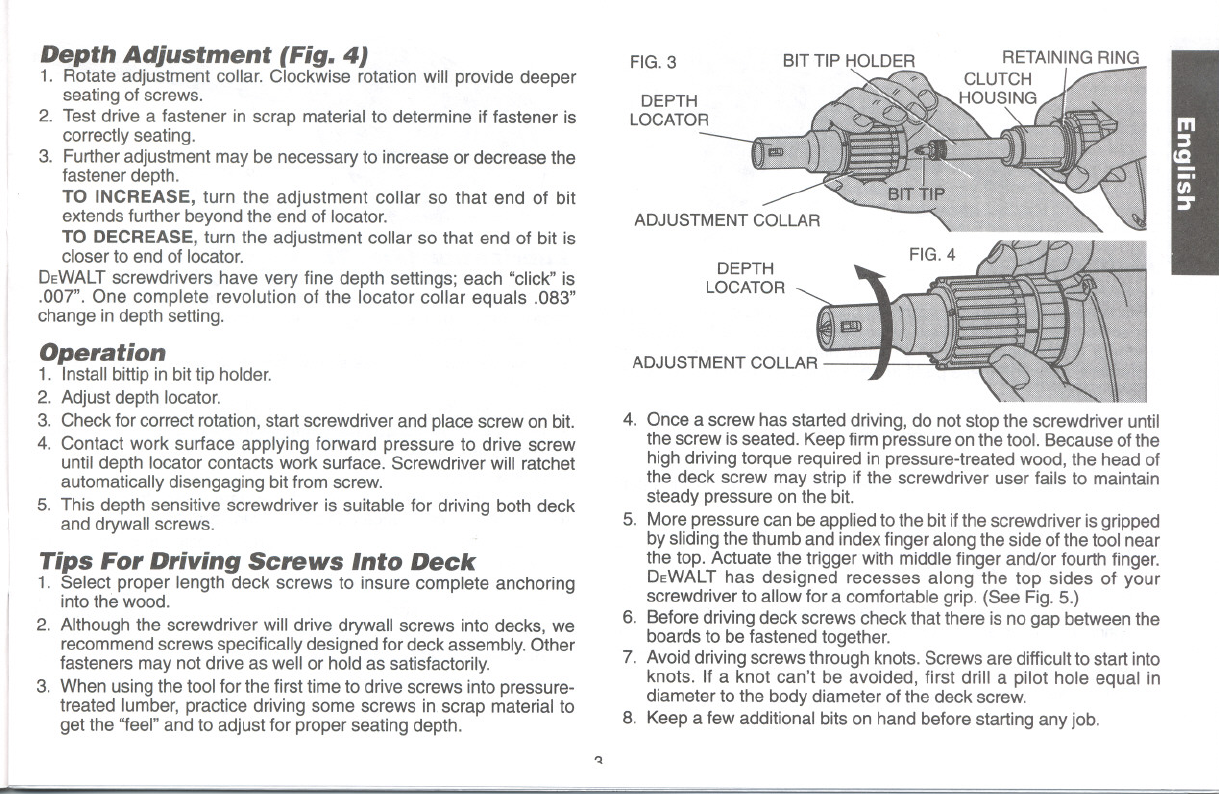

Depth Adjustment (Fig. 4J

1. Rotate adjustment collar. Clockwise rotation will provide deeper

seating of screws.

2. Test drive a fastener in scrap material to determine if fastener is

correctly seating.

3. Further adjustment may be necessary to increase or decrease the

fastener depth.

TO INCREASE, turn the adjustment collar so that end of bit

extends further beyond the end of locator.

TO DECREASE, turn the adjustment collar so that end of bit is

closer to end of locator.

DEWALT screwdrivers have very fine depth settings; each "click" is

.007". One complete revolution of the locator collar equals .083"

change in depth setting.

Operation

1. Install bittip in bit tip holder.

2. Adjust depth locator.

3. Check for correct rotation, start screwdriver and place screw on bit.

4. Contact work surface applying forward pressure to drive screw

until depth locator contacts work surface. Screwdriver will ratchet

automatically disengaging bit from screw.

5. This depth sensitive screwdriver is suitable for driving both deck

and drywall screws.

Tips For Driving Screws Into Deck

1. Select proper length deck screws to insure complete anchoring

into the wood.

2. Although the screwdriver will drive drywall screws into decks, we

recommend screws specifically designed for deck assembly. Other

fasteners may not drive as well or hold as satisfactorily.

3. When using the tool for the first time to drive screws into pressure-

treated lumber, practice driving some screws in scrap material to

get the "feel" and to adjust for proper seating depth.

FIG.3

DEPTH

LOCATOR

DEPTH

LOCATOR

4. Once a screw has started driving, do not stop the screwdriver until

the screw is seated. Keep firm pressure on the tool. Because of the

high driving torque required in pressure-treated wood, the head of

the deck screw may strip if the screwdriver user fails to maintain

steady pressure on the bit.

5. More pressure can be applied to the bit if the screwdriver is gripped

by sliding the thumb and index finger along the side of the tool near

the top. Actuate the trigger with middle finger and/or fourth finger.

DEWALT has designed recesses along the top sides of your

screwdriver to allow for a comfortable grip. (See Fig. 5.)

6. Before driving deck screws check that there is no gap between the

boards to be fastened together.

7. Avoid driving screws through knots. Screws are difficult to start into

knots. If a knot can't be avoided, first drill a pilot hole equal in

diameter to the body diameter of the deck screw.

8. Keep a few additional bits on hand before starting any job.

~