19

Fig. 38

1. NOTE: One 7/8" wrench is supplied with the saw for

changing the saw blade.

2. Remove table insert (A) Fig. 38, and raise saw blade

(F) to its maximum height.

3. To remove blade, place the wrench (D) on the flats of

the arbor nut (C) to keep the arbor from turning. Place a

piece of wood (B) flat on the table against the blade so

that a tooth of the blade can “grab” the wood to keep

the blade from turning. Use wrench to turn the arbor nut

toward the front of the saw. Remove arbor nut, blade

flange (E), and saw blade.

4. Assemble the new blade, making certain the teeth

point down at the front of the saw table, and assemble

outside blade flange and arbor nut. Using the piece of

wood (B) to keep the blade from turning, tighten arbor

nut by turning wrench (D) toward the rear of the saw.

5. Replace table insert.

F

C

E

D

B

A

CHANGING THE BLADE

DISCONNECT THE MACHINE FROM THE POWER SOURCE. USE ONLY 10" DIAMETER SAW BLADES

RATED FOR 4700 RPM OR HIGHER. USE ONLY SAW BLADES WITH 5/8" ARBOR HOLES.

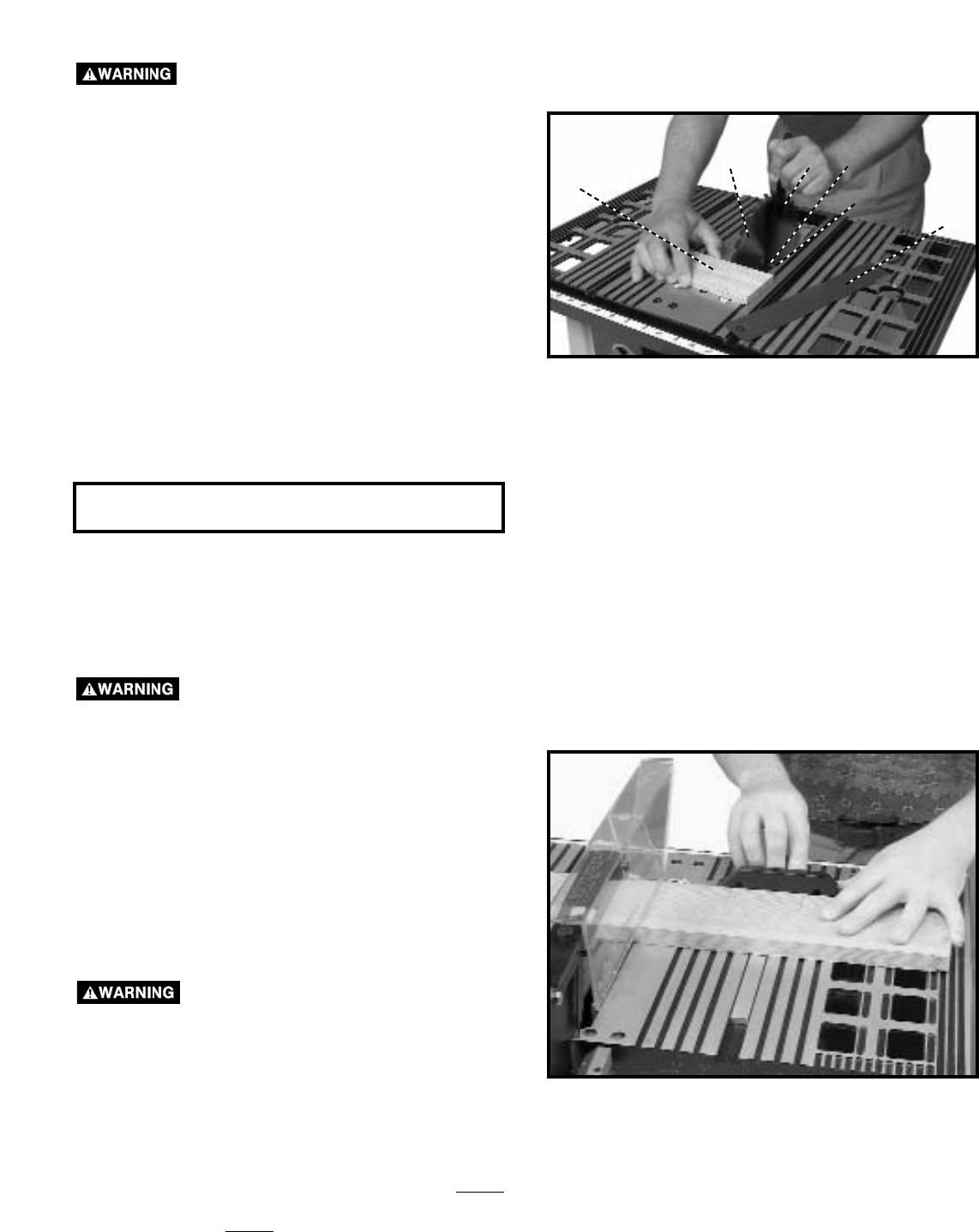

CROSS-CUTTING

Cross-cutting requires the use of the miter gage to

position and guide the work. Place the work against the

miter gage and advance both the gage and work toward

the saw blade, as shown in Fig. 39. The miter gage may

be used in either table slot. When bevel cutting (blade

tilted), use the table groove that does not cause

interference of your hand or miter gage with the saw

blade guard.

Start the cut slowly and hold the work firmly against the

miter gage and the table.

ONE OF THE RULES IN RUNNING A

SAW IS THAT YOU NEVER HANG

ONTO OR TOUCH THE PART OF THE WORKPIECE

THAT WILL BE CUT OFF.

Hold the supported piece, not the free piece that is cut

off. The feed in cross-cutting continues until the work is

cut in two, and the miter gage and work are pulled back

to the starting point. Before pulling the work back, it is

good practice to give the work a little sideways shift to

move the work slightly away from the saw blade. Never

pick up any short length of free work from the table while

the saw is running. Never

touch a cut-off piece unless it

is at least a foot long.

Common sawing operations include ripping and crosscutting plus a few other standard operations of a fundamental

nature. As with all power machines, there is a certain amount of hazard involved with the operation and use of the

machine. Using the machine with the respect and caution demanded as far as safety precautions are concerned, will

considerably lessen the possibility of personal injury. However, if normal safety precautions are overlooked or completely

ignored, personal injury to the operator can result. The following information describes the safe and proper method for

performing the most common sawing operations.

THE USE OF ATTACHMENTS AND ACCESSORIES NOT RECOMMENDED BY DELTA MAY RESULT

IN THE RISK OF INJURY TO THE USER OR OTHERS.

Fig. 39

MACHINE USE

For added safety and convenience the miter gage (A)

can be fitted with an auxiliary wood-facing (B), as shown

in Fig. 39A, that should be at least 1 inch higher than the

maximum depth of cut, and should extend out 12 inches

or more to one side or the other depending on which

miter gage slot is being used. This auxiliary wood-facing