7

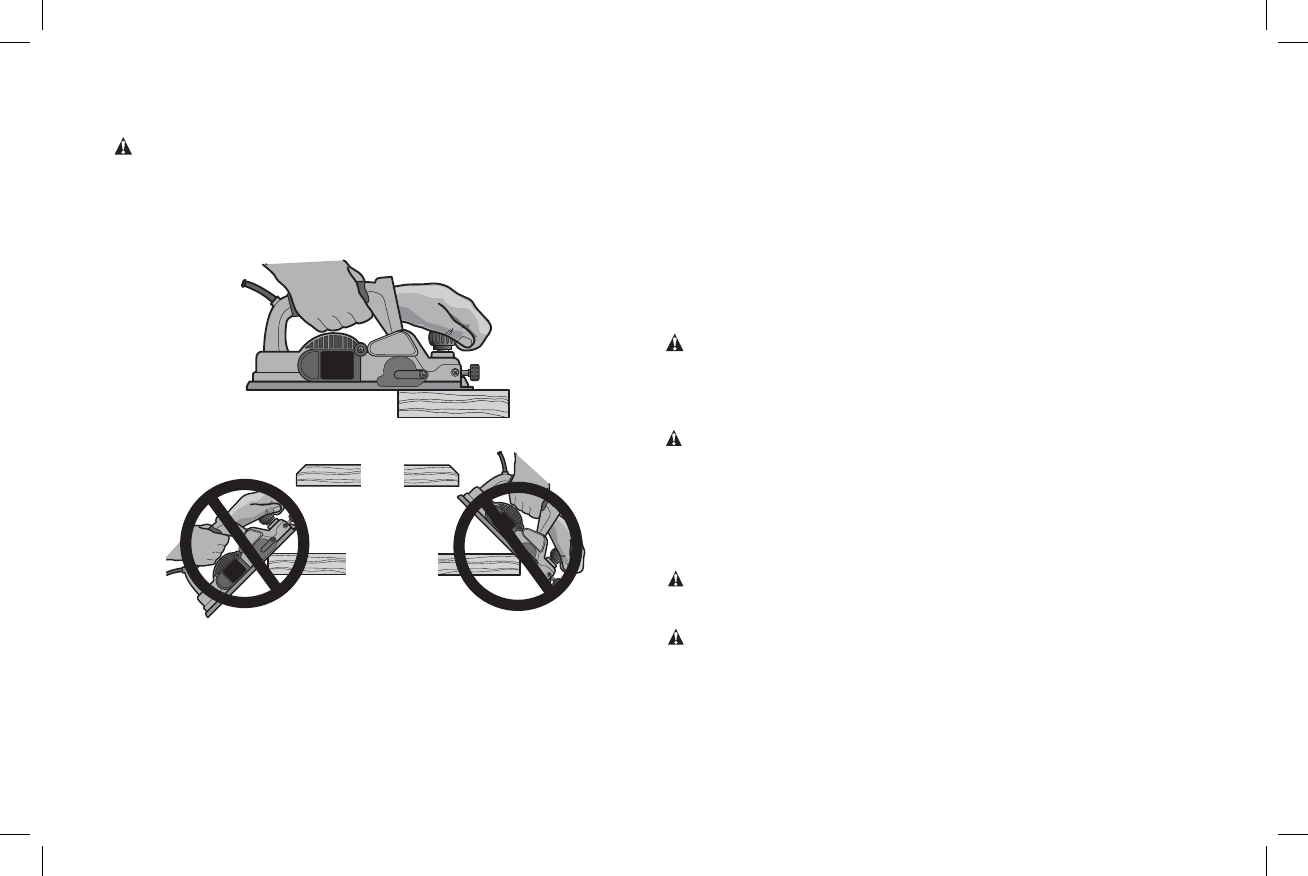

Planing (Fig. 1, 7)

CAUTION: Risk of property damage. Allow the tool to reach full speed before

touching tool to the work surface. Lift the tool from the work surface before turning

the tool off.

Hold the planer in the correct position with one hand on the front handle and the other

on the auxiliary handle, as shown in Figure 7.

CORRECT

INCORRECT INCORRECT

FIG. 7

Place the front of the shoe on the surface to be planed, making certain that the

cutting blades are not touching the surface. Push down firmly on the front handle of

the planer so that the front shoe is ABSOLUTELY FLAT on the work surface. Turn the

tool on and allow the motor to reach full speed before touching the planer blades to

the work surface.

Move the tool slowly into the work and maintain downward pressure to keep the

planer flat. Be particularly careful to keep the tool flat at the beginning and the end of

the work surface.

Planing Tip: For a smoother appearance, fasten a piece of scrap wood to the end of

the piece you are planing. Don’t stop planing until the cutting blades of the planer are

past your work piece and into the scrap material.

Parking Foot (Fig. 1)

Your planer is equipped with a parking foot (K) that automatically lowers into place

when the tool is lifted from the work surface. When planing, the parking foot raises as

the tool is pushed forward. When the parking foot is lowered, the planer can set on

the work surface without the blade touching.

CAUTION: Do not lock the trigger switch on and engage the parking foot. The

vibration of the running motor will cause the planer to move, possibly falling from the

work piece.

MAINTENANCE

WARNING: To reduce the risk of serious personal injury, turn tool off and

disconnect tool from power source before making any adjustments or removing/

installing attachments or accessories. An accidental start-up can cause injury.

Lubrication

Your power tool requires no additional lubrication.

Cleaning

WARNING: Blow dirt and dust out of all air vents with clean, dry air at least once

a week. To minimize the risk of eye injury, always wear AS/NZS1337 approved eye

protection when performing this.

WARNING: Never use solvents or other harsh chemicals for cleaning the

non-metallic parts of the tool. These chemicals may weaken the plastic materials

used in these parts. Use a cloth dampened only with water and mild soap. Never let

any liquid get inside the tool; never immerse any part of the tool into a liquid.