Repair

30 309295

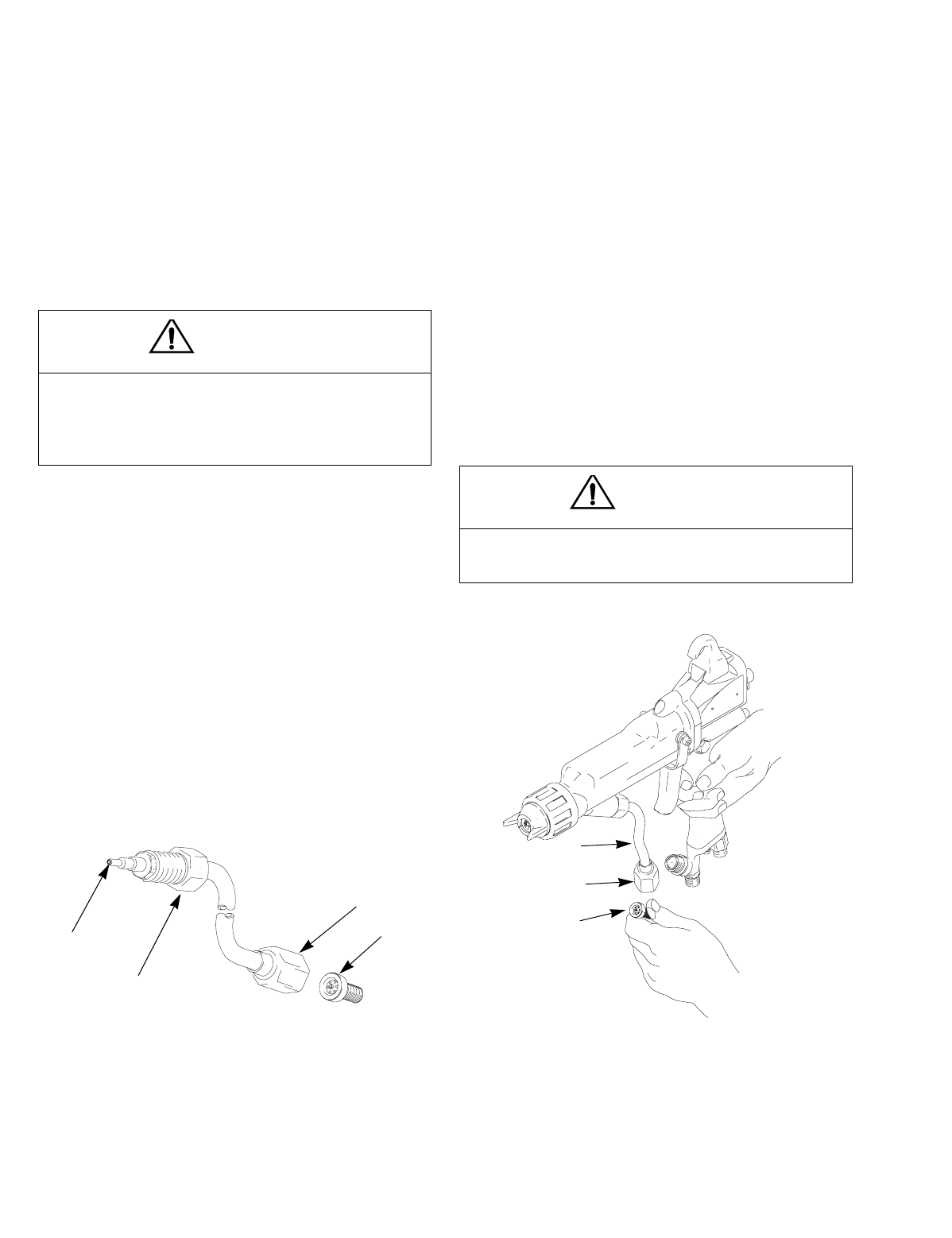

Fluid Tube Replacement

1. Prepare the gun for service, page 26.

2. Disconnect the bottom fluid tube nut (C). See Fig.

11.

3. Carefully unscrew the top fluid tube nut (D).

4. Apply dielectric grease (40) to the entire length of

the plastic extension on the end of the fluid tube

(14).

5. Apply low strength thread sealant to the fluid tube

nut threads.

6. Install the fluid tube into the gun barrel and tighten

the top nut (D) hand-tight, then 1/4 to 1/2 turn

with a wrench. There will be a gap between the nut

and barrel. Do not overtighten the nut.

7. Make sure the fluid filter (1) is in place in the fluid

fitting. Tighten the bottom nut (C) onto the fitting

and torque to 20-30 in-lb (2.3-3.4 N•m). Make sure

the top nut remains tight.

Fig

.

1

.

Fig. 11. Fluid Tube Replacement

Fluid Filter Removal

1. Prepare the gun for service, page 26.

2. Disconnect the bottom fluid tube nut (C).

3. Remove the fluid filter (1) from the fluid fitting.

Clean or replace the filter, as needed. See Fig. 12.

NOTE:

Replacement filters are available in 100 mesh

(standard) or 60 mesh sizes. See page 47.

4. Install the fluid filter in the fluid fitting. Tighten the

bottom nut (C) onto the fitting and torque to 20-30

in-lb (2.3-3.4 N•m). Make sure the top nut remains

tight.

Fig

.

1

.

Fig. 12. Fluid Filter Removal

CAUTION

Be careful not to damage the fluid tube assembly (14)

when cleaning or installing it, especially the sealing

surface (E). If the sealing surface is damaged, the

entire fluid tube assembly must be replaced.

ti1524a

C

D

E

1

CAUTION

Be sure the fluid tube (14) is not twisted after tighten-

ing the bottom nut (C).

TI1521A

C

1

14