21 2008SSD-34 (5/11) 20 2008SSD-34 (5/11)

Single-Compressor Module Maintenance

4.4 Cleaning the Inlet Screen

The 30-mesh screen in the inlet block must remain unobstructed for optimal ow rate. If the ow rate is

lower than expected even when the Compressor is running properly, this screen may be obstructed.

Figure 14 Gas Inlet Block and Screen

To inspect and clean the inlet screen:

1. Turn off and isolate the Compressor from all power

sources.

2. Turn off the gas supply.

3. Vent the system to 0 psig.

4. Remove the SAE plug on the side of the inlet block.

5. Remove the screen.

6. Inspect the screen and inside of the block. Clean or

replace if necessary.

7. Replace SAE nut.

8. Return the Compressor Package to service.

9. Check for leaks at all ttings that have been disturbed.

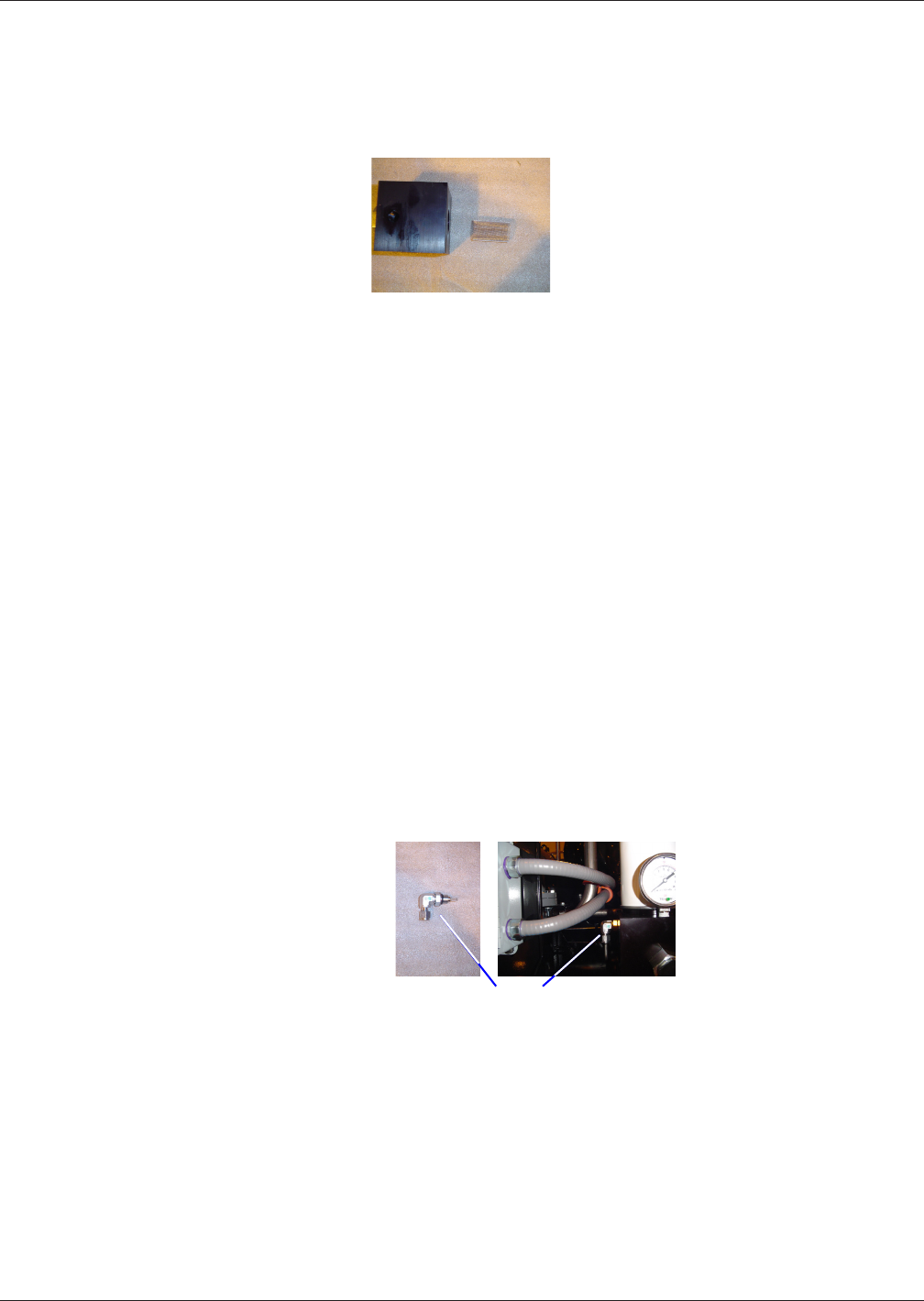

4.5 Servicing the Scavenge Line Orice

The scavenge line orice in the oil separator block must remain clear of obstruction. If this orice is

restricted, the secondstage oil separator can become saturated, increasing oil consumption.

Note: image shown is 90 degree orice. Procedure is the same for straight orice.

Figure 15 Scavenge Line Orice

Orifice

To inspect and clean the orice:

1. Turn off and isolate the Compressor from all power sources.

2. Turn off the gas supply.

3. Vent the system to 0 psig.

4. Disconnect the tube and remove the tting.

5. Inspect the screen. Clean or replace the tting assembly if necessary.

6. Replace the tting and reconnect the tube. Tighten the swage nut hand tight plus 1/4 turn.

7. Return the Compressor Package to service.

8. Check for leaks at all ttings that have been disturbed.