A-3

INSTALLATION

INVERTER ARC™ 120

A-3

OUTPUT CONNECTIONS

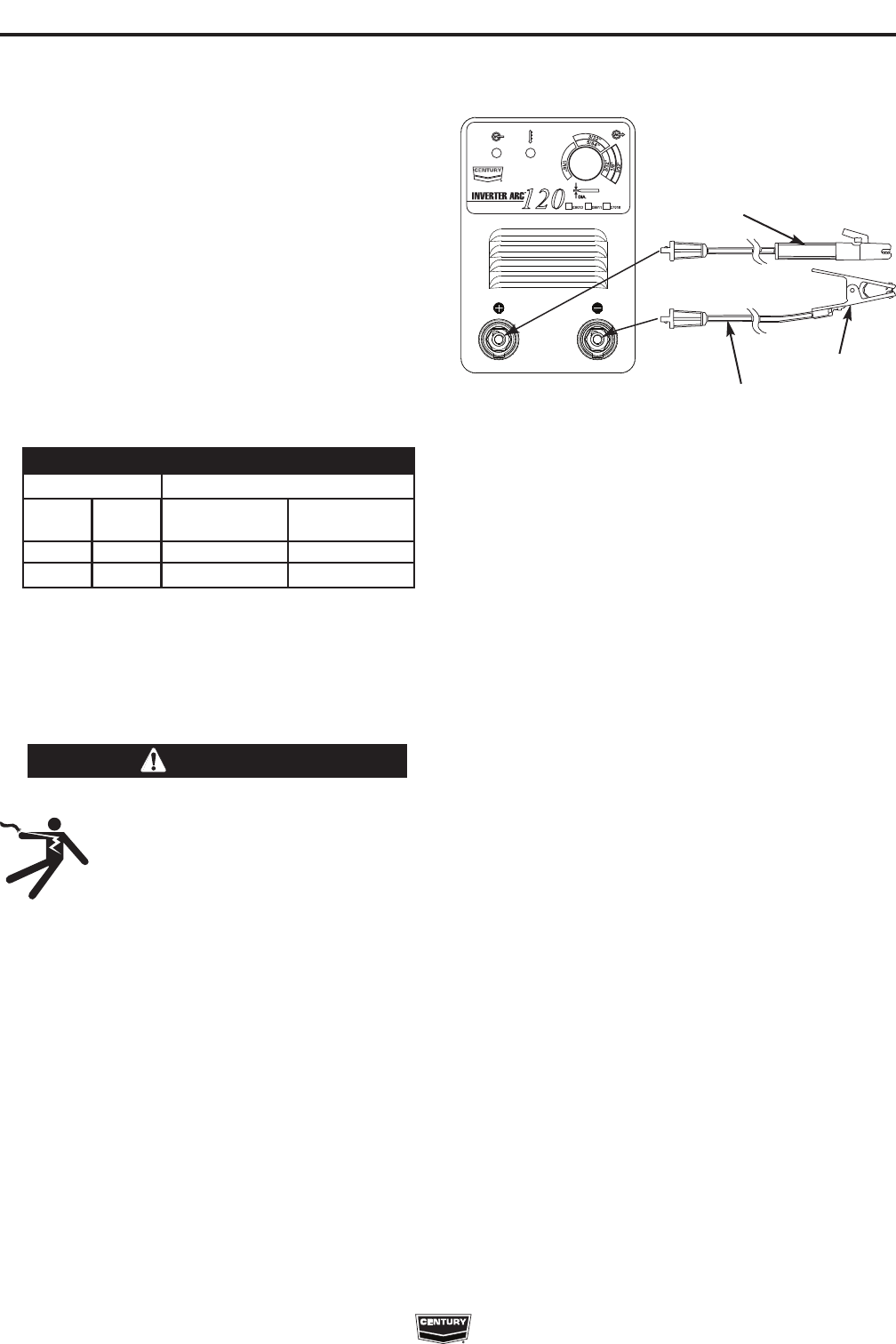

A quick disconnect system using Twist-Mate™ cable

plugs is used for the welding cable connections.

ELECTRIC SHOCK can kill.

• Keep the electrode holder and cable

insulation in good condition.

• Do not touch electrically live parts or

electrode with skin or wet clothing.

• Insulate yourself from work and ground.

• Turn the input line Switch on the INVERTER

ARC™ 120 “off” before connecting or discon-

necting output cables or other equipment.

------------------------------------------------------------

STICK WELDING (MMA)

Connect the electrode cable to the (+) terminal and the

work clamp to the (-) terminal. Insert the connector with

the key lining up with the keyway and rotate approxi-

mately 1/4 turn clockwise. Do not over tighten.

(See Figure A.1)

Work Clamp

Work Cable

Electrode

Holder

FIGURE A.1

WARNING

120V INPUT

The INVERTER ARC™ 120 is provided with a 120V

cable, 6.0ft.(1.8m) in length, with a 15Amp 5-15P plug

molded onto the cord.

The rated output of the INVERTER ARC™ 120 is

available when connected to a 20A branch circuit.

When connected to a branch circuit with lower ampac-

ity, lower welding current and duty cycle must be

used. An output guide is provided below. The values

are approximate and must be adjusted downward if

the fuse or circuit breaker trips off. Other loads on the

circuit and fuse/circuit breaker characteristics will

affect the available output. Do not exceed these weld-

ing conditions: (See Table A.1)

BRANCH CIRCUITS

Plug

Rating

15 Amp

15 Amp

Branch

Rating

15 Amp

20 Amp

20% Duty

Cycle

55A

70A

120V Input

Output Current

TABLE A.1

10% Duty

Cycle

60A

80A

Factory Installed

Electrical Holder and Cable Assembly

Work Cable and Clamp

Strap Packet

Instruction Manual