14

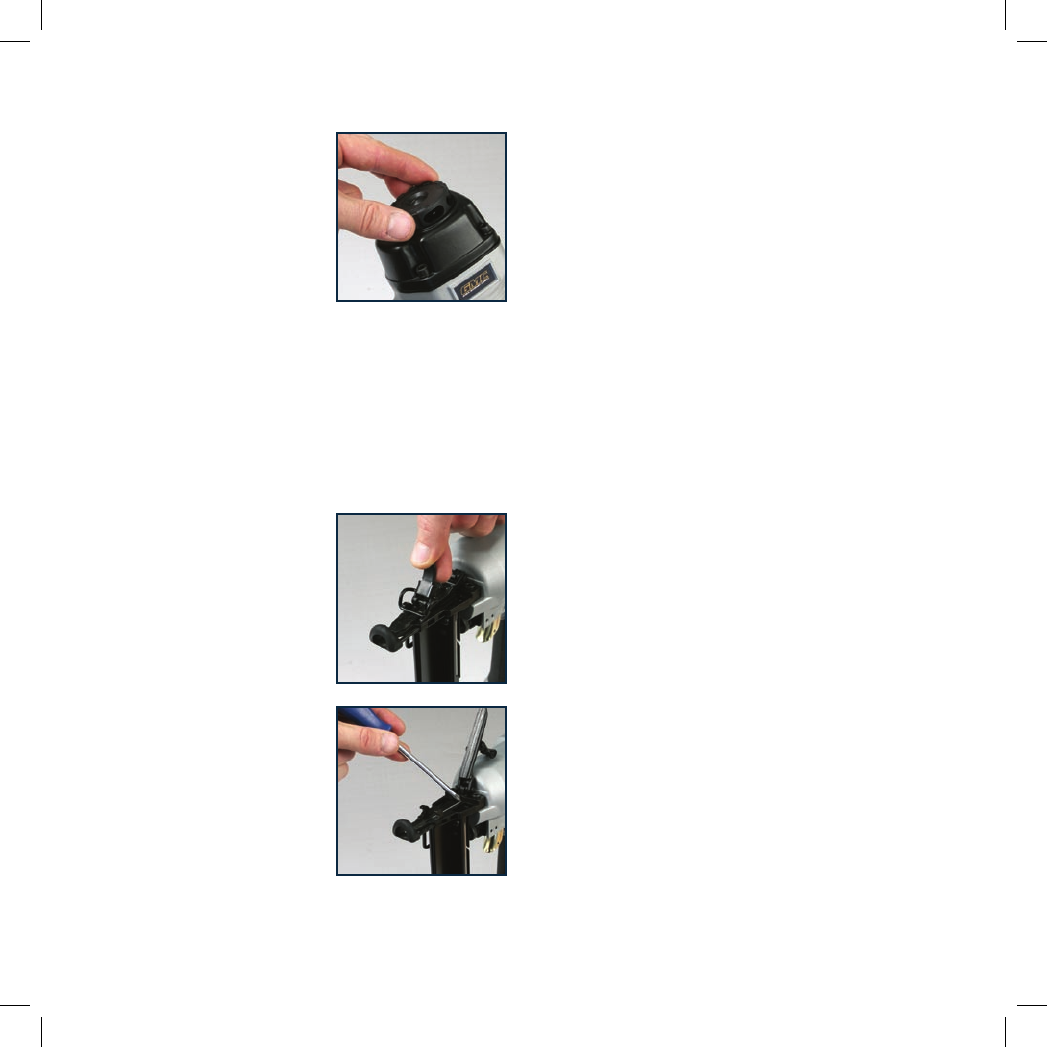

Adjusting the exhaust direction:

1. The finish nailer is equipped

with an adjustable direction

exhaust deflector (1). Simply

adjust the directional exhaust

deflector so that the exhaust

air blast will be directed away

from the operator. Grasp the

deflector and rotate it to the

desired position for the current

application.

Adjusting the fastening depth:

1. Regulate the air pressure to 120 PSI at the compressor.

2. Connect the air hose to the nailer and test for penetration

by driving fasteners into a sample piece of wood. If the

fasteners do not achieve the desired depth, rotate the

depth adjustment thumb wheel (10) until the desired

depth is achieved.

Clearing a jam:

1. Disconnect the air supply

from the nailer and remove all

fasteners from the magazine.

2. Press the quick release latch

(9) which will disengage

the driver safety cover (8).

Remove the driver safety

cover (8) so the jammed

fastener is exposed.

3. Remove the jammed fastener,

using screwdriver or long nose

pliers if required.

4. Close back the driver safety

cover tightly.

5. Test the finish nailer.

Air source

This tool is designed to operate on clean, dry, compressed

air at regulated pressures between 75 and 120 PSI.

The preferred system would include a filter, a pressure

regulator, and an automatic oiler located as close to the tool

as possible.

All compressed air contains moisture and other

contaminates that are detrimental to internal components

of the tool. An air line filter will remove most of these

contaminates and significantly prolong the life of the tool.

If an in-line oiler is not available, place 3 - 4 drops of non

detergent oil into the tool’s air inlet at the beginning of each

workday.

DANGER. All air line components (hoses, connectors,

filters, regulators, etc.) must have a minimum working

pressure rating of at least 120 PSI or 150% of maximum

system potential, whichever is greater.