5308–367

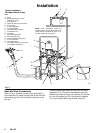

Installation

Be sure that all operators read and understand this

entire manual and the separate manuals supplied with

components and accessories before using this equip

-

ment.

Reference numbers and letters in parentheses refer to

the figures and parts drawings.

Accessories mentioned are available from your Graco

distributor

. If you supply your own accessories, be sure

they area adequately sized to meet your system’

s

requirements.

The T

ypical Installation shown in Fig. 4 is only an

example. For assistance in designing a system to meet

your particular needs, contact your Graco distributor

.

System Accessories

WARNING

Two

required components are supplied with your

pump, to help reduce the risk of serious injury

including fluid injection, splashing in the eyes or on

the skin, or injury from moving parts if you are

adjusting or repairing the pump.

The

bleed-type master air valve (B)

relieves air

trapped between this valve and the pump. T

rapped

air can cause the pump to cycle unexpectedly

.

To

bleed air from the pump, the pump air regulator

(F) must be open when you close this valve.

The

fluid drain valve (H)

assists in relieving fluid

pressure in the displacement pump, hose, and gun;

triggering the gun to relieve pressure may not be

sufficient.

Install an air line filter (E) in the main air line, to re

-

move harmful dirt and moisture from the compressed

air supply

. T

o provide automatic lubrication of the air

motor

, install an air line lubricator (P) downstream from

the pump air regulator (F). Install a second master air

valve (D) in the main air line, to isolate the accessories

for servicing.

Grounding

T

o reduce the risk of static sparking, ground the pump,

object being sprayed, and all other spray equipment

used or located in the spray area. Check you local

electrical code for detailed grounding instructions for

your area and type of equipment. Be sure to ground all

of this spray equipment.

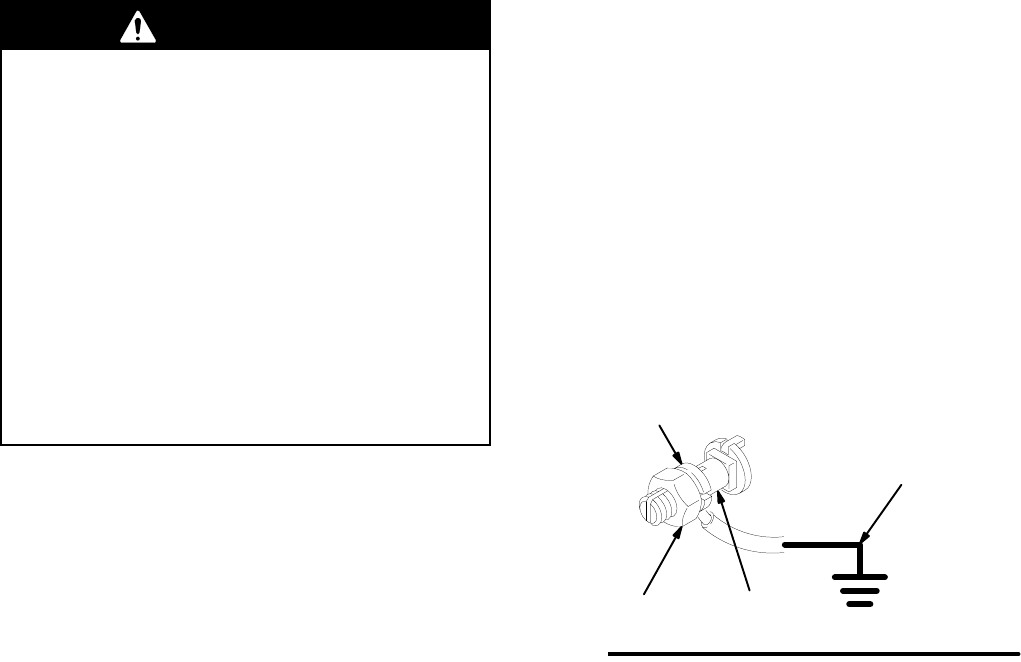

1.

Pump:

loosen the grounding lug locknut (W) and

washer (X). Insert one end of a 1.5 mm

2

(12 ga)

minimum ground wire (Y) into the slot in lug (Z)

and tighten the locknut securely

. See Fig. 3. Con

-

nect the other end of the ground wire to a true

earth ground.

2.

Air hoses:

use only grounded air hoses.

3.

Fluid hoses:

use only grounded fluid hoses.

4.

Air compressor:

follow manufacturer

’

s recommen

-

dations.

5.

Spray gun:

grounding is obtained through connec

-

tion to a properly grounded fluid hose and pump.

6.

Fluid supply container:

according to your local

code.

7.

Object being sprayed:

according to your local

code.

8.

All solvent pails used when flushing,

according to

local code. Use only metal pails, which are con

-

ductive, placed on a grounded surface. Do not

place the pail on a non-conductive surface, such

as paper or cardboard, which interrupts the

grounding continuity

.

9.

T

o maintain grounding continuity when flushing or

relieving pressure

, always hold a metal part of the

spray gun firmly to the side of a grounded metal

pail, then trigger the spray gun.

Fig. 3

W

X

Y

Z

0864