10

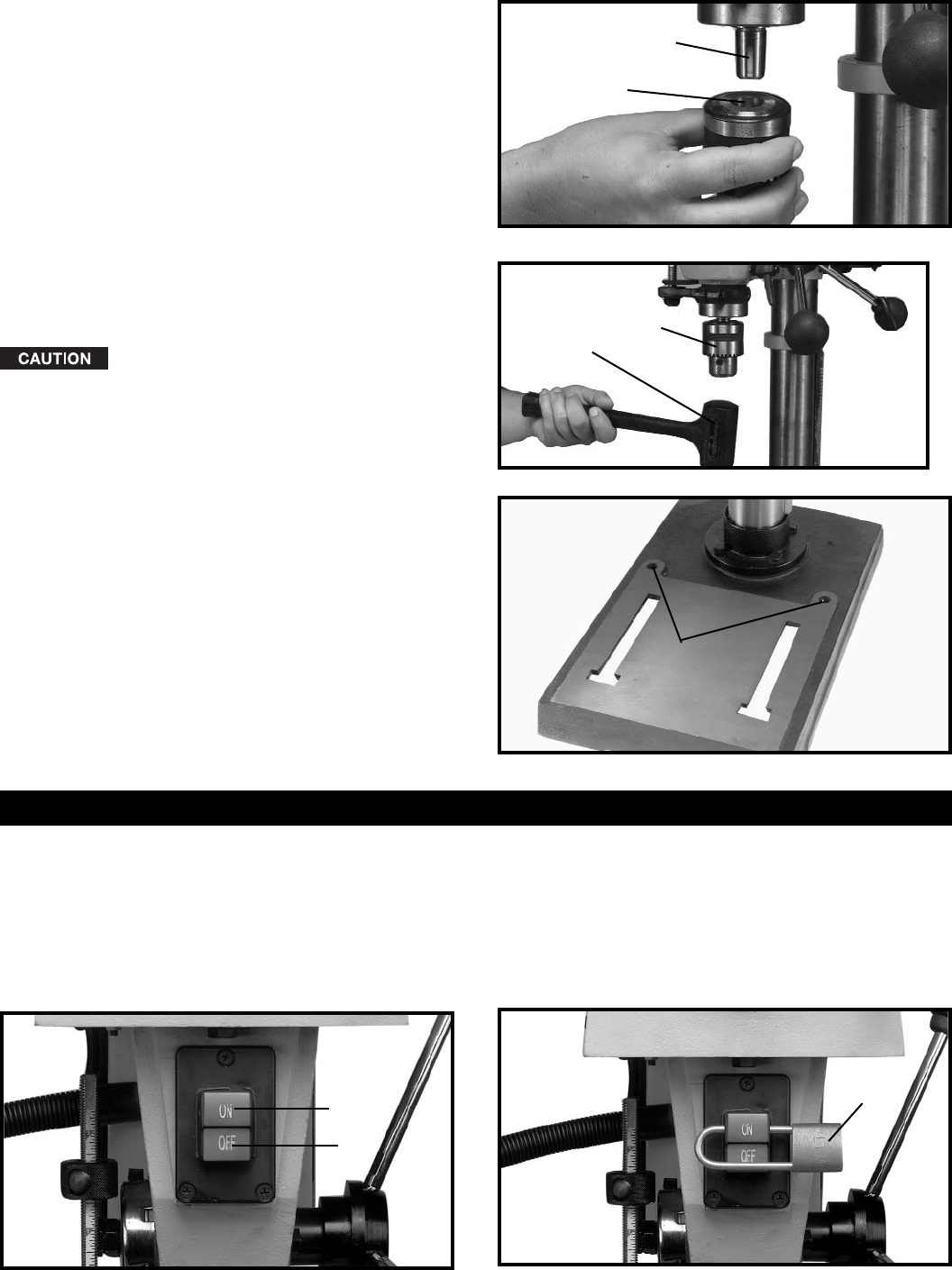

10. IMPORTANT: Make certain the spindle taper (Q) Fig.

15, and tapered hole in chuck (R) are clean and free of

any grease, lacquer or rust preventive coatings. NOTE:

Household oven cleaner can effectively remove any sub-

stance from the spindle and chuck; however, carefully

follow the manufacturer's safety rules concerning its

use.

11. IMPORTANT: Open the chuck jaws as wide as

possible by turning the chuck sleeve (S) Fig. 16.

12. Holding chuck on taper of spindle, tap with a soft tip

hammer (T) or a block of wood and hammer to set

chuck, as shown in Fig. 16.

To avoid damage to the chuck, NEVER

drive the chuck onto the spindle with a metal hammer.

Fig. 15

Fig. 16

OPERATING CONTROLS AND ADJUSTMENTS

Fig. 17

STARTING AND STOPPING

DRILL PRESS

The power switch is located at the front of the drill press

head. To turn the drill press “ON”, press the green start

button (A) Fig. 17. To stop the drill press, push the red

button (B).

Fig. 18

LOCKING SWITCH IN

THE “OFF” POSITION

IMPORTANT: When the machine is not in use, the switch

should be locked in the OFF position using a padlock (C)

Fig. 18, with a 3/16" diameter shackle to prevent

unauthorized use.

Q

R

S

T

FASTENING DRILL PRESS

TO SUPPORTING SURFACE

If during operation there is any tendency for the machine

to tip over, slide or walk on the supporting surface, the

machine base must be secured to the supporting

surface with a M8x1.25x125mm carriage head screw,

8.5mm flat washer, 8.5mm lock washer, M8x1.25 hex

nut, through the two holes (A) Fig. 16A, located in the

machine base.

Fig. 16A

A

A

B

C