Page 14 For technical questions, please call 1-800-444-3353. SKU 68887

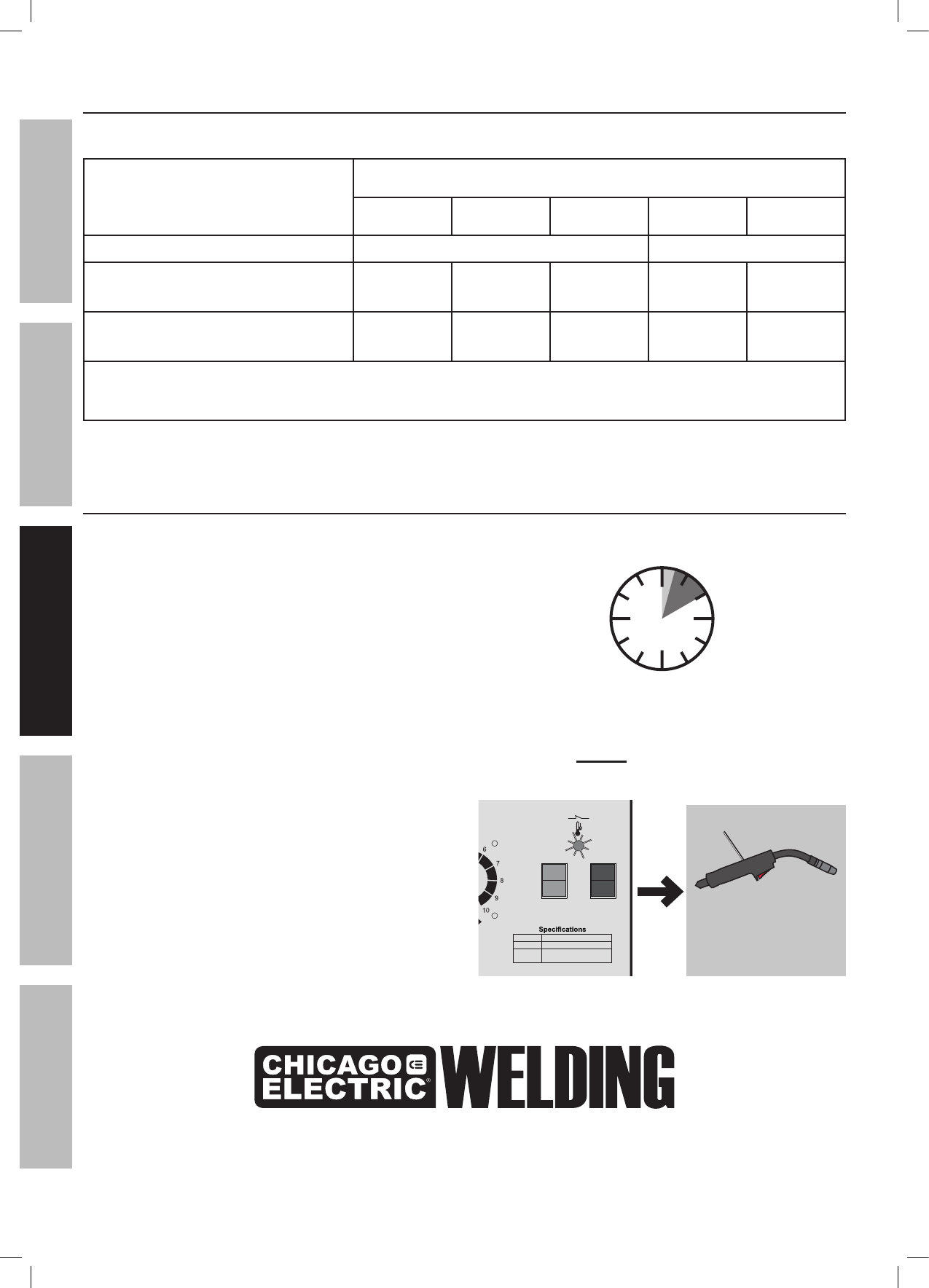

Weld Settings Chart

NOTE: The numbers within the

spaces are the approximate wire

feed settings recommended* for this

wire size and material thickness.

Material Thickness (Steel)

18 Gauge 16 Gauge 14 Gauge

1

/

8

″

3

/

16

″

MIN current MAX current

.030″ Wire Size

(Flux Core, Mild Steel)

1.5

speed

2

speed

4

speed

8

speed

9

speed

.035″ Wire Size

(Flux Core, Mild Steel)

1.5

speed

2

speed

3

speed

8

speed

9.5

speed

* This chart is only intended to show general guidelines for different wire sizes and for different

thicknesses of material. The settings should only be used at the beginning of a weld and must be

adjusted after stopping and carefully inspecting the weld. Proper welding takes experience.

Duty Cycle (Duration of Use)

Avoid damage to the Welder by not welding

for more than the prescribed duty cycle time.

The Duty Cycle defines the number of minutes, within

a 10 minute period, during which a given welder can

produce a particular welding current without overheating.

For example, this Welder with a 20% duty cycle at

rated output (90A) must be allowed to rest for at

least 8 minutes after every 2 minutes of continuous weld.

Failure to carefully observe duty cycle limitations

can easily over-stress a welder’s power generation

system contributing to premature welder failure.

This welder has an internal thermal protection

system to help prevent this sort of over-stress.

When the unit overheats, it automatically shuts down and

the Overload Indicator lights. The welder automatically

returns to service after cooling off. Rest the Gun on

an electrically non-conductive, heat-proof surface,

such as a concrete slab, well clear of the ground clamp

while allowing the welder to cool with the Power Switch

on, so that the internal Fan will help cool the welder.

When the welder can be used again, use shorter welding

periods and longer rest periods to prevent needless wear.

20% Rated Duty Cycle

at 90A output

2 minutes welding

followed by

at least 8 minutes of rest

ON MIN

OFF MAX

WIRE FEED SPEED

GUN

GROUND

120V~

60Hz

20A

90 AMP FLUX WIRE WELDER

ITEM 68887

Wire .030″-.035″ Flux-core

Capacity XX Ga. – X/X″ Steel Plate

Cables

Electrode – X′

Ground Clamp – X′

Gun

concrete slab

(or other heat-proof,

non-conductive

surface)

SAFETY MAINTENANCEBASIC WELDING WELDING TIPSSETUP