27

TROUBLESHOOTING

For assistance with your tool, visit our website at www.deltamachinery.com for a list of service centers or call the DELTA

Machniery help line at 1-800-223-7278 (In Canada call 1-800-463-3582).

MAINTENANCE

KEEP MACHINE CLEAN

Periodically blow out all air passages with dry compressed air. All plastic parts should be cleaned with a soft damp cloth. NEVER

use solvents to clean plastic parts. They could possibly dissolve or otherwise damage the material.

Wear ANSI Z87.1 safety glasses while using compressed air.

LUBRICATION

Apply household floor paste wax to the machine table and extension table or other work surface weekly.

PROTECTING CAST IRON FROM RUST

To clean and protect cast iron tables from rust, you will need the following materials: 1 pushblock from a jointer, 1 sheet of medium

Scotch-Brite™ Blending Hand Pad, 1 can of WD-40

®

, 1 can of degreaser, 1 can of TopCote

®

Aerosol. Apply the WD-40 and polish

the table surface with the Scotch-Brite pad using the pushblock as a holddown. Degrease the table, then apply the TopCote

®

accordingly.

G

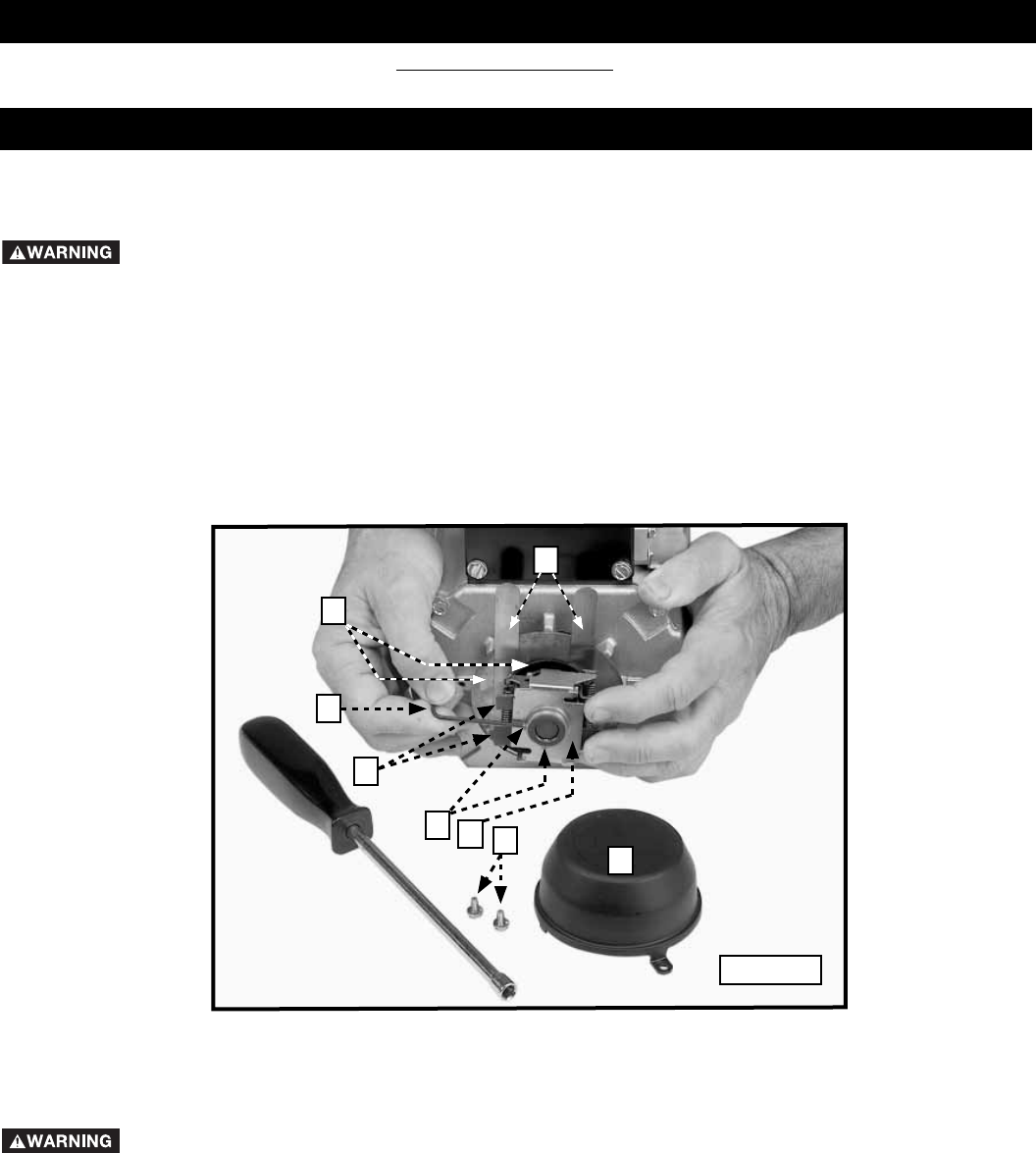

BRAKE SERVICE

C

H

D

E

A

B

F

Disconnect the machine from the power source!

The motor on this product is equipped with an external mechanical braking device. To adjust:

1. Remove the two screws (A) Fig. 65 securing the plastic brake mechanism cover (B). Remove the cover.

2. Use 5/64" hex wrench (C) to loosen the two (2) set screws (D).

3. Slide brake mechanism (E) off of the shaft. Inspect phenolic shoe. Replace the brake mechanism if the shoe is damaged or

excessively worn.

4. Clean the brake shoe and the brake disc (F) to remove any dust and oil build up.

5. Place the disc and brake mechanism on the shaft. Place two .020" shims (G) between the disc and brake shoe. See the photo

above for proper shim placement.

6. Push the brake mechanism toward the disc until the flyweights (H) expand and you feel firm resistance. Carefully hold the

brake mechanism in this position while securely tightening the two setscrews loosened in Step 3.

7. Remove the two shims and replace the plastic cover, taking care to center the brake disc in the shoulder around the

plastic cover outer-circumference.

8. Test run the motor to ensure that the brake does not drag during operation.

Fig. 65

FAILURE TO START

Should your machine fail to start, check to make sure the prongs on the cord plug are making good contact in the outlet. Also, check

for blown fuses or open circuit breakers in the line.