English

13

THE DETECTOR IS GIVING OFF A TONE BUT THE

LCD DISPLAY WINDOW IS NOT FUNCTIONING.

• If the detector is very cold, allow it to warm up in a heated area.

• If the LCD display window is still not functioning, take the detec-

tor to a D

EWALT service center.

LASER MAINTENANCE

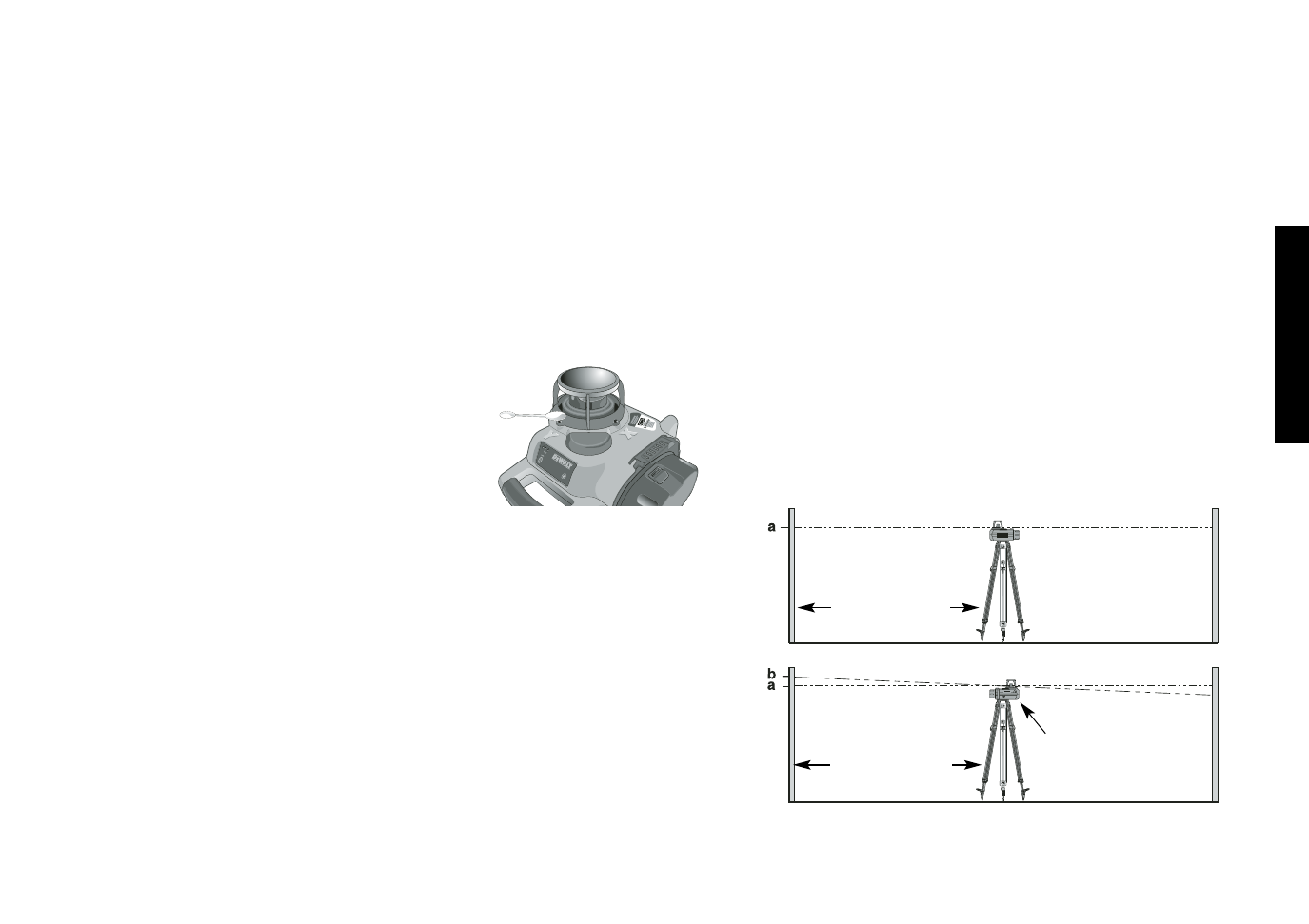

1. Under some conditions, the

glass lens inside the rotary

head may collect some dirt or

debris. This will affect beam

quality and operating range.

The lens should be cleaned

with a cotton swab moistened

with water as shown.

2. The flexible rubber shield can be cleaned with a wet lint-free

cloth such as a cotton cloth. USE WATER ONLY — DO NOT

use cleansers or solvents. Allow the unit to air dry before

storing.

3. To maintain the accuracy of your work, check the calibration of

the laser often. See the Field Calibration Check section of this

manual.

4. Calibration checks and other maintenance repairs can be

performed by D

EWALT service centers. Two free calibration

checks are included under the D

EWALT One Year Free

Service Contract.

5. When the laser is not in use, store it in the kit box provided.

6. Do not store your laser in the kit box if the laser is wet. Dry

exterior parts with a soft, dry cloth and allow the laser to air dry.

7. Do not store your laser at temperatures below 0˚F (-18˚C) or

above 105˚F (41˚C).

CLEANING

Exterior plastic parts may be cleaned with a damp cloth and mild

detergent. Although these parts are highly solvent resistant,

NEVER use solvents. Never use compressed air to clean the laser.

Field Calibration Check

Field calibration checks should be done frequently. This section

provides instructions for performing simple field calibration checks

of your D

EWALT Rotary Laser. Field calibration checks do not

calibrate the laser. That is, these checks do not correct errors in the

leveling or plumbing capability of the laser. Instead, the checks

indicate whether or not the laser is providing a correct level and

plumb line. These checks cannot take the place of professional

calibration performed by a D

EWALT service center.

LEVEL MODE CALIBRATION CHECK

1. Set up a tripod 50' (15m) from a vertical wall as shown. Make

sure that the head of the tripod is level using a bubble vial.

APPROX. 50 ft.

(15m)

APPROX. 50 ft.

(15m)

BEAM

BEAM

LASER UNIT

ROTATED 180˚