8

Auxiliary handle and depth gauge

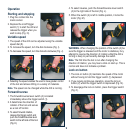

1. Turn the auxiliary handle (9) anti-clockwise to loosen the

collar and slip it over the chuck onto the drill (Fig. A).

2. Insert the depth gauge (10) in the hole at the top of the

handle (9) (Fig. B).

A

B

3. The auxiliary handle (9) can be swivelled around 360°

to find the position that offers most comfort and the

easiest operation.

4. The depth gauge (10) helps keep an accurate depth

when drilling holes to a set depth.

5. To change the position of the depth gauge (10), turn the grip

of the handle (9) anti-clockwise until the depth gauge is loose

enough to slide in the hole.

6. Set the depth, checking the depth with a steel rule for

most accurate measurement (Fig. C).

7. Then turn the handle grip clockwise to tighten both

the depth stop and the auxiliary handle in the required

position (Fig. D).

C

D

Installing and removing bits

CAUTION. Always ensure that the drill is switched off and

plug is removed from the power socket before installing or

removing drill bits.

The drill features an SDS-Plus

®

system which enables easy

and safe bit replacement.

Before inserting an SDS-Plus

®

bit always ensure that the bit

end is clean and greased.

1. Pull back the locking sleeve (11) and insert the bit into the

chuck opening taking care that the splines on the shaft of

the bit locate properly within the chuck (Fig. E).

2. Test for proper location by releasing the locking sleeve

(11) and giving the bit a sharp pull. If the bit can be

removed, again pull back the locking sleeve, rotate the bit

a fraction of a turn and re-insert it into the chuck (Fig. F).

E

F

3. Release the locking sleeve

and again test for proper

location. Repeat if necessary

until you are sure that the bit is

properly secured.

4. To remove the bit, pull back

the locking sleeve (11),

remove the bit, and release

the locking sleeve (Fig. G).

Note. Hammer action drilling is only possible with the drill

set for forward rotation.

G