7

8. If previously disassembled thoroughly clean all exposed surfaces on the

spacer (29E) and all exposed threads on the plunger bolt (29C) and the

steel plunger base (25). Threads MUST be free of old loc-tite and any

other material such as oil, grease, etc. This is necessary to ensure proper

curing of new loc-tite. Giant recommends cleaning the threads with

acetone or other suitable cleaner. Reassemble plunger assembly parts

(29A, 29B, & 29E) using a new copper gasket (29D) and the cleaned

plunger bolt (29C). Slide the bolt through the center of the four (4) pieces

so that the threaded end is exposed. Apply several drops of loc-tite 243

(or equivalent) adhesive to the threads. Thread into steel plunger base and

tighten to 26 ft.-lbs. BE CERTAIN ALL PARTS ARE CENTERED

WITH THE BOLT!

7. Oil seal replacement can be

accomplished by pulling the

retainer forward out of the

crankcase. The o-ring around

the outside of the retainer

should be replaced and lubri-

cated with a light film of oil.

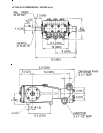

29E 29A 29B 29D 29C

LP122A-3100 - Repair Instructions

9. Lubricate weep seal (36). Place, weep seal (36), and pressure ring (36A)

into the seal sleeve (35). Assemble the o-ring (35A) onto seal sleeve and

lubricate.

10. Place support ring (41) and

v-sleeves (40) into valve

casing.

6. Inspect surface of plunger pipe (29B) carefully. Remove

any chemical or mineral deposits taking care not to damage

the surface of the plunger. If plunger pipe is worn, remove

the plunger bolt (29C) , plunger pipe (29B) and spacer

(29E). Replace worn parts necessary. Note:

Always use a

new copper gasket (29) when repairing the plunger assem-

bly.

5. If there are signs of

oil leaking through

the plunger oil seals,

then replacment is

neccessary.Remove

the plunger pipe

(29B) before inspect

ing oil seals (31A &

33). Dissassemble the

gear end and push out

the seals from the

back of the pump.

29E 29A 29B 29D 29C