7

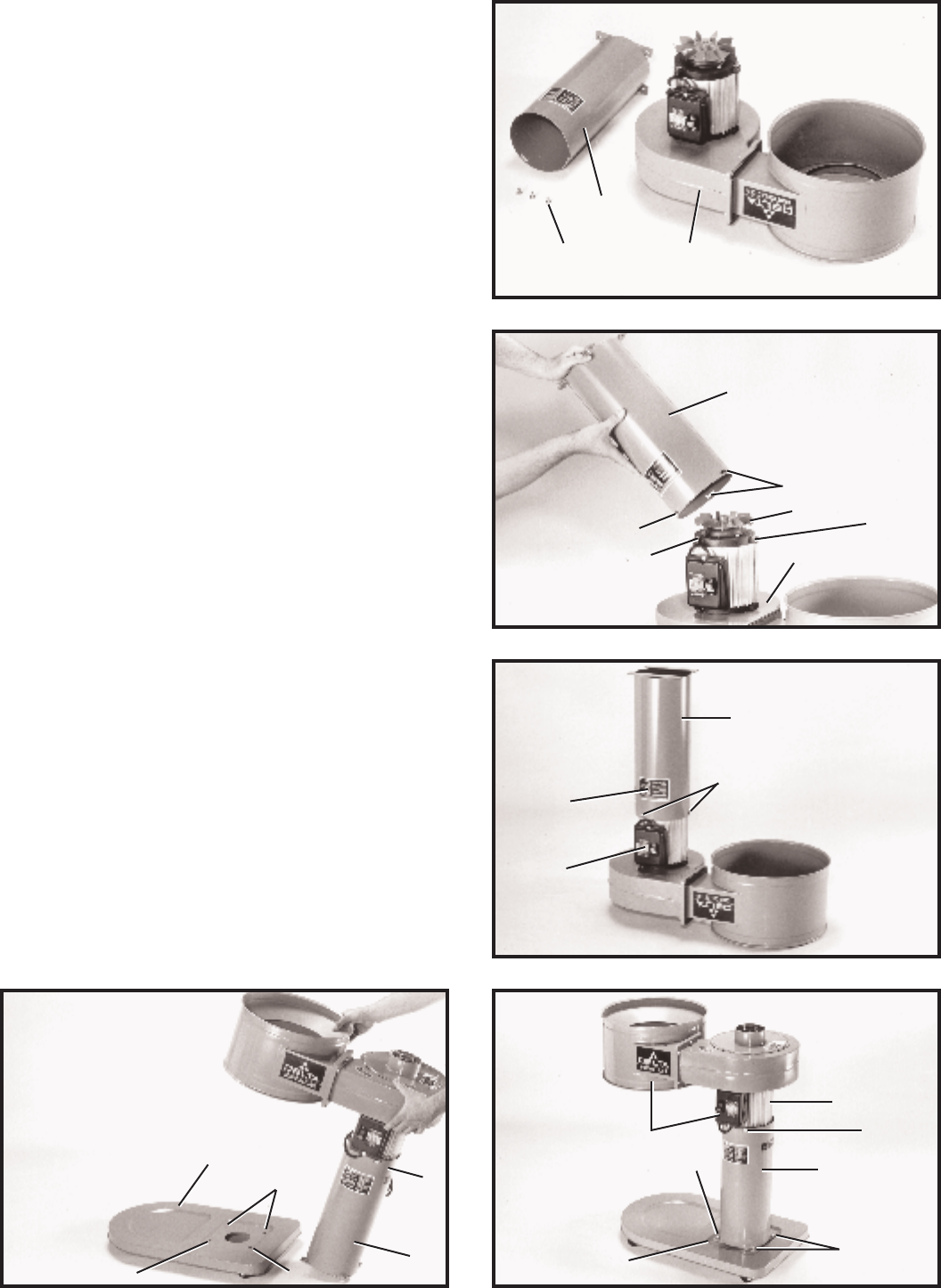

ASSEMBLING

SUPPORT TUBE A N D

MOTO R AND BLOWER

ASSEMBLY TO BASE

1. Place the motor and blower assembly (A) Fig. 5,

upside down on a sturdy supporting surface.

2. Find the support tube (B) Fig. 5, and three 1/2 inch-

long hex head screws (C).

3. Carefully place support tube (B) Fig. 6, over the moto r

impellers (D). Align three holes (E) Fig. 6, in support tube

(B) with three holes in the motor casting, two of which are

shown at (F) and fasten support tube (B) to motor and

blower assembly (A) with three 1/2 inch-long screws

(C) Fig. 7. Warning label (K) Fig. 7, should be positioned

over the on/of f switch (L) when support tube (B) is prop -

erly positioned as shown. NOTE: Do not tighten three

screws, two of which are shown at (C) Fig. 8, at this time.

4. Carefully turn motor and blower assembly (A) Fig. 8,

with support tube (B) att ached, right side up. Align the

four holes in the feet of support tube (B) Fig. 8, with four

threaded holes (K) in base and fasten motor and blower

assembly (A) Fig. 9, to base (L) with four 5/16-18 x 1/2

hex head screws, three of which are shown at (M).

5. IMPORTANT:Make certain motor and blower assem-

bly (A) Fig. 9, is p arallel with base (L). If adjustment is

necessary, rotate motor (N) on support tube (B) and

tighten three mounting screws, one of which is shown

at (C).

Fig. 5

Fig. 6

Fig. 7

Fig. 9Fig. 8

C

B

A

B

E

E

D

F

A

C

K

L

K

K

K

L

A

B

N

C

B

M

M

L

A

F

B