17 2008SSD-34 (5/11) 16 2008SSD-34 (5/11)

Single-Compressor Module Operation

4.0 maiNteNaNCe

4.1 Routine Maintenance

Perform the maintenance procedures in Table 5 at least once per year or more often if needed.

Oil consumption varies by application and during initial operation. Monitor the oil level routinely to

determine a consistent pattern of actual consumption.

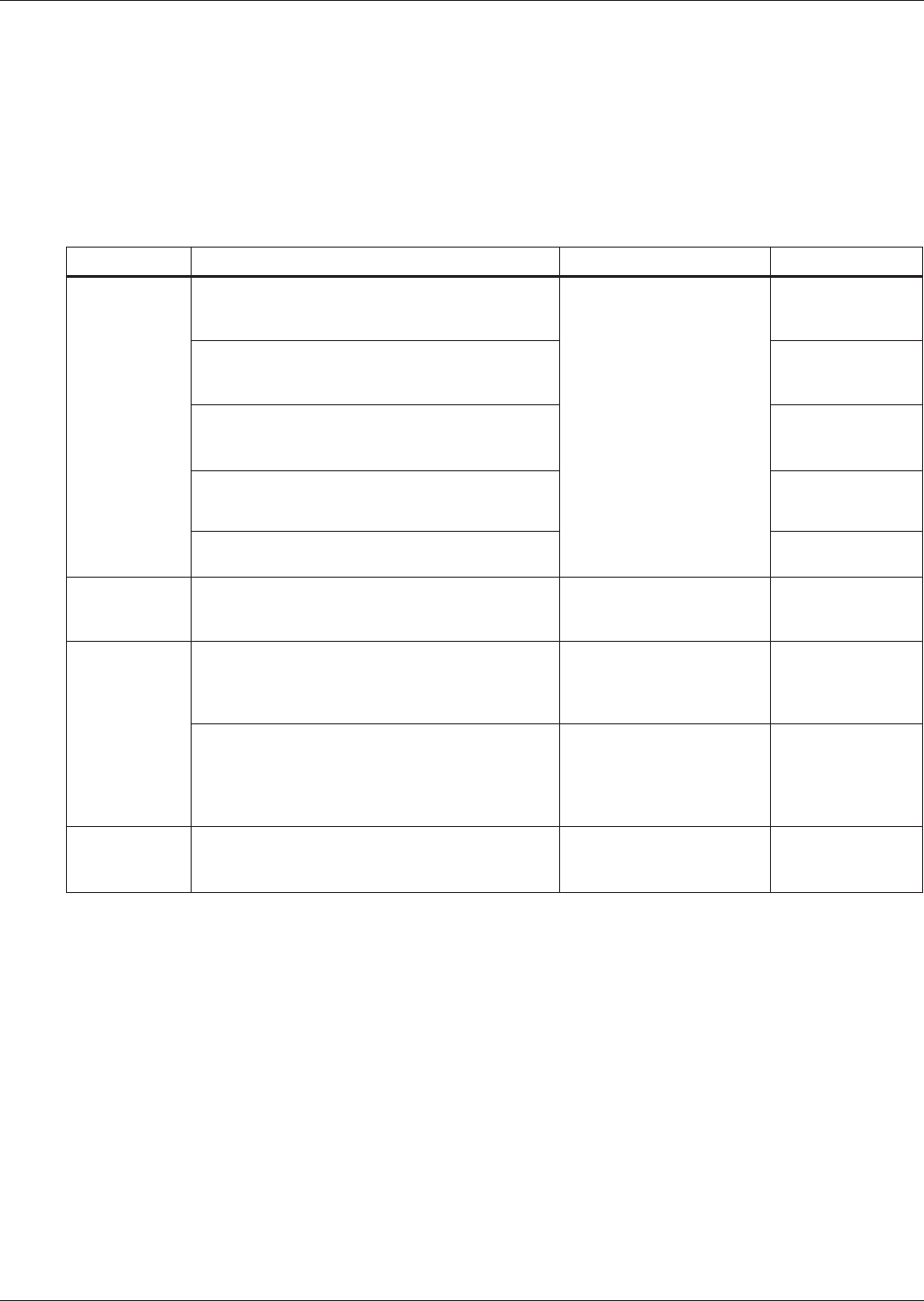

Table 3 Maintenance summary

Components Maintenance Reason For details, see:

Lubrication

& Cooling

System

• Monitor and check the oil level.

A low oil level or loss

of oil in the system will

result in overheating or

mechanical failure.

A high oil level may result

in excessive oil carryover

and oil discharge from

the Compressor Module

when the Compressors

are turned off.

4.3 - Oil Sevice

(page 19)

• Add oil as needed.

4.3 - Oil Service

(page 19)

• Change oil annually.

Note: Some applications may require more

frequent service.

4.3 - Oil Service

(page 19)

• Check the condition of the lubricant

periodically. Normal color is clear or light

gray.

—

• Change the oil lter (if equipped) annually

or as required.

—

Gas Inlet

System

• Inspect and clean the inlet screen annually

or more often as needed.

A restricted inlet screen

will result in reduced ow.

4.6 - Cleaning

the Inlet Screen

(page 21)

Second-

Stage

Separator

System

• Inspect and clean the scavenge line orice

annually or more often as needed.

A restricted scavenge

line orice will result in

excessive oil carryover.

4.7 - Servicing

the Scavenge

Line Orice

(page 21)

• Change the second-stage oil separator

element annually or more often if

contaminated.

Note: Some applications may require more

frequent service.

A dirty or plugged

separator element will

result in excessive oil

carryover.

4.8 - Changing

the Second-

Stage Separator

Element

(page 24)

Oil Heat

Exchanger

• Ensure heat exchanger cooling ns are clear

of dust and debris.

• Verify that the fans run freely.

— —

See 5.0 - Troubleshooting on page 22 for additional details.