Operation

3A0235G 13

Operation

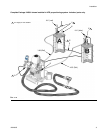

Startup

1. See Load fluid with feed pumps in system opera-

tion manual.

2. Open feed pump air regulator.

3. Open feed pump bleed-type master air valve.

4. Adjust air to feed pump with needle valve.

NOTE:

• Cold, viscous material may be difficult to prime.

Use needle valve to reduce air flow to motor.

• Do not plug or shut off pump fluid outlet when

priming. Fluid must be free to flow through

pump to prime.

• To increase pump flow rate and reduce icing,

remove pump muffler. This will increase exhaust

noise.

5. Never let pump run when drum is empty. A dry

pump can accelerate and damage itself. If pump is

running too fast, stop it immediately. Check and refill

fluid supply, or flush with compatible solvent. Always

prime entire system to remove any air. Do not let

material harden in pump.

Shutdown

See Shutdown and Pressure Relief Procedure in system

operation manual. Close feed pump bleed-type master

air valve.

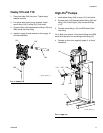

Changing Drums

1. See Shutdown above.

2. Remove riser tube from drum. Install in new drum,

page 8.

3. Lubricate bung o-ring, page 8.

4. See Load fluid with feed pumps in GMS operation

manual.

Maintenance

NOTE:

See supplied pump manual for maintenance, repair, and

parts information.

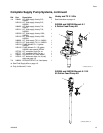

Lubricate bung o-ring (309) with 217374 ISO Pump Oil

each time you change drums. This keeps air and mois-

ture from reacting with ISO.

Whenever pump is removed from drum, inspect bung

o-ring (309) and gasket (303) in place. If either is worn

or damaged, or if ISO shows signs of crystallization,

replace. See page 22.

Tighten pump clamps and external fasteners periodi-

cally. See pump manual.

Repair

See supplied pump manual for maintenance, trouble-

shooting, and repair procedures.

NOTICE

To prevent cross-contamination of fluid when chang-

ing drums, complete changing one component

before changing second component.