8

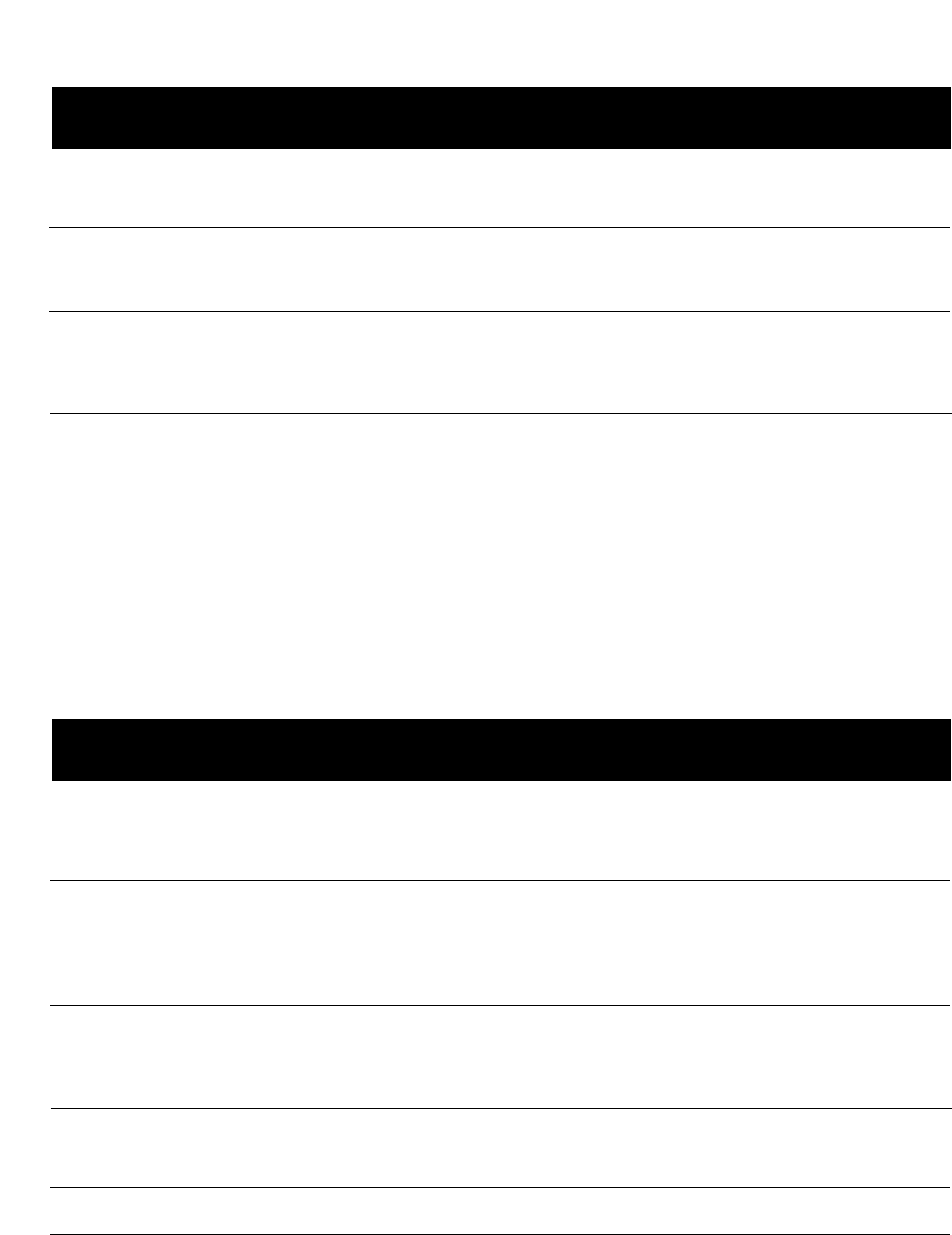

Troubleshooting Chart - Welder

Symptom Possible Cause(s) Corrective Action

1. No power at receptacle

2. Broken or damaged power

cable

1. Inadequate current at

electrode

2. Poor connections at welder

1. Accidental contact with work

piece

2. Current leakage caused by

moist clothing or work area

1. Use of extension cord

2. Electrode diameter too large

3. Overloaded circuit

1. Wrong type of electrode

2. Electrode diameter too large

3. Work piece not properly

grounded

4. Heavy loads making power

line voltage low

For Information About This Product, Call 1-800-746-5641

Bead is intermittently too

thin or too thick

Ragged depressions at

edge of weld

Weld bead does not

penetrate workpiece

Electrode sticks to work

piece

Electrodes sputter and stick

1. Inconsistent travel speed

2. Output amp setting incorrect

1. Travel speed too fast

2. Arc length too short

3. Output amp setting too high

1. Inconsistent travel speed

2. Output amp setting too low

3. Electrode diameter too large

1. Arc length short

2. Amp setting low

Damp electrodes

1. Check circuit fuse or circuit breaker

2. Power cable requires service

1. Check work clamp, cable and connection to work piece.

Check electrode cable and clamp

2. Check all welder external connections

1. Avoid contact with work piece

2. Make sure clothing and work area are dry

1. If possible, relocated welder to avoid use of extension

cord. If relocation of welder is not possible, use thicker

(lower gauge number) extension cord

2. Use smaller diameter electrode

3. Welder requires a dedicated 115V circuit

1. Verify that electrode is for alternating current (AC) use

2. Use smaller diameter electrode

3. Verify proper grounding. (No paint, varnish or corrosion)

4. Run welder on dedicated 115V circuit

Welder does not hum

when turned on

Welder hums but does not

weld

Welder gives trickle shocks

Welder overheats - blows

fuses, trips circuit breaker

Arc difficult to strike

Troubleshooting Chart - Welds

Symptom Possible Cause(s) Corrective Action

1. Carefully watch and control the width of the molten

weld bead

2. Adjust output amp setting or change to smaller diameter

electrode

1. Watch orange molten weld puddle and control bead

width

2. Practice running electrode across workpiece with welder

OFF

3. Reduce output amp setting

1. Decrease and maintain constant travel speed

2. Increase output amp setting or change to smaller

diameter electrode

3. Recommend either 1/16 or 5/64 diameter

1. Lift electrode to correct arc length as soon as arc is struck

2. Increase amp setting or change to smaller diameter

electrode

Use dry electrodes and store in dry location