13

307–760

REPAIR

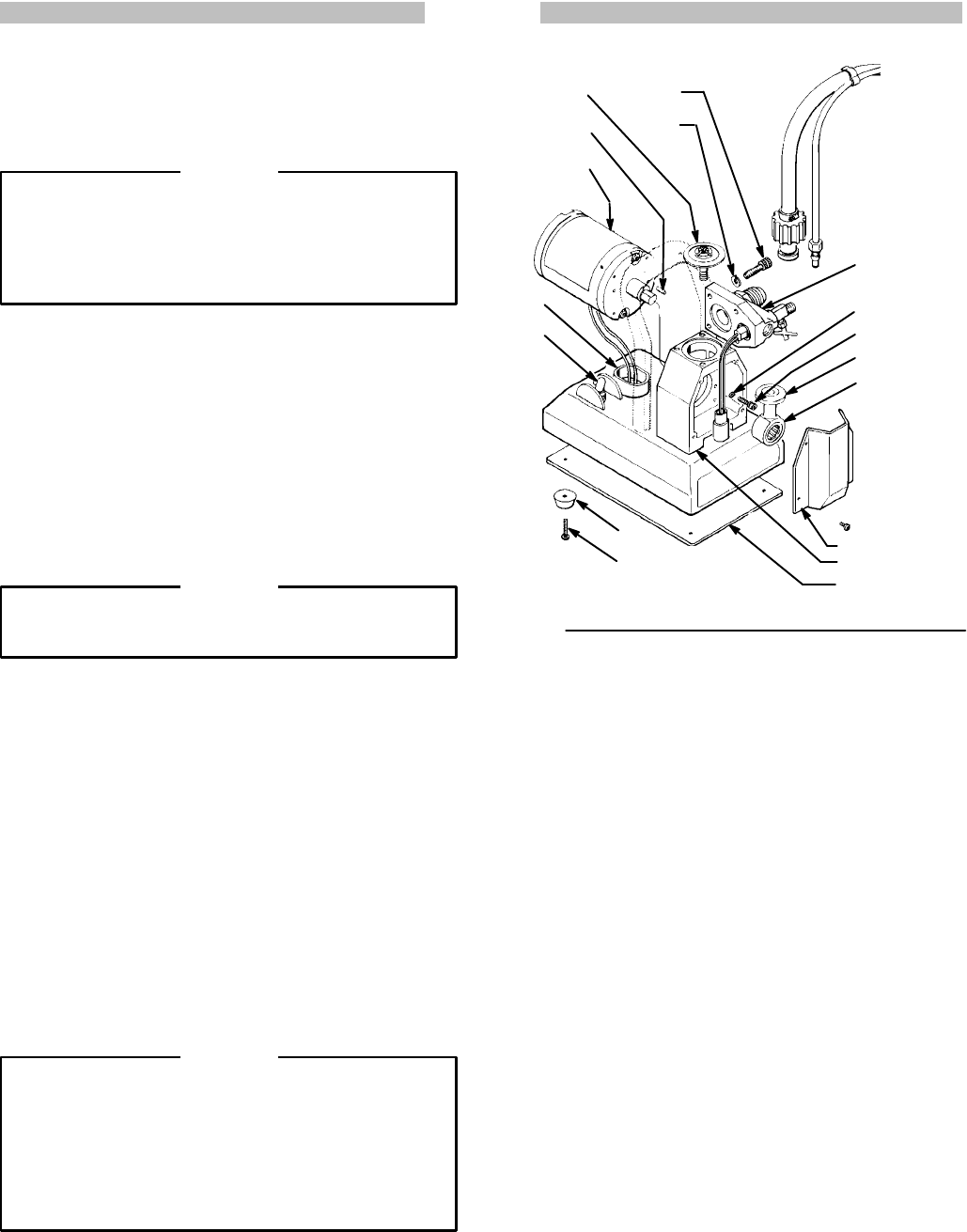

Connecting Rod and Bearing (See Fig 16)

1.

Remove the front cover plate (23). Remove the

screws (15) and tip the pump housing (9) out of the

way.

Unscrew the diaphragm (17) and discard.

CAUTION

Replace the diaphragm (17) whenever you remove

the

pump housing (9). During use, small grooves are

formed in the diaphragm which cannot be realigned

properly. Reusing a diaphragm may cause leaking

which

will result in costly damage to the pump.

2.

Remove the motor screws (20). Lift the motor (30)

slightly. Holding the connecting rod, pull the motor

away

from the housing (22).

3.

Inspect the bearing (18b) in the connecting rod (18).

If it is worn or any rollers are broken, replace the

bearing

and rod assembly

(18). Inspect the motor ec

-

centric (F), and replace the motor if the eccentric is

worn.

4.

Use

your fingers to pack high–quality bearing grease

thoroughly

in between the bearing rollers.

CAUTION

Thorough

greasing of the

bearing is essential to ex

tend

the life of the bearing and

the motor eccentric.

5.

Use

a soft

brass or nylon bristle brush to clean the top

of

the

connecting rod and housing. Gently clean the

bottom

of the pump housing (9), avoiding damage to

the

diaphragm grooves.

6.

Install

the connecting rod (18) in the connecting

rod

housing (22). Screw a new diaphragm (17) into the

rod

just

until it bottoms. T

urn the diaphragm

only

1/4

to

1/2 turn more (2.7–3.6 N.m [6–8 in–lb]).

7.

Align the motor with the pins in the connecting rod

housing

(22), guiding the motor eccentric through the

connecting

rod bearing (18b). Spin the motor shaft to

be

sure it moves freely

.

8.

Loosely

install the lockwashers (21)

and screws (20).

Spin the motor shaft again. Now alternately tighten

the

screws. Spin the motor shaft again.

CAUTION

Spinning the motor shaft while assembling the

pump

ensures that parts

are properly aligned. If they

are not, and you start the pump, serious damage

could result to the motor, bearing, and connecting

rod. If you feel binding or resistance, disassemble

the parts, checking the spin often, until you deter-

mine

the cause of the binding.

9.

Position

the pump housing (9) on

the sprayer

. Lubri

-

cate the screws (15) and install them and the Iock-

washers

(16) loosely

. T

orque the screws a few

inch–

pounds

(N.m) at a time, oppositely and evenly

, to

85

in–lb

(9.8 N.m).

10.

Reinstall the front cover plate (23).

30

Fig 16

9

21

20

18a

18b

23

22

42

43

33

34

69

17

15

16

PRESS

FIT

INT

O 22

GREASE

BEARING

THOROUGHLY

Motor

(See Fig 16)

1.

Remove the front cover plate (23).

2.

Remove the bumpers (43) and the bottom cover

plate

(42). Disconnect the

motor leads from the posi

-

tive

and negative rectifier terminals. See Fig 1

1, page

12.

3.

Remove

the motor screws. Lift the motor (31)) slight

-

ly. Holding the connecting rod, pull the motor away

from

the housing (22).

4.

Inspect

the bearing (18b)

in the connecting rod (18).

If it is worn or any rollers are broken, replace the

bearing and rod assembly (18) as instructed to the

left.

5.

Use

your fingers to pack high-quality bearing grease

thoroughly

in between the bearing rollers.

6.

Feed the motor leads through the rubber grommet

(69).

Align the motor with the pins in the connecting

rod housing (22), guiding the motor eccentric

through the connecting rod bearing (18b). Spin the

motor

shaft to be sure it moves freely

.

7.

Loosely

install the lockwashers (21)

and screws (20).

Spin the motor shaft again. Alternately tighten the

screws. Spin the motor shaft again. See the CAU-

TION

in Step 8 to the left.

8.

Connect

the red motor lead to the positive (+) termi

-

nal

and the black motor lead to the negative (–) termi

-

nal

of the rectifier (39). Refer to Fig 1

1.

9.

Reinstall the front cover plate.