6 308253

Operation

Pressure Relief Procedure

WARNING

SKIN INJECTION HAZARD

The system pressure must be manually

relieved to prevent the system from

starting or spraying accidentally. Fluid

under high pressure can be injected through the

skin and cause a serious injury. To reduce the risk

of an injury from injection, splashing fluid, or mov-

ing parts, follow the Pressure Relief Procedure

whenever you:

D are instructed to relieve the pressure,

D stop dispensing,

D check or service any of the system equipment,

D or install or clean the nozzle.

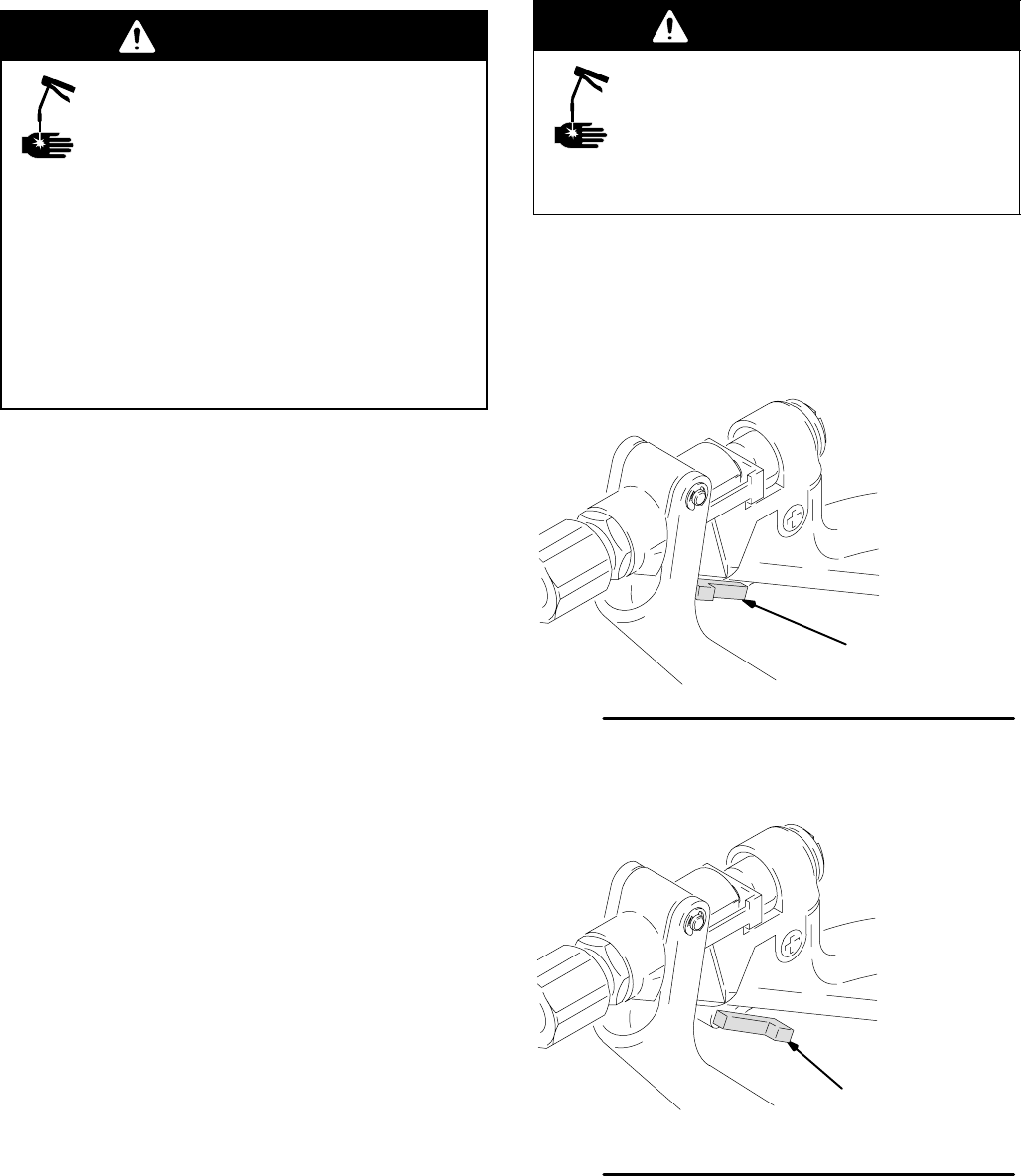

1. Fully release the gun trigger and lock the gun

trigger safety by rotating the safety forward. See

Fig. 1.

2. Shut off the fluid supply pump.

3. Hold a metal part of the gun firmly to the side of a

grounded metal waste container. Unlock the gun

trigger safety by rotating the safety backward. See

Fig. 2. Trigger the gun to relieve fluid pressure.

4. Fully release the gun trigger and lock the gun

trigger safety by rotating the safety forward.

5. Open the pump drain valve to help relieve fluid

pressure in the pump, hose, and gun. Triggering

the gun to relieve pressure may not be sufficient.

Have a container ready to catch the drainage.

6. Leave the drain valve open until you are ready to

dispense again.

7. If you think that the gun nozzle or fluid hose is

completely clogged or that pressure has not been

fully relieved after following the steps above, very

slowly loosen the hose end coupling and relieve

pressure gradually, then loosen the coupling

completely. Clear the nozzle or hose obstruction.

Gun Trigger Safety

WARNING

SKIN INJECTION HAZARD

To prevent accidental triggering of the

gun and reduce the risk of a serious

injury, including fluid injection or splash-

ing in the eyes or on skin, lock the gun trigger

safety when you stop dispensing.

To lock the gun safety, release the trigger and rotate

the safety toward the trigger as shown in Fig. 1.

NOTE: Do not try to force the trigger valve open with

the safety engaged. This could result in component

failure.

Fig. 1

01610

A

Locked

To unlock the trigger safety, rotate the safety toward

the handle as shown in Fig. 2.

Fig. 2

Unlocked

01610

A