Spray Pattern Adjustment

16 311320H

e. If buildup recurs shortly after cleaning

tip, remove air cap and ensure inside is

clean.

Reinstall air cap and ensure airflow is properly

set.

If no buildup occurred on air cap, check the fol-

lowing items in this order and readjust if neces-

sary:

• Check Valving Rod Adjustment

Screw/Sleeve setting.

• Check hose temperature setting.

• Check primary heater temperature setting.

• Ensure spray pressures between chemi-

cals are balanced. If they are not, refer to

Troubleshooting section of Proportioning

Unit Operation Manual for the proportioner

in use.

• Ensure flow of air to air cap is adequate but

not excessive.

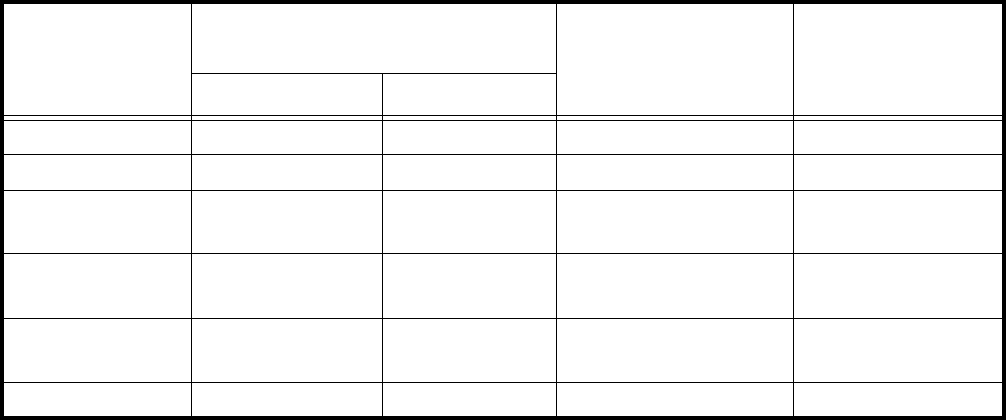

Table 1: Valving Rod Adjustment for Standard Mixing Chambers

Chamber

Turns Out From Point of

Valving

Recommended

Distance of Gun

from Surface Pattern SizeMinimum Maximum

46-800 1/2 turn 2 turns 12 in. (304-8 mm) 6 in. (152.4 mm)

46-810 1/2 turn 2 turns 12 in. (304-8 mm) 6 in. (152.4 mm)

55-776 1 3/4 turns 2 5/8 turns 18 to 20 in. (457.2

to 508 mm)

8 in. (203.2 to

228.6 mm)

62 2 turns 3 turns 18 to 20 in. (457.2

to 508 mm)

8 to 9 in. (203.2

to 228.6 mm)

70 2 turns 3 turns 18 to 20 in. (457.2

to 508 mm)

10 to 12 in. (254

to 304.8 mm)

78-851 2 turns 3 turns 24 in. (609.6 mm) 14 in. (355.6 mm)