3

to the processing instructions of the material

manufacturer.

The user is liable for any damage

and injury resulting from incorrect usage!

Electrical connection and operation

The supply voltage must correspond with the

voltage figure on the voltage on the rating plate.

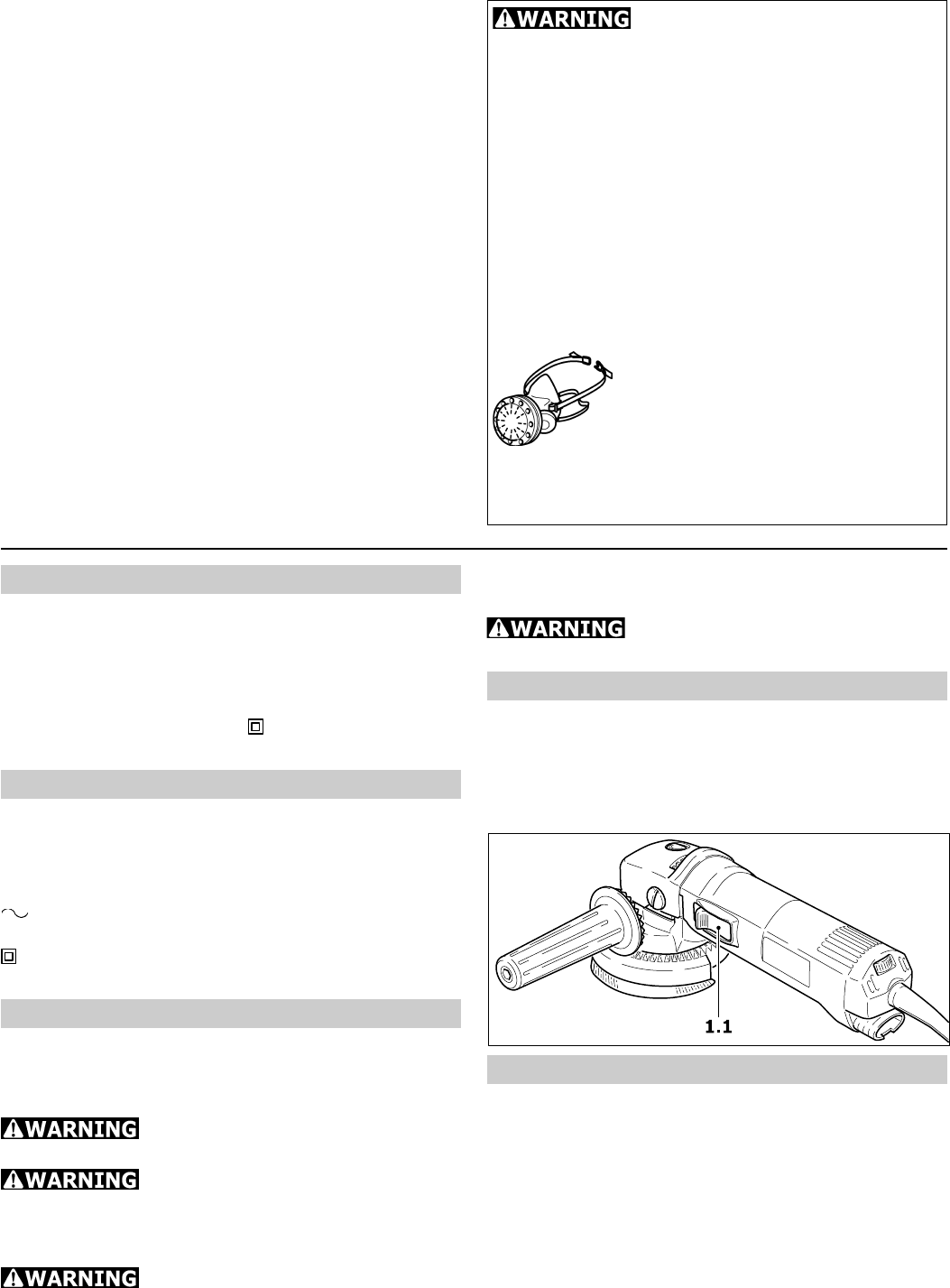

To switch the tool on, push the safety sliding

switch (1.1) forwards. The tool is switched off

by gently pressing the rear end of the switch.

Extension cord

If an extension power cord is required, it must

have sufficient cross-section to prevent an

excessive drop in voltage or overheating. An

excessive drop in voltage reduces the output

and can lead to failure of the motor. The table

shows the correct size to use, depending on

cord length and the tools ampere rating. Use

only U.L. and CSA listed extension cords. Never

use two extension cords together. Instead, use

one longer one.

Technical data RAS 115.04 E

Wattage 500 Watt

No load speed 1500 - 4000 rpm

Tool dia. up to 115 mm / 4.5"

Spindle thread M 14

Weight 1.6 kg / 3.5 lbs

Safety standard

/ II acc. to UL 745,

CSA C22.2 No. 745

Symbols

V volts

A amperes

Hz hertz

W watt

alternating current

n

0

no load speed

Class II Construction

rpm revolutions per minute

Use for intended purpose

The RAS 115.04 E is designed for sanding wood,

plastics, stone, composite materials, paints /

lacquers, fillers, stoppers and similar materials.

The tool may not be used for

grinding or cutting metal.

On the tool no grinding disks may

be fastened. It may be worked only with the

provided sanding pad and whereupon fastened

abrasives.

The device is unsuitable for wet

sanding for reasons of electrical safety.

If explosive or self-inflammable dusts are

produced when sanding certain materials, refer

Various dust created by power

sanding, sawing, grinding, drilling and other

construction activities contains chemicals

known (to the State of California) to cause

cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

lead from lead-based paints,

crystalline silica from bricks and cement and

other masonry products, and

arsenic and chromium from chemically-

treated lumber.

The risk from these exposures varies,

depending on how often you do this type of

work.

To reduce your exposure to these

chemicals: work in a well

ventilated area, and work with

approved safety equipment, such

as dust masks that are specially

designed to filter out microscopic

particles.

21 Check for misalignment or binding of

moving parts, breakage of parts, and any

other condition that may affect the tools

operation. If damaged, have the tool

serviced before using. Many accidents are

caused by poorly maintained tools.

22 Use only accessories that are

recommended by the manufacturer for

your model. Accessories that may be suitable

for one tool, may become hazardous when used

on another tool.

Service

23 Tool service must be performed only by

qualified repair personnel. Service or

maintenance performed by unqualified personnel

could result in a risk of injury.

24 When servicing a tool, use only identical

replacement parts. Follow instructions in

the Maintenance section of this manual. Use

of unauthorised parts or failure to follow

Maintenance instructions may create a risk of

electric shock or injury.