22

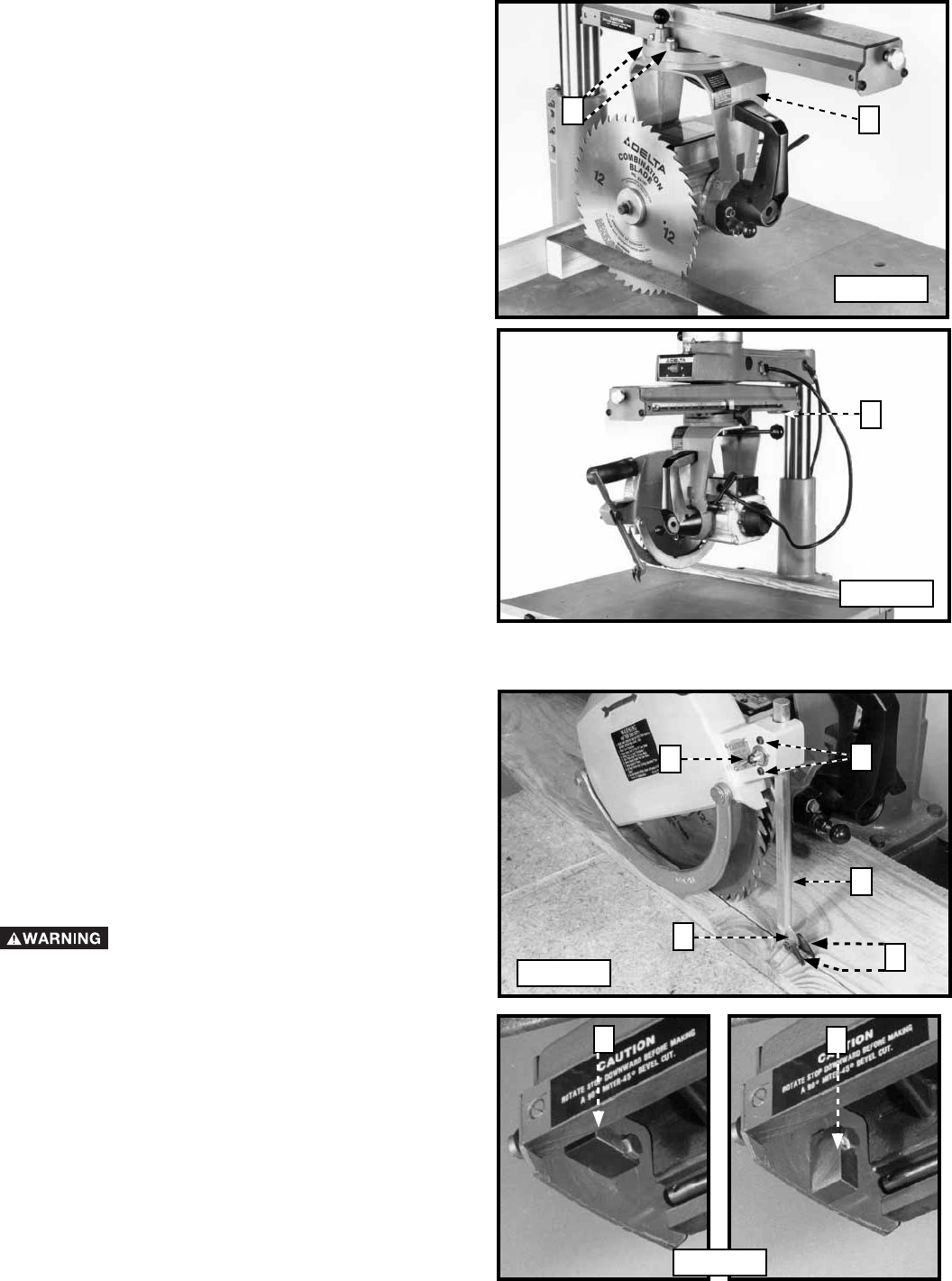

3. To adjust, loosen the yoke-clamping handle and the

two screws (C) Fig. 54. Swivel the yoke (D) until the

saw blade is parallel with the square. Tighten the

yoke-clamping handle and the two screws (C) Fig.

54.

CROSS-CUT STOP

A block of wood placed at (B) Fig. 55 (clamped to the

track arm with a small “C” clamp) will prevent unnecessary

travel of the cutting-head on the track arm. This is

especially useful when performing repetitive operations.

Clamp the block of wood to the right side of the track

arm at a position which will stop the cutting-head travel as

soon as the saw blade cuts through the workpiece.

On all ripping and plowing operations, lower the infeed

side of the blade guard so that it just clears the material

to prevent the material from being lifted off the table.

Lower the kickback rod (A) Fig. 56 so that the kickback

fingers (B) are below the surface of the workpiece.

Loosen the wing nut (C) to raise or lower the rod (A).

Move the kickback rod to the desired position and

tighten the wing nut. This action will allow the kickback

fingers (B) to come into contact with the workpiece,

preventing “kickback.” The splitter (D) Fig. 56 should be

in line with the saw blade. To adjust:

Disconnect the machine from the power

source!

Tighten or loosen the two screws (E) Fig. 56 on the Rod

(A).

ADJUSTING THE TRACK ARM STOP

To make cuts with the track arm in the straight cut-off

position and the motor tilted for a 45° bevel cut, rotate

the stop (A) Fig. 57 to the "down" position to prevent the

saw blade from contacting the column.

Fig. 54

D

C

B

ADJUSTING THE BLADE GUARD AND THE ANTI-KICKBACK ROD

Fig. 55

Fig. 56

Fig. 57

C

E

A

D

A

A

B