Service

Adjusting

the Needle

Packings

The needle packings require adjustment once a

month under normal use to ensure fluid does not leak

back through the needle packings. The needle pack-

ings must also be adjusted whenever

the

needle

is

removed or adjusted.

To

adjust the needle packings:

1.

First flush the gun as instructed on page

14.

2.

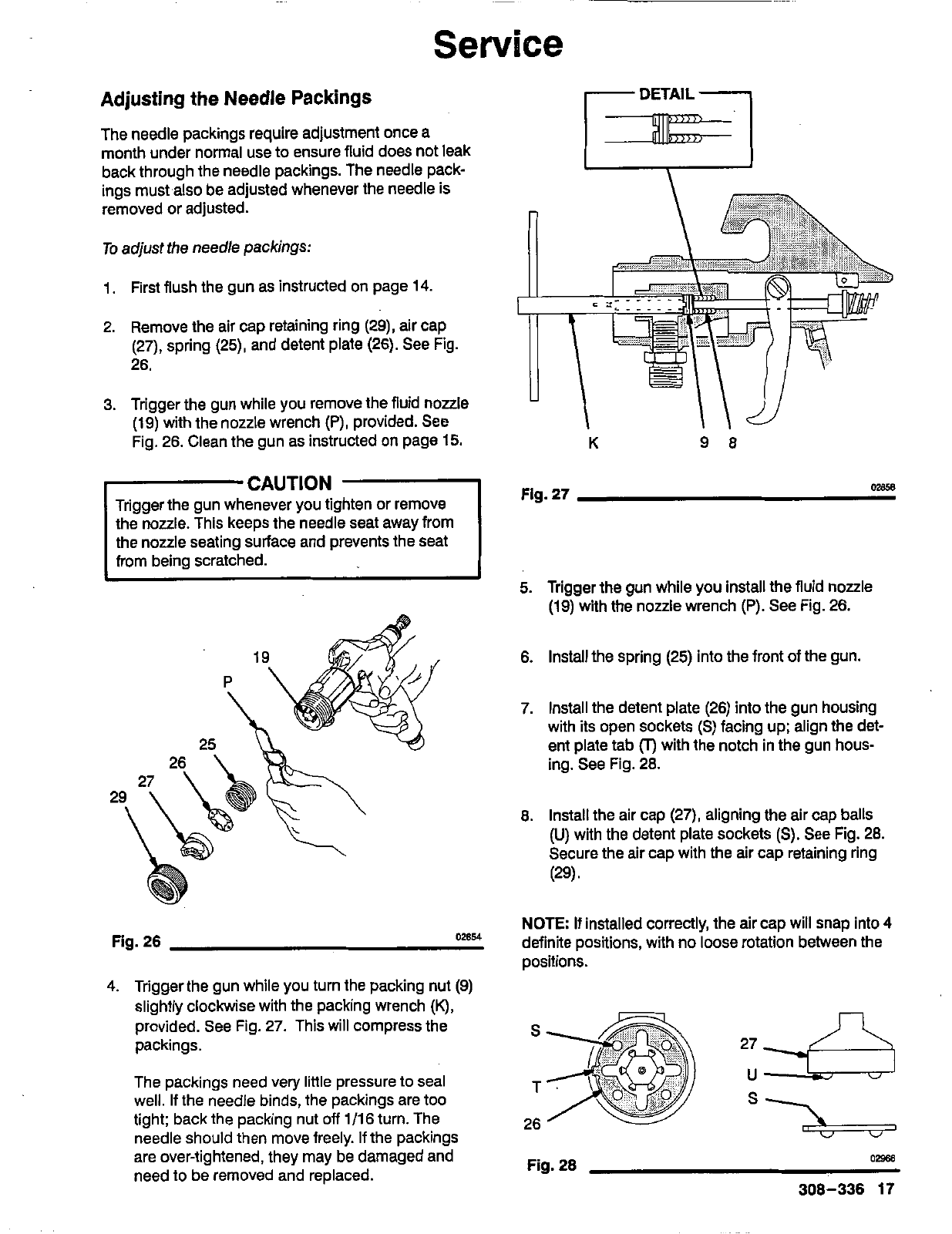

Remove the air cap retaining ring

(29),

air cap

26.

(27),

spring

(25),

and detent plate

(26).

See Fig.

3.

Trigger the gun while you remove the fluid nozzle

Fig.

26.

Clean the gun as instructed on page

15.

(19)

with the nozzle wrench

(P),

provided. See

ICAUTIOY

1

Trigger the gun whenever you tighten or remove

the nozzle. This keeps the needle seat away from

the nozzle seating surface and prevents the seat

from beina scratched.

K

98

5.

Trigger the gun while you install the fluid nozzle

(19)

with the nozzle wrench

(P).

See Fig.

26.

6.

Install the spring

(25)

into the front of the gun.

7.

Install the detent plate (26) into the gun housing

with its open sockets

(S)

facing

up;

align the det-

ent plate tab

0

with the notch in the gun hous-

ing. See Fig.

28.

8.

Install the air cap

(27),

aligning the air cap balls

(U)

with the detent plate sockets

(S).

See Fig.

28.

Secure the air cap with the air cap retaining ring

(29).

Fig.

26

4.

Trigger the gun while you turn the packing

nut

(9)

slightly clockwise with the packing wrench

(K),

provided.

See

Fig.

27.

This will compress the

packings.

The packings need very

little

pressure to

seal

tight; back the packing nut

off

1/16

turn. The

well. If the needle binds, the packings are

too

are over-tightened, they may be damaged and

needle should then move freely. If the packings

need to be removed and replaced.

02854

NOTE

If installed correctly, the air cap will snap into

4

definite positions, with no loose rotation between the

positions.

Fig.

28

02868

308-336

17