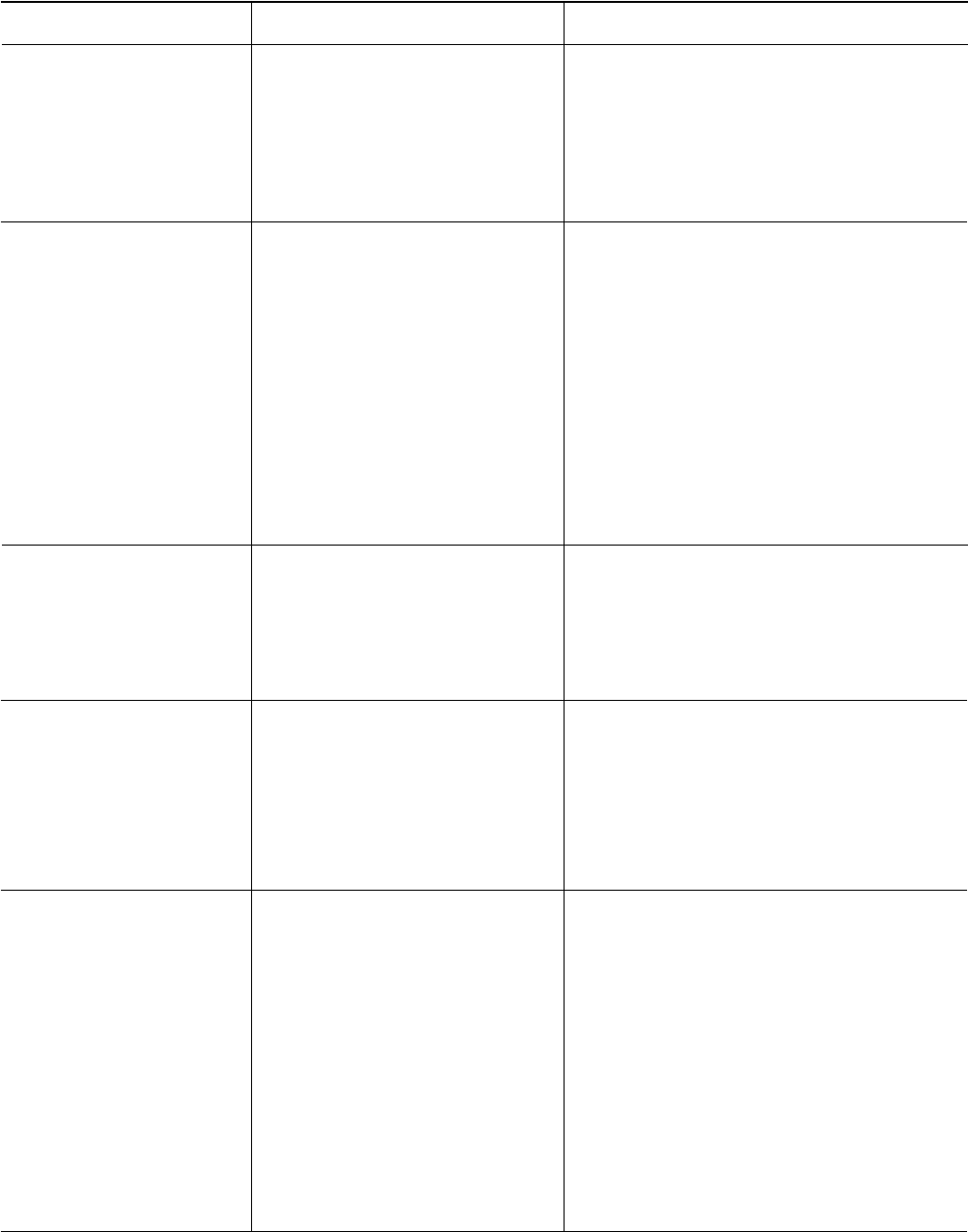

20—ENG

CORRECTION

CAUSEPROBLEM

TROUBLESHOOTING GUIDE

Compressor is not supplying

enough air to operate accesso-

ries. (Continued)

Loose belt.

Hole in hose.

Check and replace if required.

Check valve restricted.

Adjust belt tension.

Remove and clean or replace.

Tighten fittings. (See "Air Leaks" section of "Trou-

bleshooting Guide".)

Air leaks.

Maintain prescribed oil level. Add oil.

Knocking noise.

Defective check valve.

Remove and clean or replace.

Tighten pulley set screw, 145 to 165 in.-lbs.Loose pulley.

Low oil level.

Loose flywheel.

Tighten screw, 33 to 37 ft.-lbs.

Loose compressor mounting screws.

Check screws. Tighten as required.

Belt too tight/too loose.

Adjust belt tension. (See Belt Replacement.)

Carbon build-up.

Remove the head and valve plate. Clean the valve

plate and the top of the piston. (Be sure carbon does

not fall into the cylinder.) Reassemble using new

gaskets and torque screws, 30 to 39 ft.-lbs.

Excessive oil consumption. Replace the air intake.

Restricted air intake.

Reduce air consumption or add another air com-

pressor to take up some of the load.

Compressor overworked.

Drain pump and replace with correct oil. Refer to

Lubrication and Oil Section.

Poor quality oil.

Compressor overheating.

The compressor is overworked. Reduce air consumption or add another air com-

pressor to take up some of the load.

Inspect the check valve. Clean if necessary.

Dirty compressor. Clean the compressor thoroughly.

High ambient temperature.

Use remote air intake.

The check valve is restricted.

Incorrect oil, low oil. See oil recommendation on page 14.

Motor overheating.

Dirty or defective check valve.Compressor starting against load.

Low voltage.

Provide correct voltage. Consult local power com-

pany or electrician.

Do not set switch beyond maximum for which outfit

was designed as noted on nameplate.

Pressure switch set beyond factory

setting.

Belt too tight.

Adjust for proper tension.

Compressor valves have excessive

carbon deposits build-up; restricted

check valve.

Clean or replace compressor valves or check valve.