11

Operation

1. The pressure in the tank is controlled by the action of

the pressure switch. When the set maximum pressure

is reached the pressure switch activates and the motor

is switched off. The pressure then decreases as the

air is used by the connected tool until the set minimum

pressure is reached after which the pressure switch

causes the motor to switch on again. The operator of

the compressor should be well aware that during use of

the compressor the motor will start and stop under the

influence of the rising or falling pressure in the tank. The

motor will start without any warning.

2. The maximum and minimum pressures are factory set

and the operator should not try to change them.

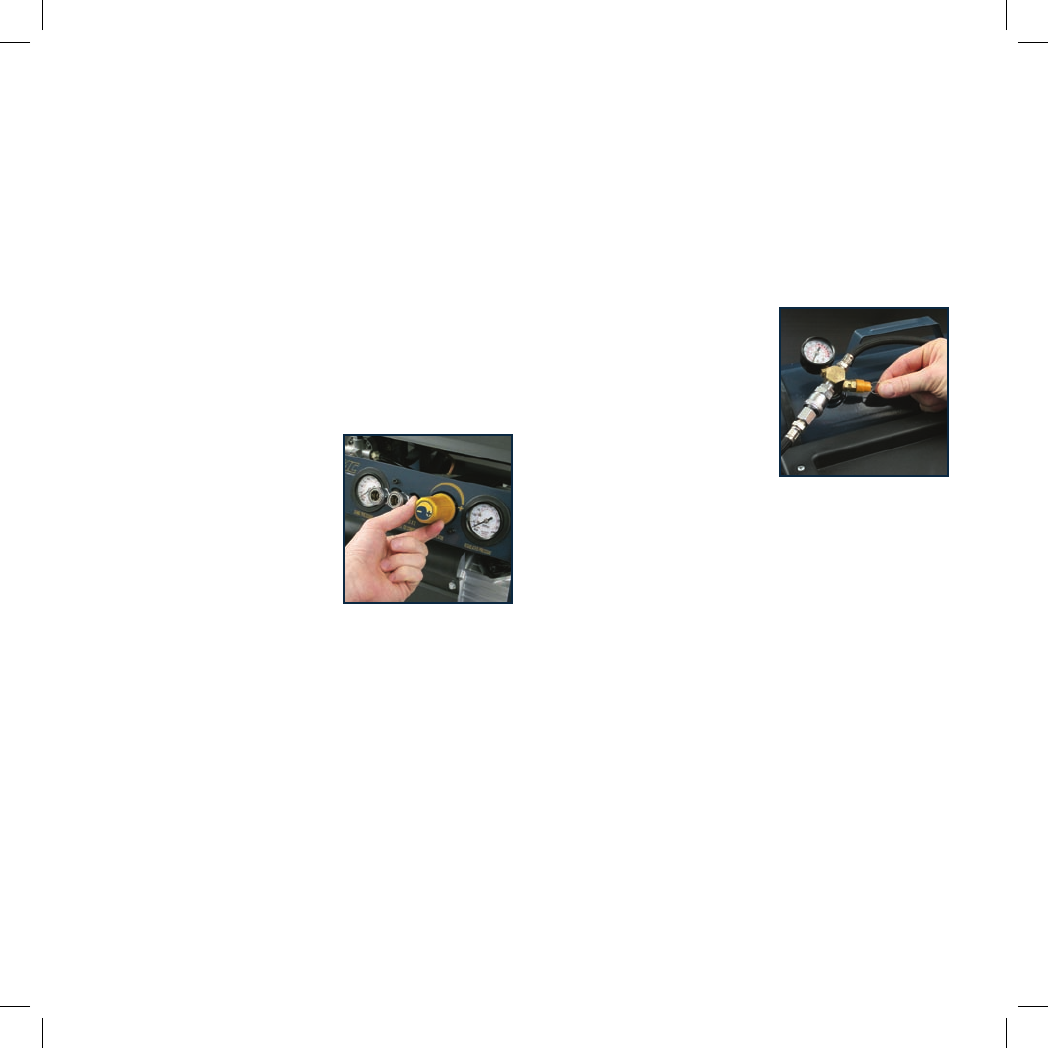

3. All accessories are connected to either the Nitto style

quick coupler regulated air

outlets (4) or the removable

tank inflator hose (27).

4. The pressure of the regulated

quick connect outlets is shown

on the regulated outlet pressure

gauge (6). The regulated

pressure can be adjusted by

turning the regulating knob (5).

Note. To obtain the correct output reading on the regulated

output gauge, the air must be flowing through the outlet(s)

(4). The regulating valve should be adjusted and the gauge

read with the outlet valve open and the air being discharged

from the regulated outlet through the accessory being

used. If you are using both of the regulated outlets (4)

simultaneously make sure that the tools being connected

have the same pressure operation requirements. To

increase the air pressure, rotate the regulating valve

clockwise. To decrease the pressure, rotate the regulating

valve anti-clockwise.

Note. If you do not allow the air to discharge while you

are setting the regulator, the pressure as indicated on the

regulated outlet gauge will be incorrect. This gauge ONLY

indicates the correct pressure while air is being discharged

from the outlet.

5. On completion of the task, i.e. when you have finished

using the compressor, or when you are leaving the

compressor unattended, turn off the compressor in the

following way:

• Lift the on/off switch (2) to the off position

• Wait for the pressurised air to bleed from the release valve.

Note. You will hear a short air discharge of approx

½ second however, this discharge only occurs if the

compressor is actually running at the time, and not in idle.

• Switch off the electrical

power supply and remove the

electrical plug.

• Pull the ring on both of the

safety valves (7) to ensure all

the pressurised air is released

from the tank, or open the both

drain cocks (9) to release the

pressure from the tank.

Tank removal/installation

This twin tank air compressor has the added benefit of a

removable tank which provides a mobile source of limited/

short term compressed air. This has many advantages

including inflating flat tyres on site as well as performing

small brad nailing tasks.

Note. It is important that end users understand the

capabilities of the removable tank and work with in it’s

capabilities.

Removing the air tank:

1. Turn the On/Off switch (2) on the compressor to the

off position.

2. Turn the power supply off and disconnect the power cable.

3. Lift the main handle (1) up and away from the portable tank.