. Check condition of power cord and

immediately repair or replace any

cord if damaged.

3. Inspect the condition of the gun tip

and nozzle. Remove any weld slag.

Replace gun tip or nozzle if

damaged.

Do not operate this

welding machine

with cracked or missing insulation on

welding cables, wire feed gun, or

power cord.

Every 3 months:

1. Replace any unreadable safety

labels on the welder.

2. Use compressed air to blow all dust

and lint from the ventilation

openings.

3. Clean the wire groove on the drive

roll. Remove wire from the feed

mechanism, remove screws from

the drive roll housing. Use a small

wire brush to clean the drive roll.

Replace if worn or damaged.

Consumable and Wear Parts

The following parts require routine

maintenance:

• Wire feed drive roller

• Gun liner - replace if worn

• Nozzle/contact tips

• Wire - This welder will accept either

4” or 8” diameter spools. Flux-cored

welding wire is susceptible to moisture

and oxidizes over time, so it is

important to select a spool size that

will be used within approximately 6

months. Use AWS type AWS E71T-GS

or E71T-11, .030" (.8mm) or .035"

(.9mm) diameter.

Call (800) 746-5641

for replacement parts

!

WARNING

!

WARNING

Operation

(Con’t)

14-20 Gauge Low

Thicker than 14 Gauge High

Maintenance

Welding Guidelines

General

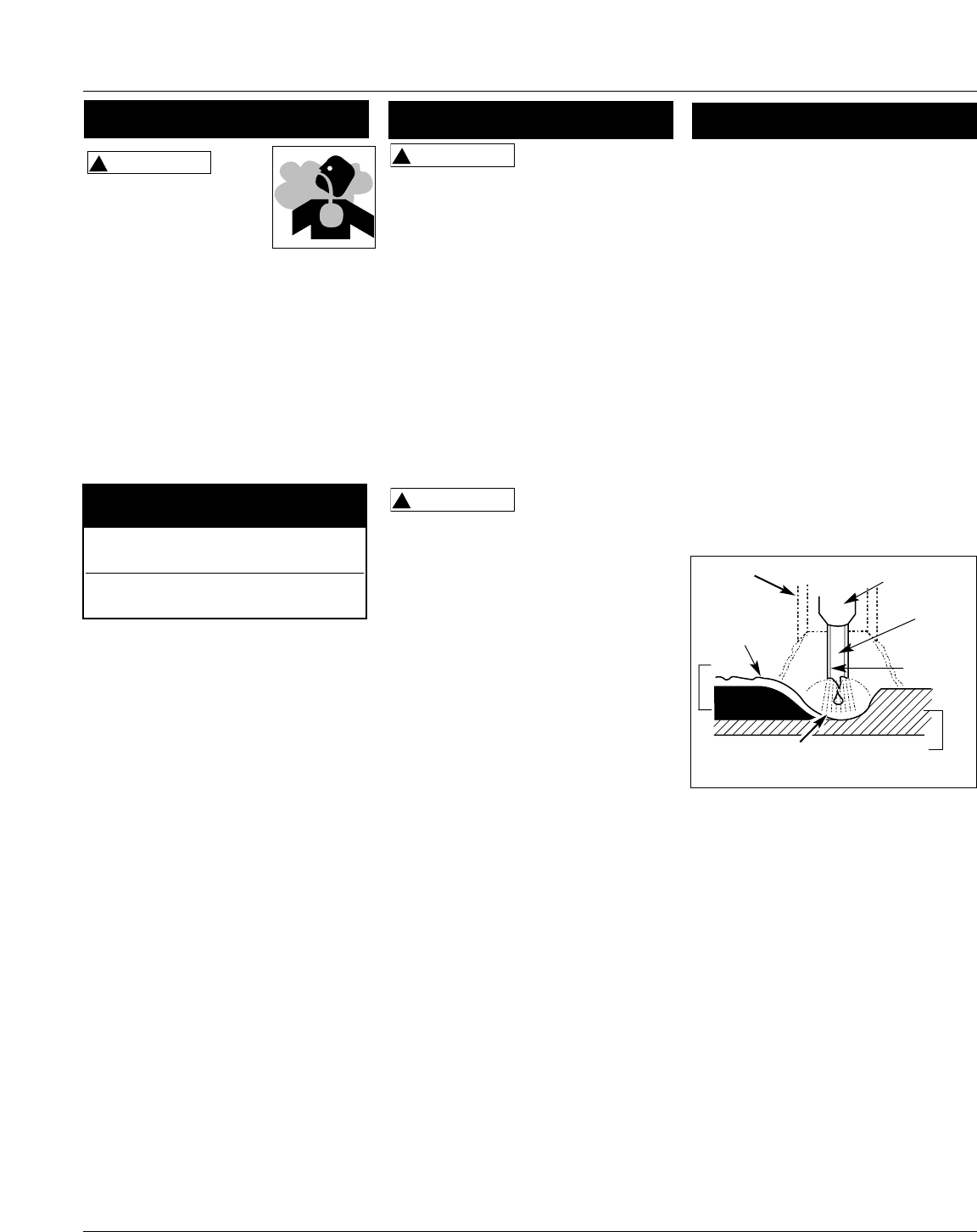

This line of welding machines utilizes

the Flux Cored Arc Welding (Gasless)

process. The weld must be protected

(shielded) from contaminates in the air

while it is molten. The gasless process

uses a tubular wire with a flux material

inside. The flux creates a shielding gas

when melted.

When current is produced by a

transformer (welding machine) and

flows through the circuit to the weld

wire, an arc is formed between the end

of the weld wire and the work piece.

This arc melts the wire and the work

piece. The melted metal of the weld

wire flows into the molten crater and

forms a bond with the work piece as

shown (Figure 7).

Arc Welding Basics

Five basic techniques affect weld

quality. These are: wire selection, heat

setting, weld angle, wire speed, and

travel speed. An understanding of

these techniques is necessary for

effective welds.

HEAT SETTING

The correct heat involves the

adjustment of the welding machine to

the required setting. The heat setting

used depends on the thickness of the

work piece. Consult specifications listed

on the welder. It is suggested that the

welder practice with scrap metal to

adjust settings, and compare welds

with Figure 12.

Slag

Weld

Wire

Flux

Work Piece

Contact

Tip

Crater

Nozzle

Figure 7 - Weld Components

www.chpower.com