This machine or any of its parts should not be altered or changed from standard specifications. The user of this

machine shall have the sole responsibility for any malfunction which results from improper use or unauthorized

modification from standard specifications, faulty maintenance, damage or improper repair by anyone other than

qualified persons approved by metabo or its representatives.

M

etabo reserves the right to change specifications and design without prior notice and without incurring

obligation of any kind.

Equipment referred to as available or optional may be at extra cost.

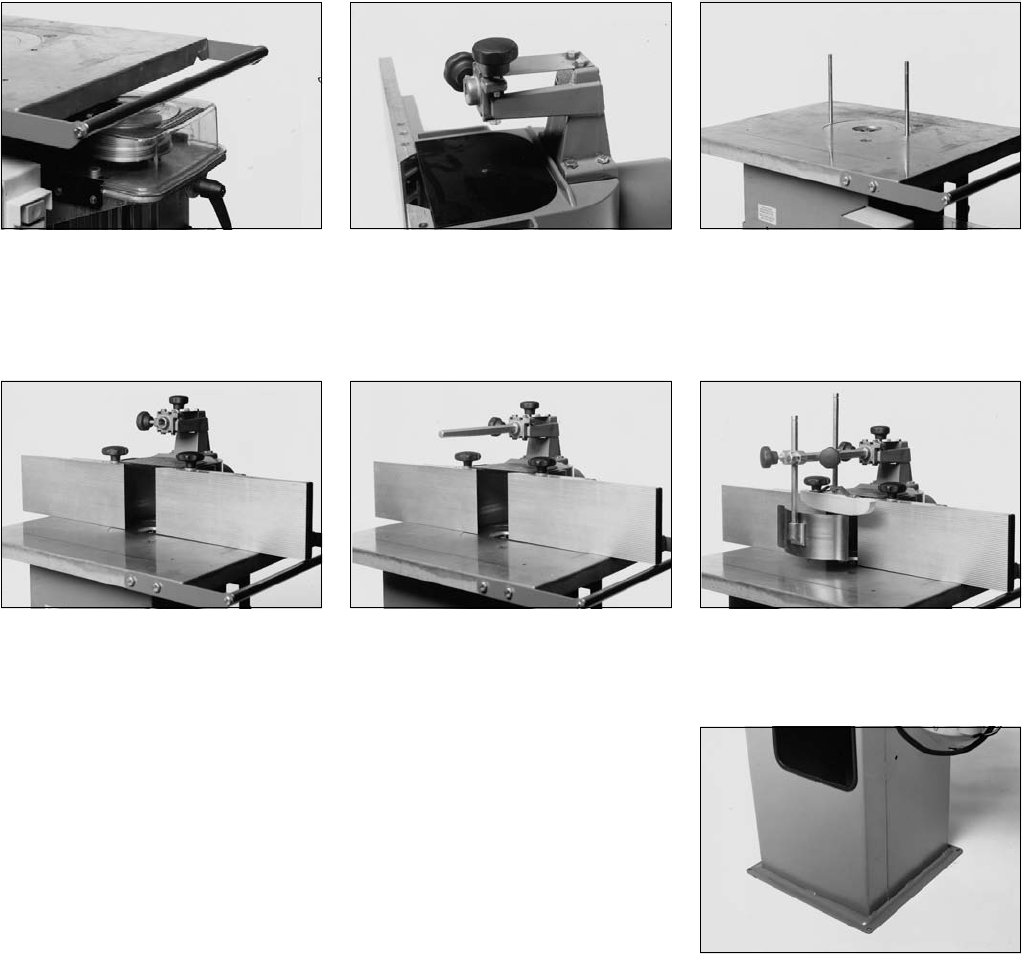

3 Standard Accessories

Spacing collars: 1 pc. 25 mm, 1 pc. 16 mm,

2 pcs. 10 mm, 2 pcs. 8 mm,

2 pcs. 5 mm

Spindle nut: M 30x2

Fence

Fence plates

SUVA style safety cutter guard

Tool set

Instructions

6 Installation

Important!

This spindle moulder model TF 100 M must be anchored to the floor for

stability. A machine not anchored to the floor may fall over while in

operation.

Use suitable means for anchoring, e.g. anchoring bolts or expansion

anchors Ø 8 mm.

Place fence on table and screw

starknobs onto stud bolts.

Slide hexagon bar into fence carrier

and lock with starknob screw.

Install holddown shoe and spring on

hexagon bar.

5 Final Assembly

Set table extension level with the table. Install cutter guard carrier on the fence.

Use 4 each

- hexagon head screw M 6x25

- hex. nut M 6 self-locking

Screw both stud bolts into the tapped

bore holes of the table.

4 Optional Accessories

Table Extension TF 100 Stock-no. 0914003598

Sliding Carriage TF 100 Stock-no. 0914015600

Moulding Tools see separate catalogue