Operation

20 3A2308C

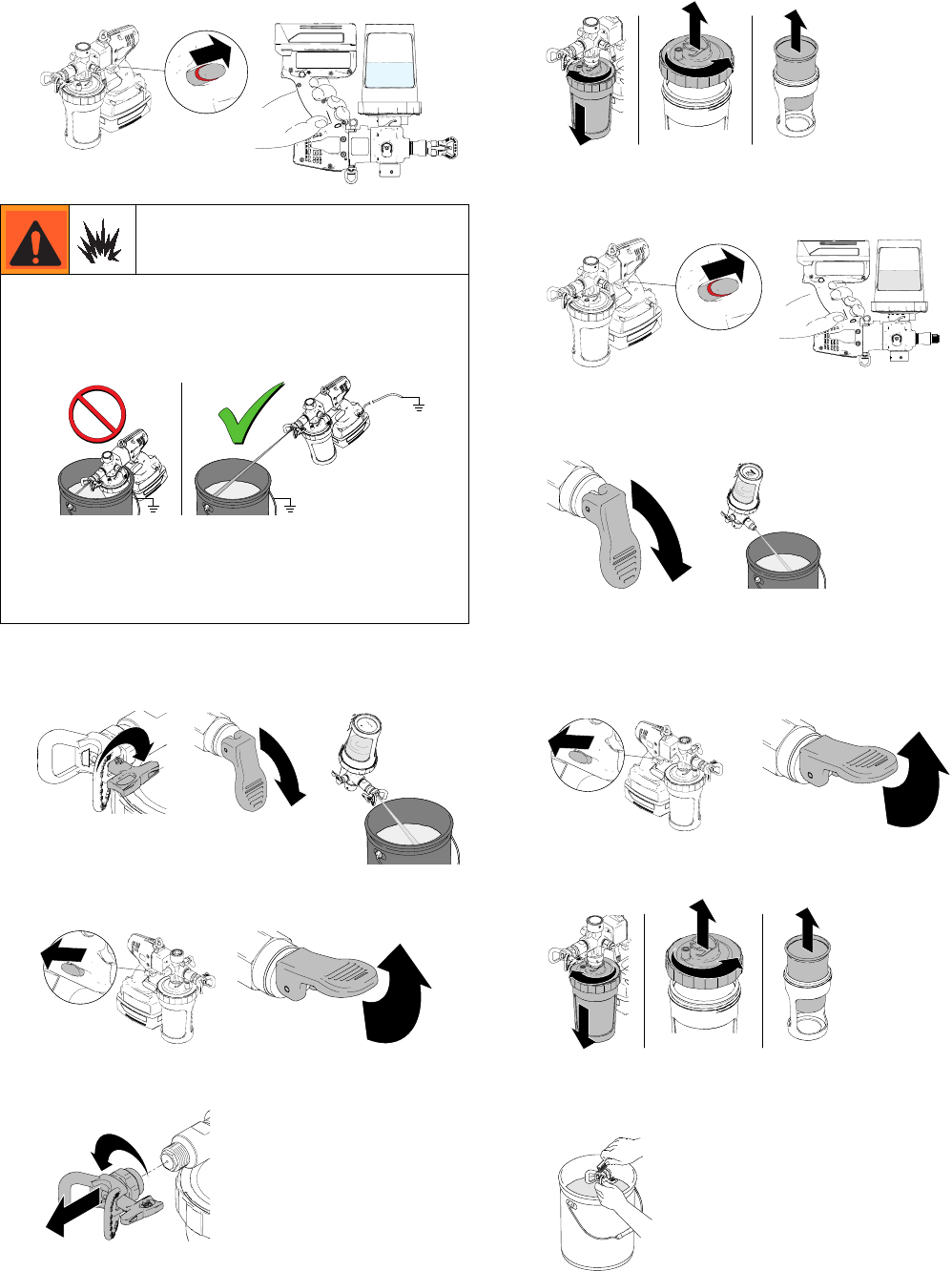

7. Disengage trigger lock, turn sprayer upside-down

and trigger for approximately 15 seconds to

recirculate material.

8. Reverse tip to UNCLOG position. Put prime/pres-

sure relief valve DOWN to spray position and trigger

sprayer through tip into waste area for 1- 2 seconds.

9. Engage trigger lock. Put prime/pressure relief valve

in UP position.

10. Unthread tip/guard from sprayer and soak in appro-

priate flushing fluid.

11. Remove cup and properly dispose contaminated

fluid.

12. Refill liner 1/2 full. Disengage trigger lock, turn

sprayer upside-down and trigger sprayer for

approximately 15 seconds to recirculate material.

13. Put prime/pressure relief valve DOWN to spray

position. Spray the remaining amount of cleaning

fluid through the front of the sprayer.

14. If sprayer is not completely clean, repeat steps 11

and 12.

15. Engage trigger lock and put prime/pressure relief

valve UP to release pressure.

16. Remove material liner and lid and properly dispose.

Properly dispose used fluid.

17. Clean Spray Tip/Guard assembly with clean flush-

ing fluid. Use a soft brush to loosen and remove

dried material if needed.

To avoid serious injury or damage to equipment, do not

expose the sprayer electronics to flushing solvents.

Keep sprayer at least 10 in. above the rim of the con-

tainer when flushing.

Keep spray area well-ventilated. Keep a good supply

of fresh air moving through the area. When flushing

with solvents, always ground the sprayer and waste

container.

ti14994a

ti19374a

ti19798a

ti14995a

ti19346a

ti19366a

ti19370a

ti19350a

ti19347a

ti19386a

ti19385a

ti19374a

ti19358a

ti19346a

ti19404a

ti19350a

ti19347a

ti19385a

ti19344a