Introduction

The Series

700

Turbine Spray Gun can spray most and directs the paint from the gun to the surface,

coatings or finishes currently being used for automo-

tive

refinish, industrial, aerospace, marine, wood,

minimizing overspray and increasing transfer em-

plastic and architectural applications.

ciency. This enables painters to comply with new

clean air laws that are designed to reduce

VOC

(vola-

This spray gun typically utilizes

5

psi

(0.35

bar)

tile organic compounds) emissions, eases paint

inbound air pressure to produce high quality paint

application by requiring fewer paint passes to obtain

finishes. The gun produces a cone of air that carries

coverage, and saves on both material and clean-up

time.

Fluid

Set

Selection

Charts

Using the Charts

Unless otherwise ordered, the Turbine Spray Gun

size

of

the a/r cap, fluid nozzle, and fluid needle are

includes a

1.4

mm fluid set, part no.

M70581.

The

marked on the parts.

Use

the fluid set charts on page

5

to order a different

size

fluid set or to find the part number of an indivi-

dual component of your fluid set. The charts separate

fluid sets that are commonly used in contractor

applications from those commonly used in automotive

applications.

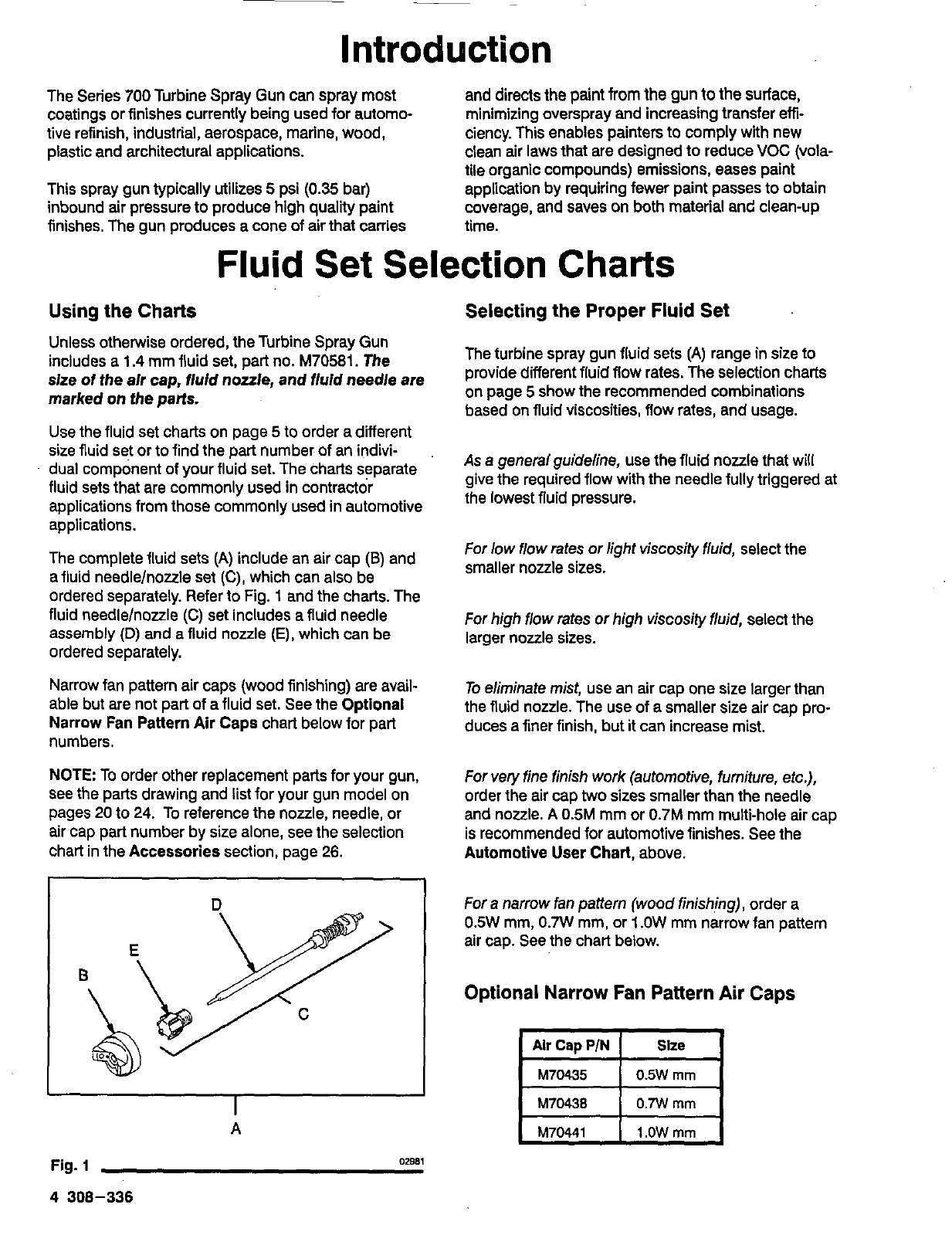

The complete fluid sets

(A)

include an air cap

(a)

and

afluid needlelnozzle set

(C),

which can also be

ordered separately. Refer to Fig.

1

and the charts. The

fluid needlelnoule

(C)

set includes a fluid needle

assembly

(D)

and

a

fluid nozzle

(E),

which can be

ordered separately.

able but are not part of afluid

set.

See the Optional

Narrow fan pattern air caps (wood finishing) are avail-

Narrow Fan Pattern Air Caps chart below for part

numbers.

see the parts drawing and list for your gun model on

NOTE To order other replacement parts for your gun,

pages

20

to

24.

To reference the nozzle, needle, or

air cap part number by

size

alone, see the selection

chart in the Accessories section, page

26.

A

Fig.

1

02981

4

308-336

Selecting the Proper Fluid Set

The turbine spray gun fluid sets

(A)

range in size to

provide different fluid flow rates. The selection charts

on page

5

show the recommended combinations

based on fluid viscosities, flow rates, and usage.

As

a general guideline, use the fluid nozzle that will

the lowest fluid pressure.

give the required flow with the needle fully triggered at

For low flow rates

or

light viscosily fluid, select the

smaller nozzle sizes.

For

high

flow rates

or

high viscosity fluid, select the

larger nozzle sizes.

To

eliminate mist, use an air cap one size larger than

the fluid nozzle. The use of a smaller size air cap pro-

duces a finer finish, but it can increase mist.

For very fine finish work (automotive, furniture, etc.),

order the air cap

two

sizes smaller than the needle

and nozzle.

A

0.5M

mm or

0.7M

mm multi-hole air cap

Automotive User

Chart,

above.

is recommended for automotive finishes. See the

For a narrow

fan

pattern (wood finishing), order a

0.5W

mm,

0.7W

mm, or

1

.OW

mm narrow fan pattern

air cap. See the chart below.

Optional Narrow Fan Pattern Air Caps

Alr

Cap

P/N

Slze

M70435

1

.OW

mm

M70441

0.7W

mm

M70438

0.5W

rnm

~