CLAMPING SCROLL SAW TO

WORKBENCH

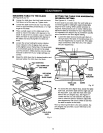

See Figure 7.

If the scroll saw is to be used in a portable application,

we recommend that you fasten it permanently to a

mounting board that can easily be clamped to a

workbench or other supporting surface. The mounting

board should be of sufficient size to avoid tipping of

saw while in use.

• Mount saw to board using holes in frame as a

template for hole pattern or the diagram in

Figure 6. Locate and mark the holes where scroll

saw is to be mounted.

• Follow last three steps in previous section called

Mounting Scroll Saw to Workbench.

Make sure mounting bolts are long enough to go

through holes in the saw frame, material being

mounted to, lock washers, and hex nuts.

Note: It may be necessary to countersink hex nuts

and washers on bottom side of mounting board.

\

C-CLAMP

C-CLAMF

WORKBENCH

MOUNTING

BOARD

Fig. 7

_1, WARNING: To prevent accidental starting that

could cause possible serious personal injury,

turn off the saw and unplug before making any

adjustments.

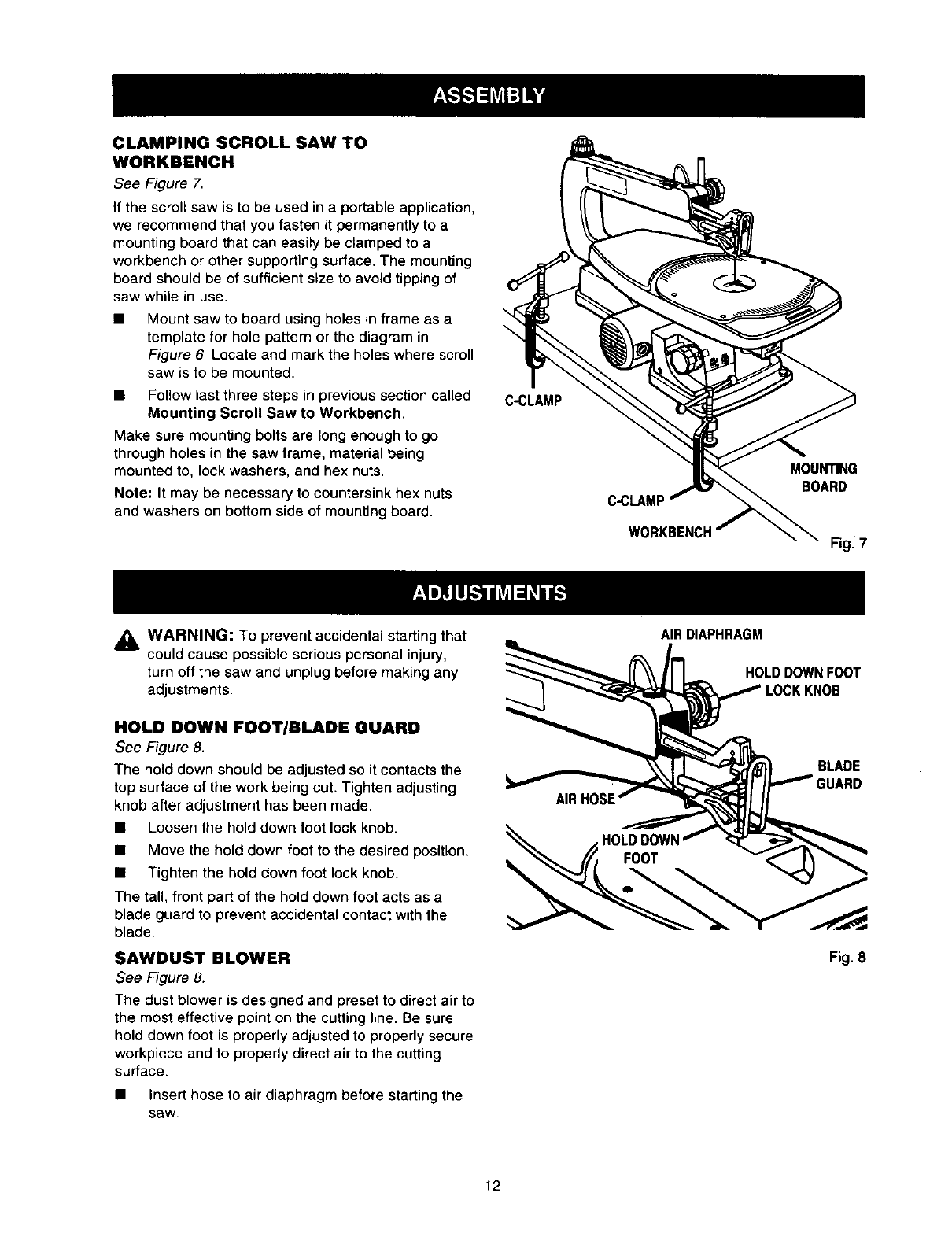

HOLD DOWN FOOT/BLADE GUARD

See Figure 8.

The hold down should be adjusted so it contacts the

top surface of the work being cut. Tighten adjusting

knob after adjustment has been made.

• Loosen the hold down foot lock knob.

• Move the hold down foot to the desired position.

• Tighten the hold down foot lock knob.

The tall, front part of the hold down foot acts as a

blade guard to prevent accidental contact with the

blade.

SAWDUST BLOWER

See Figure 8.

The dust blower is designed and preset to direct air to

the most effective point on the cutting line. Be sure

hold down foot is properly adjusted to properly secure

workpiece and to properly direct air to the cutting

surface.

• Insert hose to air diaphragm before starting the

saw.

\

AIR HOSE

AIR DIAPHRAGM

HOLD DOWN FOOT

BLADE

Fig. 8

12