18

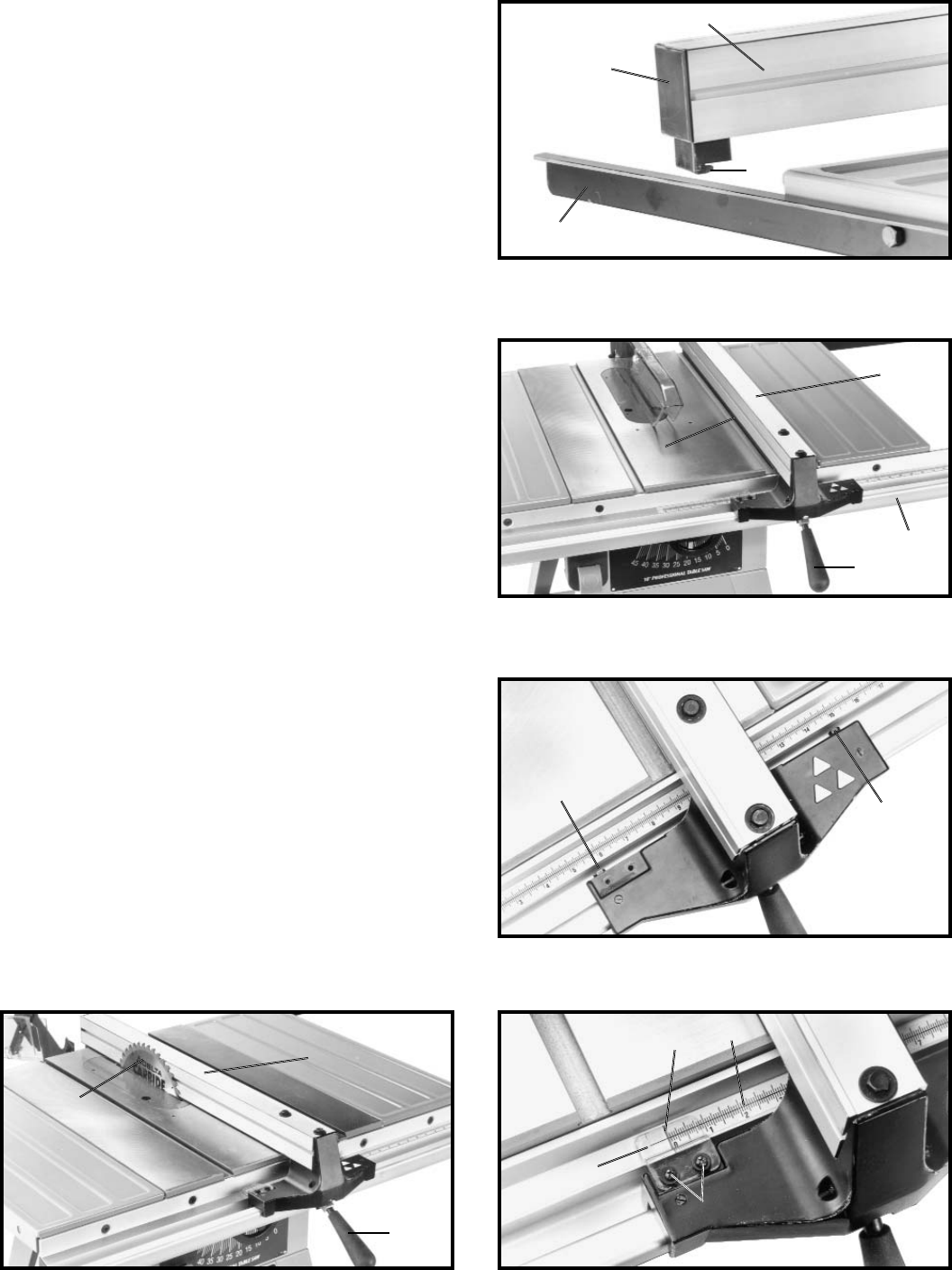

3. Lower the front of rip fence (B) Fig. 46, onto the front

guide rail (L).

4. Lock the rip fence (B) Fig. 46, on the guide rails by

pushing down handle (A).

RIP FENCE TO GUIDE RAILS

1. Insert end cap (A) Fig. 45, into back of rip fence (B).

2. With the fence handle (A) Fig. 46, in the raised

position, place the rip fence (B) onto the rear guide rail

(C) so the hooked end (D) Fig. 45, fits over the top ledge

of the guide rail as shown.

5. Slide rip fence (B) Fig. 46, against one edge of the

miter gage slot (C) as shown. Clamp the fence onto the

guide rail by pushing down on lock handle (A). The edge

of the fence (B) Fig. 46, should line up so it is parallel

with the edge of the miter gage slot. If an adjustment is

necessary, tighten or loosen either of two screws (D)

Fig. 47, as necessary until rip fence (B) Fig. 46, lines up

with the miter gage slot. NOTE: Cursor has been

removed for clarity.

6. Once the rip fence is aligned with the miter gage

slot, raise the saw blade (E) Fig. 48, to its highest

position, as shown. Slide rip fence (B) against the saw

blade (E) and lock the fence in that position by pushing

down on handle (A).

7. The cursor witness line (F) Fig. 49, should line up

with the “zero” mark on scale (G). If the witness line does

not line up with the “zero” line on the scale, loosen two

screws (H) and adjust cursor (K).

Fig. 45

B

A

C

D

Fig. 46

B

C

A

L

Fig. 47

D

D

Fig. 48 Fig. 49

A

B

E

H

K

F

G