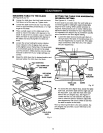

SQUARING TABLE TO THE BLADE

See Figures 9 and 10.

• Loosen the hold down foot lock knob and move

hold down rod all the way up. Tighten knob.

• Loosen the table lock knob and move the table

untit it is approximately perpendicular, or at right

angle to the blade.

• Place a small square on the table next to the

blade to check if the table is 90 degrees to the

blade. If adjustment is needed, raise or lower the

table until table is approximately go degrees to

the blade and securely tighten the table lock

knob.

Loosen the screw holding the scale indicator,

move indicator to the 0 degree mark and se-

curely tighten screw. Remember, the bevel scale

is a convenient guide but should not be relied

upon for precision. Make practice cuts on scrap

materiat to determine if your angle settings are

correct.

• Adjust the hold down foot to desired position and

securely tighten the hold clown foot knob.

HOLDDOWNROD

HOLDDOWNFOOT

COMBINATION

SQUARE

HOLDDOWN

FOOT/

BLADEGUARD

SAW BLADE

TABLELOCK

KNOB

Fig. 9

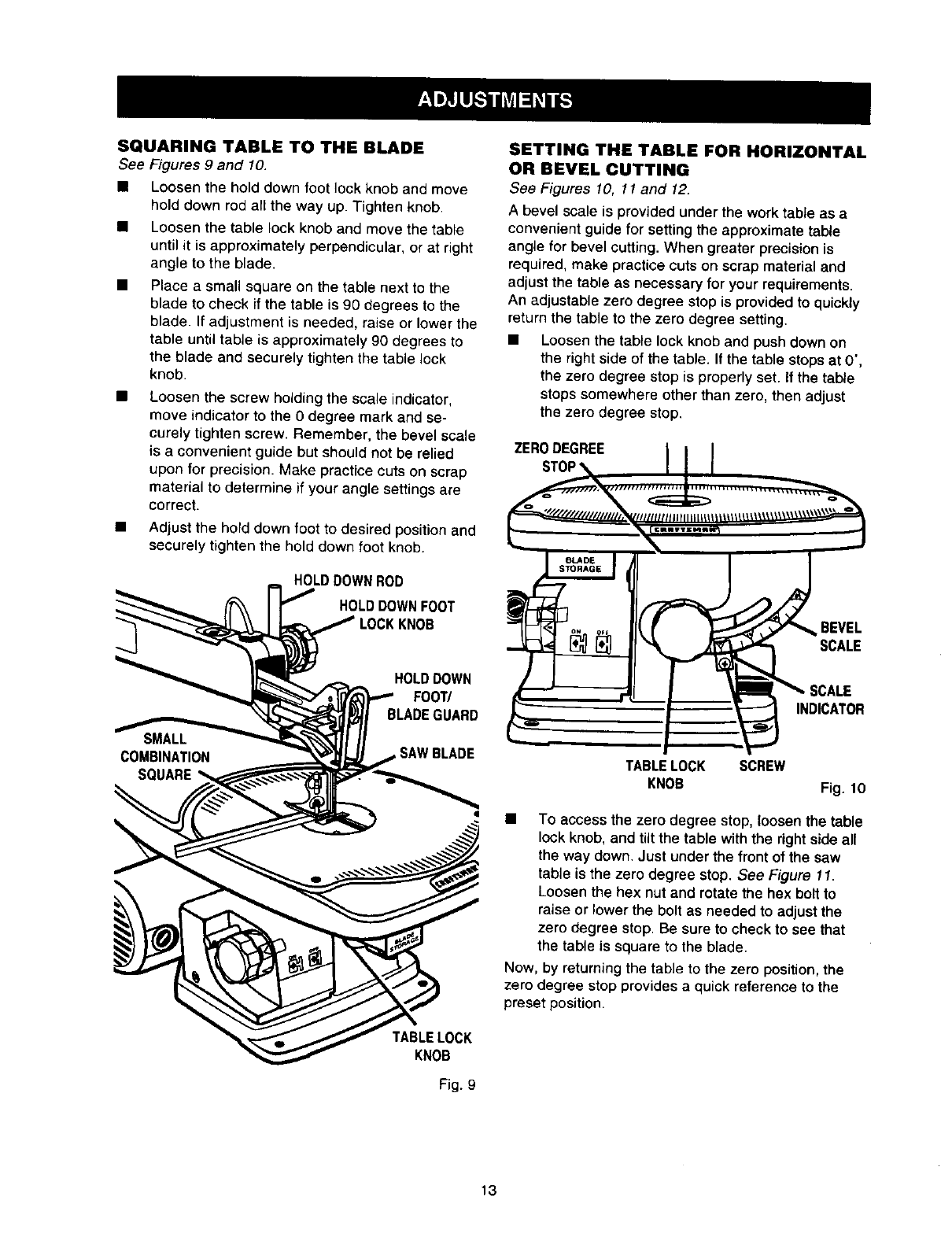

SETTING THE TABLE FOR HORIZONTAL

OR BEVEL CUTTING

See Figures 10, 11 and 12.

A bevel scale is provided under the work table as a

convenient guide for setting the approximate table

angle for bevel cutting. When greater precision is

required, make practice cuts on scrap material and

adjust the table as necessary for your requirements.

An adjustable zero degree stop is provided to quickly

return the table to the zero degree setting.

• Loosen the table lock knob and push down on

the right side of the table. If the table stops at 0 °,

the zero degree stop is properly set. If the table

stops somewhere other than zero, then adjust

the zero degree stop.

ZERODEGREE II /

SCALe

_ __ INDICATOR

TABLE LOCK SCREW

KNOB Fig. 10

• To access the zero degree stop, loosen the table

lock knob, and tilt the table with the right side all

the way down. Just under the front of the saw

table is the zero degree stop. See Figure 1I.

Loosen the hex nut and rotate the hex bolt to

raise or lower the bolt as needed to adjust the

zero degree stop. Be sure to check to see that

the table is square to the blade.

Now, by returning the table to the zero position, the

zero degree stop provides a quick reference to the

preset position.

13