machine. It is recommended that machines which produce

greater amounts of dust be located closest to the dust collec-

tor.

WARNING: There is a danger of static electricity building up

in the dust collector system and causing a flash explosion or

fire. To prevent static electricity buildup, install grounding kit.

• A grounding kit is included and must be installed in the

shop dust collector system to protect against electrostatic

discharge. The grounding kit is more easily installed as the

individual sections for each machine are assembled.

LAYOUT SYSTEM AT SELECTED SITE

Temporarily assemble the pieces together as described below

so that the location of the hangers can be determined and

where the wall anchors for the hangers will be placed.

• Attach 2_/2x 22" plastic straight pipe to 45-degree elbow

using connector.

• Attach 2W' plastic "T" fitting to 2_/2x 22" plastic straight

pipe using connector.

• Repeat steps 2 and 3 for connection to each additional

machine.

• For last machine, attach 45 ° elbow to 2_/2x 22" plastic

straight pipe using connector.

• Prop plastic pipe and "T" fitting temporary assembly with

2 x 4's against wall. inlet should be less than 24" from dust

collector.

• Position hangers approximately 6" from each end of 2_/zx

22" straight plastic pipe and mark hole locations for each

hanger.

INSTALL WALL ANCHORS

Wall anchors need to be installed at the site selected for the

dust collector. To install wall anchors:

* Drill 3/j, hole, 1_/4"deep at each hanger mark.

. Hammer anchors into each of the holes, so that they are

flush with wall.

PERMANENT ASSEMBLY

Refer to Figures 1 and 2.

• Mount first section of plastic straight pipe and "T" fitting

using hangers and thread-forming screws into wall anchors.

• Drill _/J' hole in first section of plastic straight pipe where it

meets the "T" fitting.

• Cut grounding wire to a length of 4' for plastic pipe, plus

length of hose that attaches from pipe to dust collector.

• Run the grounding wire inside the plastic straight pipe and

hose to the dust collector.

• Drill _/_"holes in the hose on dust collector side and bring

grounding wire out through hole.

• Attach hose from pipe to dust collector.

• Attach end of grounding wire to metal screw on the dust

collector.

• Bring other end of grounding wire out through the W'

drilled hole.

• Mount additional sections of plastic straight pipe and "T"

fittings using hangers and thread-forming screws into wall

anchors.

• Drill _/_"hole in both ends of each section of plastic straight

pipe where it meets the "T" fitting.

• Run a 4' length of grounding wire inside each plastic

straight pipe.

• Bring each end of grounding wire out through the W'

drilled holes.

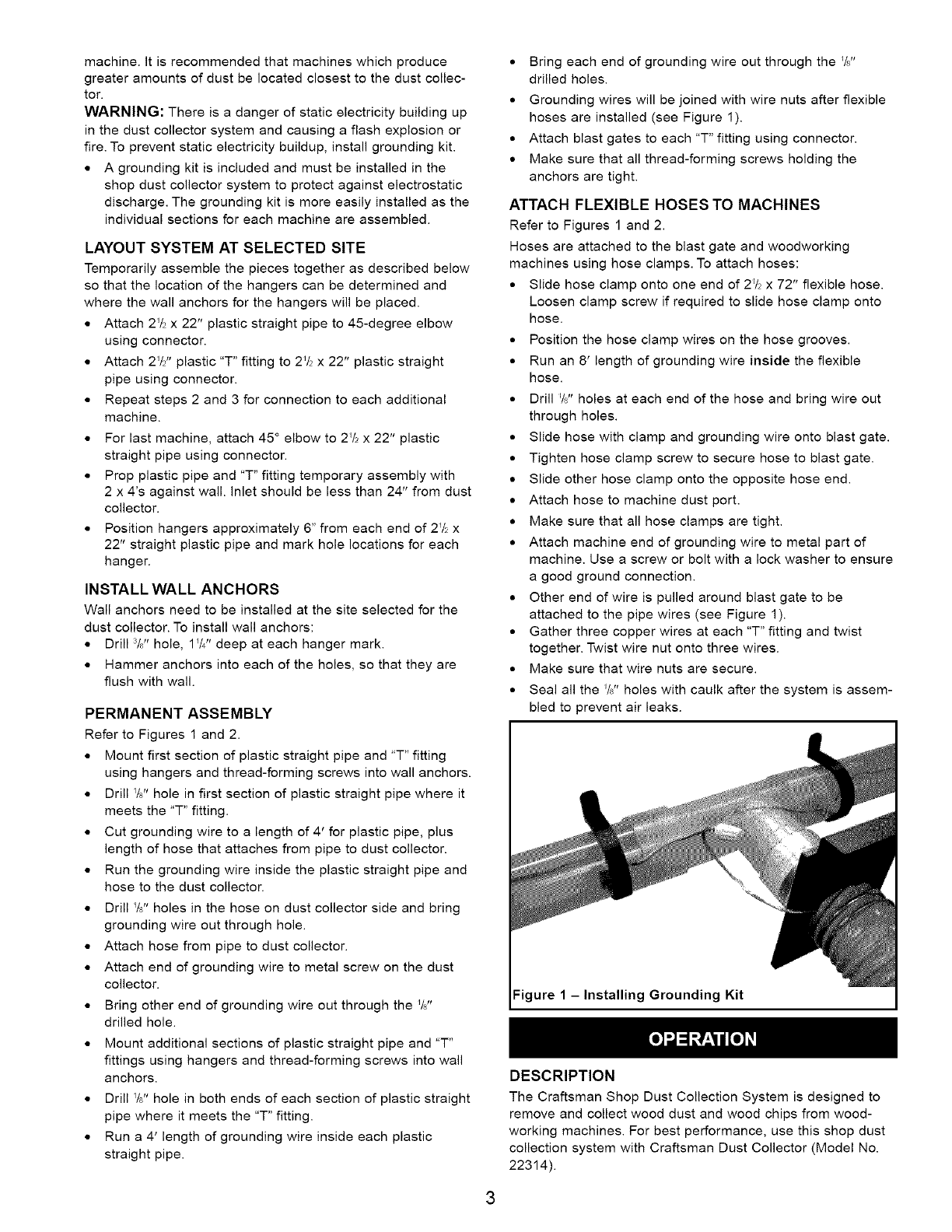

• Grounding wires will be joined with wire nuts after flexible

hoses are installed (see Figure 1).

• Attach blast gates to each "T" fitting using connector.

• Make sure that all thread-forming screws holding the

anchors are tight.

ATTACH FLEXIBLE HOSES TO MACHINES

Refer to Figures 1 and 2.

Hoses are attached to the blast gate and woodworking

machines using hose clamps. To attach hoses:

• Slide hose clamp onto one end of 2_t_x 72" flexible hose.

Loosen clamp screw if required to slide hose clamp onto

hose.

• Position the hose clamp wires on the hose grooves.

• Run an 8' length of grounding wire inside the flexible

hose.

• Drill W' holes at each end of the hose and bring wire out

through holes.

• Slide hose with clamp and grounding wire onto blast gate.

• Tighten hose clamp screw to secure hose to blast gate.

• Slide other hose clamp onto the opposite hose end.

• Attach hose to machine dust port.

• Make sure that all hose clamps are tight.

• Attach machine end of grounding wire to metal part of

machine. Use a screw or bolt with a lock washer to ensure

a good ground connection.

• Other end of wire is pulled around blast gate to be

attached to the pipe wires (see Figure 1).

• Gather three copper wires at each "T" fitting and twist

together. Twist wire nut onto three wires.

• Make sure that wire nuts are secure.

• Seal all the W' holes with caulk after the system is assem-

bled to prevent air leaks.

ure 1 - Installing Grounding Kit

DESCRIPTION

The Craftsman Shop Dust Collection System is designed to

remove and collect wood dust and wood chips from wood-

working machines. For best performance, use this shop dust

collection system with Craftsman Dust Collector (Model No.

22314).