Extension Cords

If an extension cord must be used, be sure it is:

accept the plug on the product

NOTICE: RiskofPropertyDamage.Theuseofanundersizedextensioncordwillcausevoltage

todropresultinginpowerlosstothemotorandoverheating.Insteadofusinganextensioncord,

increasetheworkingreachoftheairhosebyattachinganotherlengthofhosetoitsend.Attach

additional lengths of hose as needed.

Voltage and Circuit Protection

Refer to the Specification Chart for the voltage and minimum branch circuit requirements.

WARNING: Riskof Overheating. Certain air compressors can be operated on a 15 amp

circuit if the following conditions are met.

1. Voltage supply to circuit must comply with the National Electrical Code.

2. Circuit is not used to supply any other electrical needs.

NOTE: If compressor is connected to a circuit protected by fuses, use only time delay fuses.

If any of the above conditions cannot be met, or if operation of the compressor repeatedly

causes interruption of the power, it may be necessary to operate it from a 20 amp circuit. It is

not necessary to change the cord set.

OPERATION

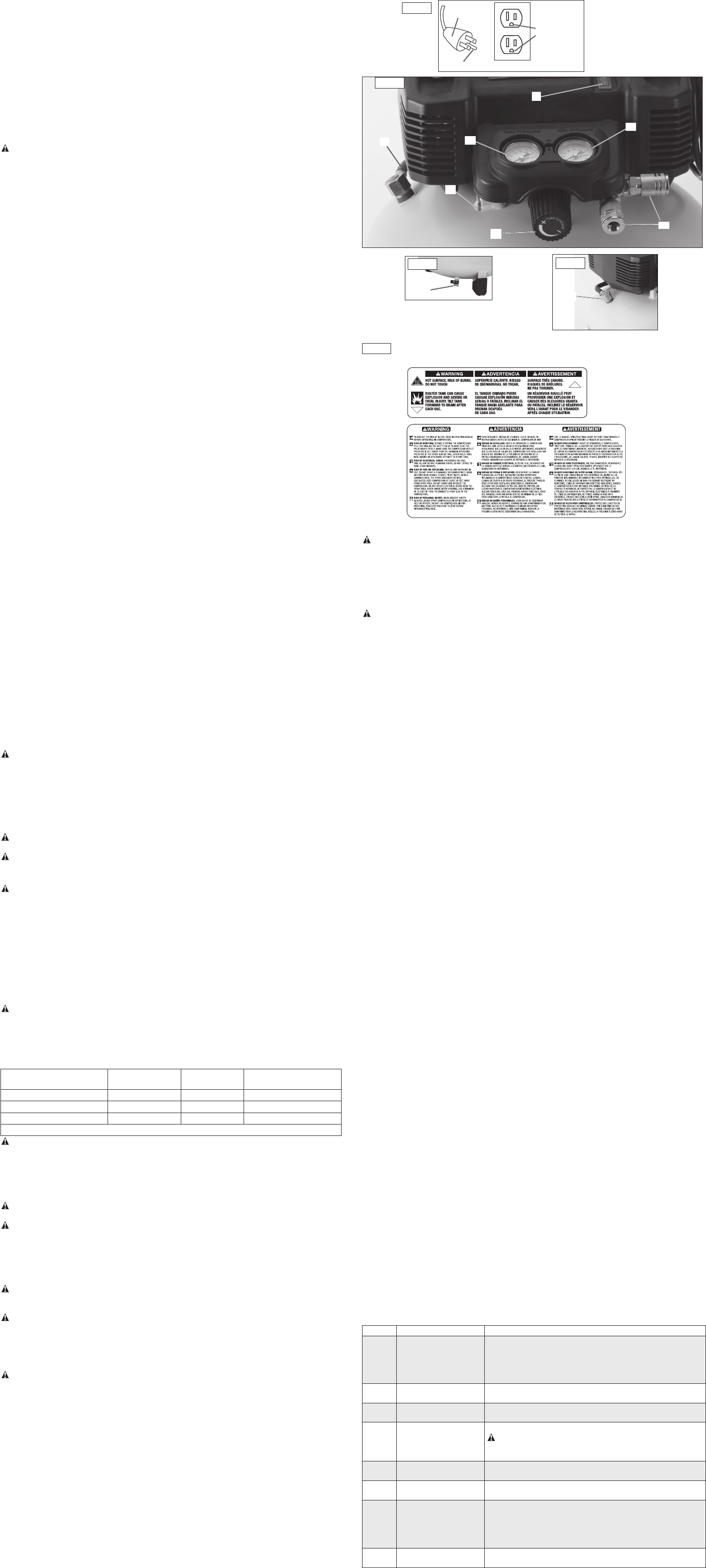

Know Your Air Compressor

Compare the illustrations with your unit to familiarize yourself with the location of various controls

and adjustments. Save this manual for future reference.

Description of Operation (Fig. 2–4)

On(I)/Off(O) Switch (D):

Pressure Switch (not shown): The pressure switch automatically starts the motor when the

Safety Valve (H):

Tank Pressure Gauge (I): The tank pressure gauge indicates the reserve air pressure in the

tank.

Outlet Pressure Gauge (E): The outlet pressure gauge indicates the air pressure available at

the outlet side of the regulator. This pressure is controlled by the regulator and is always less

than or equal to the tank pressure.

Regulator (G): Controls the air pressure shown on the outlet pressure gauge. Turn regulator

knob clockwise to increase pressure and counterclockwise to decrease pressure.

Cooling System (not shown): This compressor contains an advanced design cooling system.

At the heart of this cooling system is an engineered fan. It is perfectly normal for this fan to blow

air through the vent holes in large amounts. You know that the cooling system is working when

air is being expelled.

Air Compressor Pump (not shown): Compresses air into the air tank. Working air is not

available until the compressor has raised the air tank pressure above that required at the air

outlet.

Drain Valve (K): The drain valve is located at the base of the air tank and is used to drain

condensation at the end of each use.

Check Valve (M):

Motor Overload Protector (not shown): The motor has a thermal overload protector. If the

motor overheats for any reason, the overload protector will shut off the motor. The motor must

be allowed to cool down before restarting. To restart:

2. Allow the motor to cool.

Quick-Connect Body (F): The quick connect body accepts industrial quick connect plugs. The

two quick connect bodies allow the use of two tools at the same time.

How to Use Your Unit (Fig. 2)

HOW TO STOP

2. Unplug unit when not in use.

BEFORE STARTING

WARNING: Do not operate this unit until you read this instruction manual for safety, operation

and maintenance instructions.

BEFORE EACH START-UP

2.

Plug the power cord into the correct branch circuit receptacle.

Voltage and Circuit

Protection paragraph in the Installation

4. Attach hose and accessories.

WARNING: Risk of unsafe operation. Firmly grasp air hose in hand when installing

or disconnecting to prevent hose whip.

WARNING: Risk of unsafe operation. Do not use damaged or worn accessories.

NOTE: The hose or accessory will require a quick connect plug if the air outlet is equipped with

WARNING: Risk of Bursting. Toomuchairpressurecausesahazardousriskofbursting.

Check the manufacturer’s maximum pressure rating for air tools and accessories. The regulator

outlet pressure must never exceed the maximum pressure rating.

NOTICE: Risk of property damage. Compressed air from the unit may contain water

condensation and oil mist. Do not spray un fil tered air at an item that could be damaged by

moisture.Someairtoolsandaccessoriesmayrequirefilteredair.Readtheinstructionsforthe

air tools and accessories.

HOW TO START

reached.

WARNING: Risk of unsafe operation. If any unusual noise or vibration is noticed,

stop the compressor immediately and have it checked by a trained service technician.

The compressor is ready for use.

MAINTENANCE

Customer Responsibilities

Before each use Daily or after

each use

See tank warning label

Check Safety Valve X

Drain Tank X

Remove tank from service X

1

1- For more information,

call 1-800-4-DeW

WARNING: Risk of unsafe operation. Unit cycles automatically when power is on.

When performing maintenance, you may be exposed to voltage sources, compressed air,

or moving parts. Personal injuries can occur. Before performing any maintenance or repair,

disconnect power source from the compressor and bleed off all air pressure.

NOTE: See Operation section for the location of controls.

To Check Safety Valve (Fig. 2)

WARNING: RiskofBursting.Ifthesafetyvalvedoesnotworkproperly,over-pressurization

may occur, causing air tank rupture or an explosion.

WARNING: Risk from Flying Objects. Always wear certified safety equipment:

ANSIZ87.1eyeprotection(CAN/CSAZ94.3)withsideshields.

operates freely. If the valve is stuck or does not operate smoothly, it must be replaced with the

same type of valve.

To Drain Tank (Fig. 2, 3)

WARNING:RiskofUnsafeOperation.Airtankscontainhighpressureair.Keepfaceand

otherbodypartsawayfromoutletofdrain.UseANSIZ87.1eyeprotection(CAN/CSAZ94.3)

when draining as debris can be kicked up into face.

WARNING:Riskfromnoise.Alwayswearproperhearingprotectionduringuse.Undersome

conditions and duration of use, noise from this product may contribute to hearing loss.

NOTE:

may be regulated and must be disposed of in accordance with local, state, and federal laws and

regulations.

WARNING:RiskofBursting.Waterwillcondenseintheairtank.Ifnotdrained,waterwill

corrode and weaken the air tank causing a risk of air tank rupture.

NOTICE: RiskofPropertyDamage.Drainwaterfromairtankmaycontainoilandrustwhich

can cause stains.

4. Place a suitable container under the drain valve to catch discharge.

approximately 20 psi. Release safety valve ring.

7. After the water has been drained, close the drain valve. The air compressor can now be

stored.

NOTE: If drain valve is plugged, release all air pressure. The valve can then be removed,

cleaned, the reinstalled.

STORAGE

1. Review the Maintenance section on the preceding pages and perform scheduled

maintenance as necessary.

2. Drain water from air tank. See To Drain Tank under Maintenance.

WARNING: Water will condense in the air tank. If not drained, water will corrode and

weaken the air tank causing a risk of air tank rupture.

Wind air hose loosely around the compressor handle. Wrap electrical cord onto the cord

wrap.

4. Store the air compressor in a clean and dry location.

Accessories

WARNING: The use of any other accessory not recommended for use with this tool could be

hazardous.Useonlyaccessoriesratedequaltoorhigherthantheratingoftheaircompressor.

Recommended accessories for use with your tool are available for purchase from your local

dealer or authorized service center. If you need assistance in locating any accessory for your tool,

please contact D

e

WALT

1-800-4-D

e

WALT

Service Information

Please have the following information available for all service calls:

Repairs

performed by a D

e

WALT factory service center, a D

e

WALT authorized service center or other

qualified service personnel. Always use identical replacement parts.

Full One Year Warranty

DeW heavy duty industrial tools are warranted for one year from date of purchase. We

will repair, without charge, any defects due to faulty materials or workmanship. For warranty

repair information, call 1-800-4-D

e

WALT

accessories or damage caused where repairs have been made or attempted by others. This

warranty gives you specific legal rights and you may have other rights which vary in certain states

or provinces.

LATIN AMERICA:

packaging, call the local company or see website for warranty information.

FREE WARNING LABEL REPLACEMENT (Fig. 5): If your warning labels become illegible or

are missing, call 1-800-4-D

e

WALT

GLOSSARY

CFM: Cubic feet per minute.

SCFM:

PSI:

kPa (kilopascal):

Code Certification:

®

®

and meet the applicable Standards for Safety.

*UL

®

is a registered trademark of Underwriters Laboratories and ETL

®

is a registered

trademark of Electrical Testing Laboratories.

Cut-In Pressure: While the motor is off, air tank pressure drops when accessory is used.

When the tank pressure drops to a certain low level the motor will restart automatically. The

low pressure at which the motor automatically restarts is called cut-in pressure.

Cut-Out Pressure: When an air compressor is turned on and begins to run, air pressure in

the air tank begins to build. It builds to a certain high pressure before the motor automatically

shuts off, protecting your air tank from pressure higher than its capacity. The high pressure at

which the motor shuts off is called cut-out pressure.

Branch Circuit: The circuit carrying electricity from electrical panel to outlet.

Duty Cycle: This air compressor pump is capable of running continuously. However, to prolong

given hour.

Troubleshooting Guide

This section provides a list of the more frequently encountered malfunctions, their causes and

corrective actions. The operator or maintenance personnel can perform some corrective actions,

and others may require the assistance of a qualified D

eW technician or your dealer.

Problem Code

Excessive air tank pressure-safety valve pops off ................................................... 1, 2

Air leaks ....................................................................................................................

Air leaks in air tank or at air tank welds ...................................................................... 4

Air leaks between head and valve plate .....................................................................

Air leaks from safety valve .......................................................................................... 6

Pressure reading on the regulated pressure gauge

drops when an accessory is used .............................................................................. 7

Compressor is not supplying enough air to operate accessories

............................................................................................................

Regulator knob has continuous air leak ...................................................................

Regulator will not shut off air outlet ..........................................................................

.............................................................

Squealing Sound ..................................................................................................... 21

Troubleshooting Codes

CODE POSSIBLE CAUSE POSSIBLE SOLUTION

1 Pressure switch does

not shut off motor

when compressor

reaches cut-out

pressure

Set the Auto/Off switch to OFF, if the unit does not shut

off contact a D

e

e

authorized service center.

2 Pressure switch cut-

out too high

Contact a D

e

e

authorized service center.

Tube fittings are not

tight enough

Tighten fittings where air can be heard escaping. Check

fittings with soapy water solution. Do Not Overtighten.

4 Defective air tank Air tank must be replaced. Do not repair the leak.

WARNING:Riskofbursting.Donotdrillinto,weldor

otherwise modify air tank or it will weaken. The air tank can

rupture or explode.

Contact a D

e

e

authorized service center.

6 Defective safety valve Operate safety valve manually by pulling on ring. If valve still

leaks, it must be replaced.

7 Regulator is not

adjusted correctly for

accessory being used

It is normal for some pressure drop to occur when an

accessory is used, adjust the regulator as instructed in

Regulator under Features if pressure drop is excessive.

NOTE: Adjust the regulated pressure under flow conditions

while accessory is being used.

8 Prolonged excessive

use of air

Decrease amount of air usage.

FIG. 5

C

A

B

FIG. 1

FIG. 3

FIG. 4

FIG. 2

D

H

I

E

F

J