11

Fitting the keyed chuck

The keyed chuck (14) supplied as an accessory can be

fitted to the SDS chuck with the use of the SDS chuck

adaptor (12).

1. The keyed chuck allows bits with a straight shank to be

used with the tool.

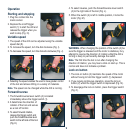

2. Grip and pull back the locking sleeve (11) and insert the

SDS chuck adaptor (12) (Fig. U).

3. It may be necessary to turn the SDS chuck adaptor in

order for it to locate properly (Fig. V).

U

V

4. Release the locking sleeve (11) to lock the adaptor in

place (Fig. W).

5. Screw the keyed chuck (14) onto the threaded end of the

SDS chuck adaptor (12) (Fig. X).

W

X

WARNING. The keyed chuck (14) is only to be

used in the

mode of operation.

It must

NOT BE USED when an SDS mode

is selected

, or .

Maintenance

WARNING. Always ensure that the tool is switched off and

the plug is removed from the power socket before making

any adjustments or maintenance procedures.

Store the tool, instruction manual and accessories in a

secure place. In this way you will always have all the

information and parts ready to hand.

Keep your machine and its cord clean. The outside of the

machine can be cleaned using a damp soft cloth with a mild

detergent if required.

Some maintenance products and solvents may damage the

plastic parts; these include products containing benzene, 25

trichloroethylene, chloride and ammonia.

CAUTION. Water must never come into contact with the tool.

Excessive sparking generally indicates the presence of dirt

in the motor or abnormal wear on the carbon brushes.

Take special care to keep the ventilation inlets/outlets free

from obstruction; cleaning with a soft brush followed by

a compressed air jet will usually be sufficient to ensure

acceptable internal cleanliness.

Wear eye protection when carrying out cleaning.

If the supply cord needs replacing, the task must be carried

out by the manufacturer, the manufacturer’s agent, or an

authorised service centre in order to avoid a safety hazard.

Regularly check that all the fixing screws are tight. They

may vibrate loose over time.

Regularly check to see if any dust or foreign matter has

entered the grills near the motor and around the trigger

switch. Use a soft brush to remove any accumulated dust.

Wear safety glasses to protect your eyes whilst cleaning.

Re-lubricate all moving parts at regular intervals.