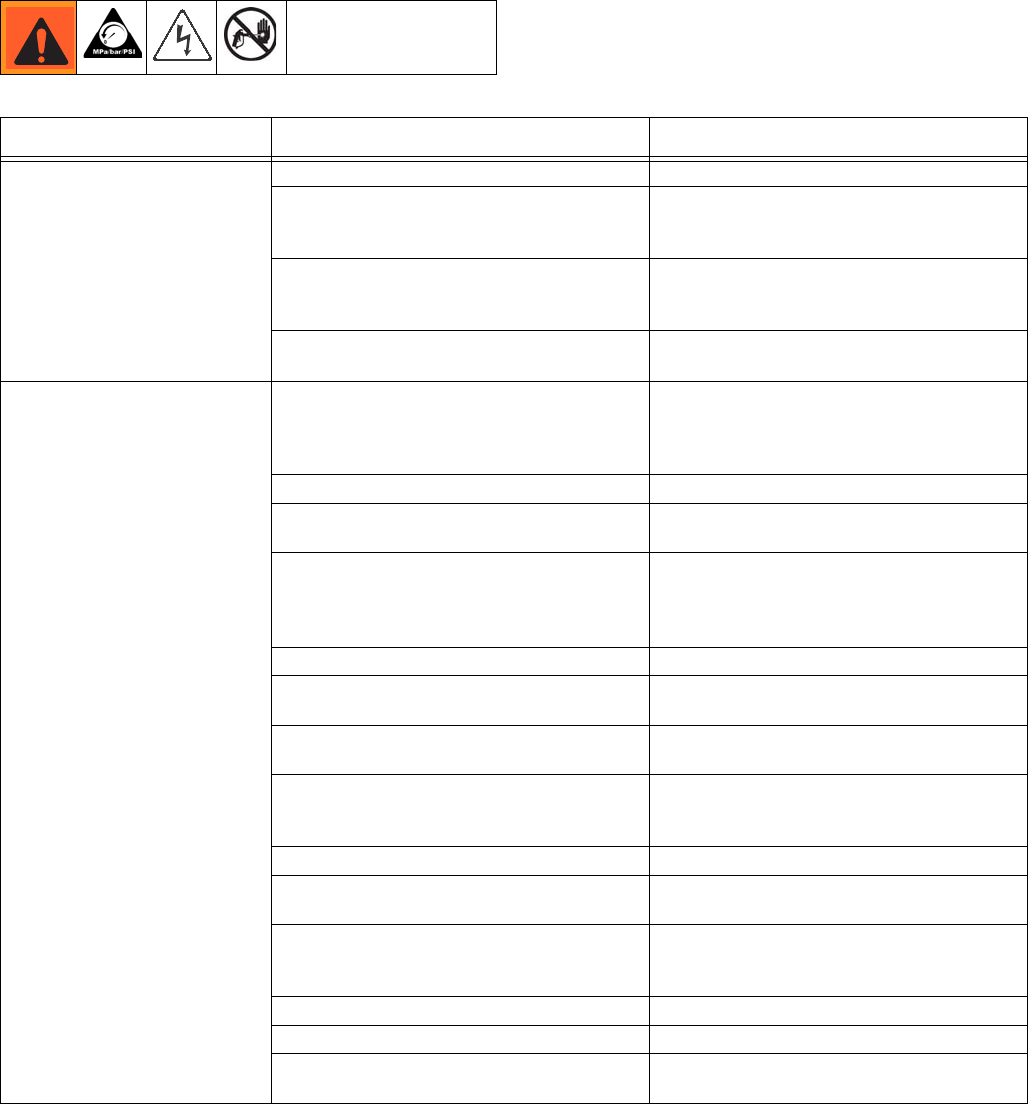

Troubleshooting

18 3A0705E

Troubleshooting

Check everything in this Troubleshooting Table before

you bring the sprayer to an authorized service center.

Problem Cause Solution

Sprayer makes no sound when

trigger is pulled

Trigger is locked. Disengage trigger lock. See page 6.

Status Indicator Light is solid RED when trig-

gering, indicating that the battery charge is

low or the battery is too cold.

Replace with charged battery and place old

battery in charger or allow the battery to warm

up.

Status Indicator Light is flashing RED when

triggering, indicating that the battery is too hot

to operate.

Allow battery to cool.

Status Indicator Light does not light when

sprayer is triggered.

Battery is not installed or is

damaged.

Sprayer makes sound but no

material is sprayed when trigger

is pulled

Sprayer is not primed. Prime the pump. See Starting a new Job (or

Refilling the Cup), page 10. If sprayer fails to

prime, follow Inlet Valve Cleaning (page 22)

and/or Alternate Priming Method (page 21).

Prime/relief valve is in UP position. Pull valve DOWN to spray position.

Suction Tube is missing or improperly

installed.

Make sure Suction Tube is properly installed.

Inlet valve is stuck from material

residue left in sprayer.

Use a pencil or thin rod to lightly push on inlet

valve to make sure it moves up and down

freely. See Starting a new Job (or Refilling

the Cup), page 10.

Tip is not in SPRAY position. Turn tip to SPRAY position.

Tip is clogged. See Unclogging Tip/Guard

Assembly, page 13.

Suction Tube screen is clogged or vent holes

in black rubber inlet seal are clogged.

See Shutdown and Cleaning, page 14.

Sprayer has been tilted too far and suction

tube has lost contact with material.

Make sure cup is filled with material. Do not tilt

the cup too far. Prime the pump. See Starting

a new Job (or Refilling the Cup), page 10.

No or low material in cup. Refill cup with material.

Tip filter is clogged. Remove and clean tip filter. See Unclogging

Tip/Guard Assembly, page 13.

Fine Finish Optimizer is installed while using

an incompatible material.

Make sure compatible material is being used.

See Reversible Tip Selection Chart, page

11.

Suction Tube o-rings are damaged or missing. Replace Suction Tube and o-rings.

Sprayer has reached maximum life. Replace sprayer.

Material is leaking from hole in front of

sprayer.

Replace sprayer.