RLL233 Issue 4 Aug 2007

2

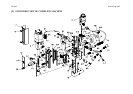

[1] ROTABROACH MAGNETIC DRILLING MACHINE

MODELS CM/200/1/ & CM/200/3

Maximum hole cutting capacity in .2/.3C steel = 65mm dia. x 50mm deep

Arbor bore = 19.05mm (3/4") dia.

Motor Unit

Voltages

110v

230v

normal full load

14 A

1400 W

6 A

1400 W

Electro Magnet

0.6A

69W

0.3A

69W

Size

180mm long

90mm wide

Tractive Force at 20°C with 25mm

minimum plate thickness

The use on any material less than 25mm thick will

progressively reduce the magnetic performance. If

possible, substitute material should be positioned under

the magnet and work piece to equate to a suitable

material thickness. If this is not possible, an alternative

secure method of restraining the machine MUST be

used.

1200kgs

Total Load (magnet + motor)

1469 W

1469 W

Overall Dimensions

Height - maximum extended

550mm

Height - minimum

470mm

Width (including Hand wheel)

200mm

Length Overall (including Guard)

270mm

Nett Weight

16kgs

Maximum hand/arm vibration magnitude (measured at

handle during operation in accordance with ISO5349,

using a 22mm cutter through 13mm MS plate)

0.82 m/s_

Estimate of likely daily vibration exposure. Operation

30 holes @ 2 minute/hole.

0.29m/s_ A(8)

Average noise level during cutting at operators ear

position.

89dB(A)

Ear defenders must be worn when operating this machine

These tools are UK designed, and manufactured with globally sourced components and

conform with the requirements of EEC Document HD.400.1 and BS.2769/84

Suitable only for a single phase 25-60Hz A.C. power supply

DO NOT USE ON D.C. SUPPLY

Do not use your magnetic drill on the same structure when arc welding is in progress.

D.C. current will earth back through the magnet and cause irreparable damage.

WARNING: THIS APPLIANCE MUST BE EARTHED!

NB: ANY MODIFICATIONS TO THIS MACHINE WILL INVALIDATE THE GUARANTEE