20

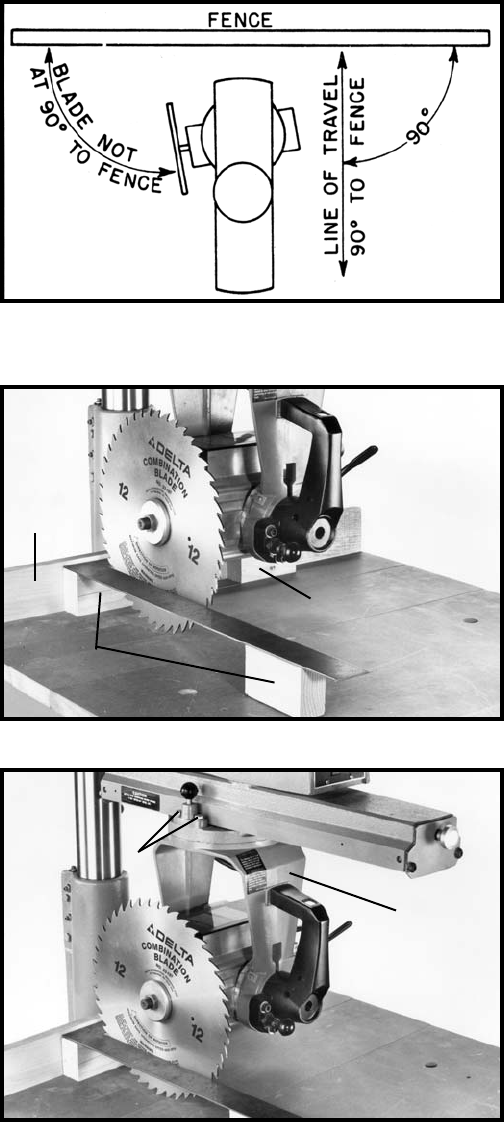

Fig. 54

Fig. 55

Fig. 56

REMOVING “HEELING”

IN SAW CUT

Even though the cuttinghead travel may be perfectly

aligned at 90 degrees to the fence, the blade itself may

not be 90 degrees or square with the fence, as shown in

Fig. 54. This condition is known as “heeling.”

To check and adjust, proceed as follows:

1. DISCONNECT TOOL FROM POWER SOURCE.

2. Take a piece of 3/4” plywood or similar piece of

wood (A) Fig. 55, at least 5” wide, and clamp it between

the table boards in place of the fence, as shown.

3. Using three 2 x 4’s four inches in height, as shown at

(B) Fig. 55, lay a square on the 2 x 4’s with one end of the

square against the plywood (A) and the other end against

the saw blade, as shown in Fig. 55.

4. If the blade is not parallel to the square, an

adjustment is necessary. Loosen yoke clamping handle

and the two screws (C) Fig. 56. Swivel the yoke (D) until

the saw blade is parallel with the square. Then tighten

yoke clamping handle and two screws (C) Fig. 56.

CROSS-CUT STOP

A block of wood clamped to the track arm with a small “C” clamp will prevent unnecessary travel

of the cuttinghead on the track arm. This is especially useful when performing repetitive cutting

operations. Clamp the block of wood to the right side of the track arm at a position which will stop

the cuttinghead travel as soon as the saw blade cuts through the workpiece.

A

B

B

D

C