16

3. Re-lubricate all moving parts at regular intervals.

4. If the body of the saw needs cleaning, wipe it with a soft

damp cloth. A mild detergent can be used but nothing like

alcohol, petrol or other cleaning agent.

5. Never use caustic agents to clean plastic parts.

General inspection

Regularly check that all the fixing screws are tight.

They may vibrate loose over time.

If the power cord or RCD needs replacing, the task must

be carried out by the manufacturer, the manufacturer’s

agent, or a qualified electrical repairer in order to avoid a

safety hazard.

Power cord and RCD maintenance

IMPORTANT. Ensure the RCD is tested upon every use.

It is essential that the safety switch is tested to ensure it is

functioning correctly. We strongly recommend that a test of

the RCD is conducted without fail before each use. Refer to

Testing your safety switch.

If the power cord or RCD needs replacing, the task must

be carried out by the manufacturer, the manufacturer’s

agent, or a qualified electrical repairer in order to avoid a

safety hazard.

Troubleshooting

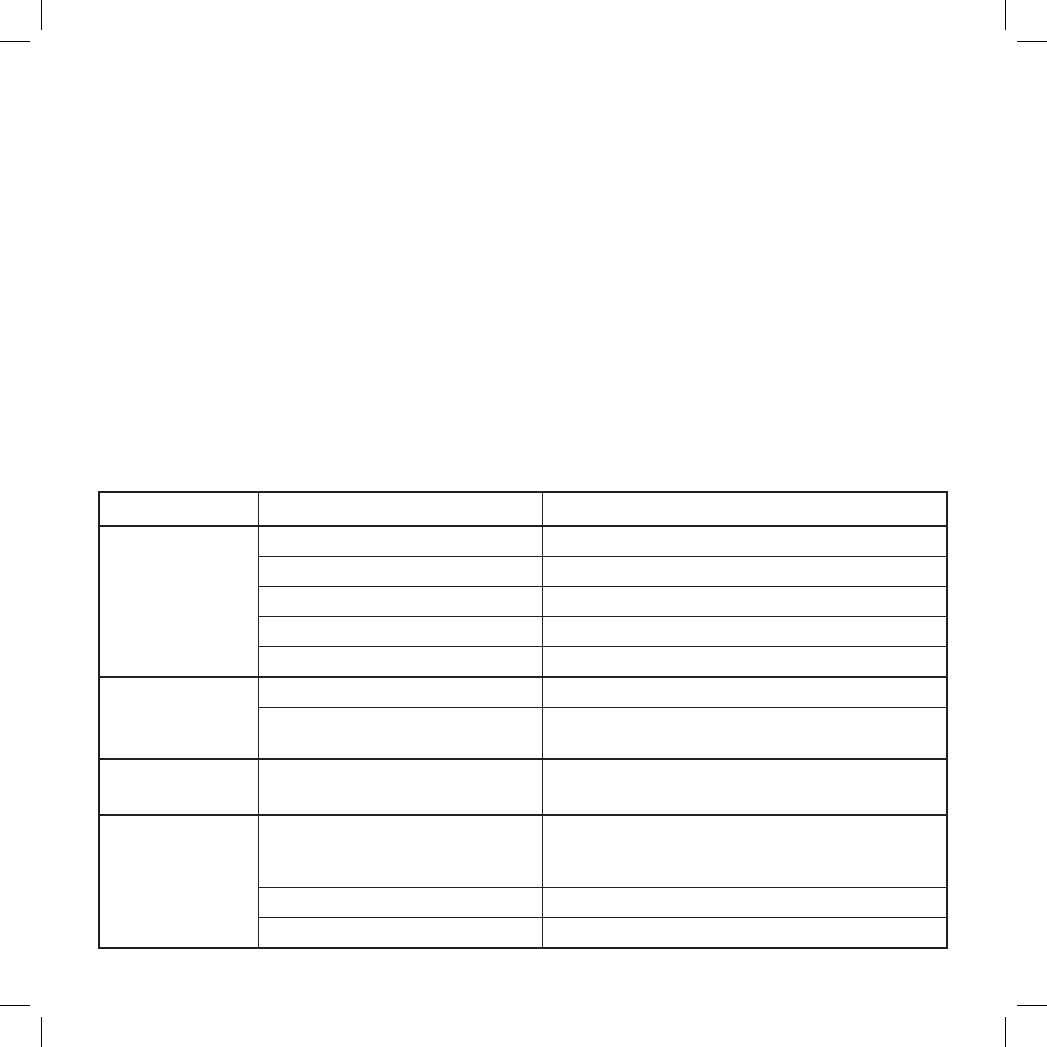

Trouble Problem Suggested remedy

Saw will not start Power cord not plugged in Ensure that the cord is connected to the power supply

Power fault, fuse or circuit breaker tripped Check the power supply

Cord damaged Use a qualified electrical repairer to repair or replace

Burned out switch Use a qualified electrical repairer to repair or replace

Faulty motor

Use a qualified electrical repairer to repair or replace the motor

Blade does not reach

full speed

Extension cord too long or undersized Use extension cord heavy enough to carry the current

Tool is overheating Turn off the tool and let it cool down to room temperature.

Inspect and clean the ventilation slots

Poor cutting Accessory blunted

No water on blade (tile cutting only)

Replace with new circular saw blade

Ensure water cooling on/off lever is in the “on” position

Vibration or abnormal

noise

Loose parts Check to see that all knobs and levers are securely

tightened including bevel adjustment lever, depth locking

lever and parallel fence locking knob

Blade vibrating Ensure that the blade nut is securely tightened

Moving parts excessively worn Use a qualified electrical repairer to repair or replace