19

4.1 Switch/Overload Protection

The switch is equipped with a no-volt release solenoid (magnetic switch), to

prevent start-up after a power failure. If the saw is not connected to the power

mains the switch does not engage. In the event of a power failure the machine

has to be restarted. In case of an overload of the main motor the build-in motor

protection relay trips and cuts the power to the motor. If the motor is shut off

repeatedly by the overload relay, check machine (motor brake action, dull blade,

low voltage etc.). A cooling down period of 30 min. is recommended.

A light humming from the solenoid inside the switch is normal and does not

indicate a fault.

- Block rotary switch knob with a padlock to prevent unauthorized use.

5 Controls/Settings

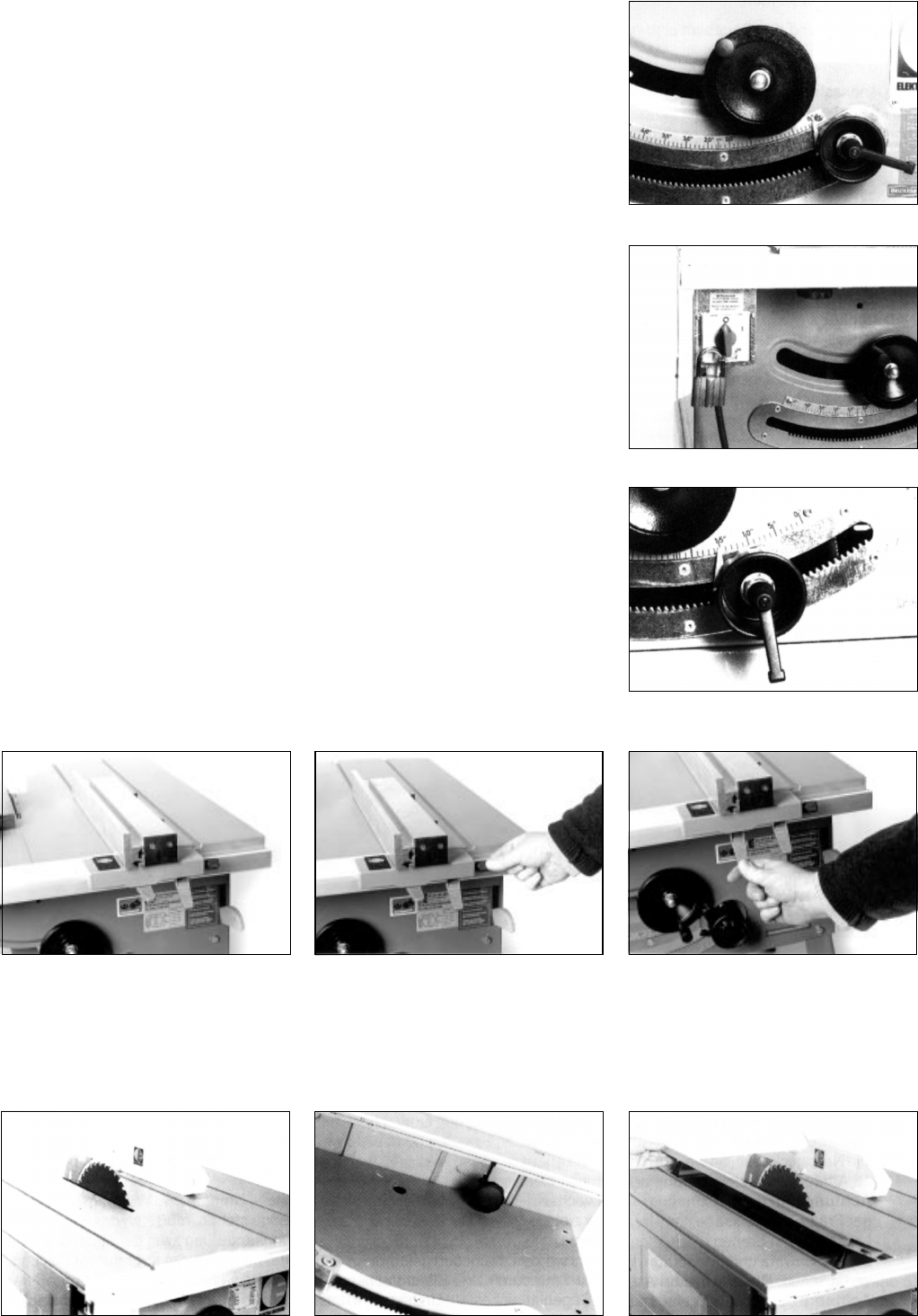

5.1 Sawblade Vertical Setting

The depth of cut of the main blade is set by turning the cranked handwheel.

Turn clockwise to raise blade

Turn counter-clockwise to lower blade

To compensate for possible play always raise blade into desired position.

5.2 Blade Tilt

After release of the ratchet lock lever inside the handwheel the blade can be tilted

steplessly to any position between 90° and 45° by turning the handwheel.

Reference point is the graduation mark to the right of the pointer.

- Tighten ratched lock lever after setting.

Caution! Carry out setting only with the blade at complete standstill.

5.4 Opening the Chipcase

Disconnect from power before servicing!

Loosen wingnut of saw blade guard a few

turns. Pull forward and up to remove blade

guard from riving knife.

Loosen starknobs located below the table

at front and rear of removable table sec-

tion and push against the workstand panel.

Remove the removable table section.

5.3 Rip Fence Setting

Place rip tence onto the saw table. Set to

required width of cut, then push the right

hand side lock lever down.

Turn micro-adjuster screw to set fence to

exact dimension.

After micro-adjustment is made push down

the left hand side lock lever to lock the rip

fence in position.