G0641 Double Miter Saw

-33-

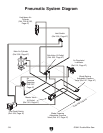

Pneumatic System

Symptom Possible Cause Possible Solution

Hold-downs/blade

pivot arms not

responding.

1. Air pressure not adequate.

2. Air regulator-lubricator or internal regulator

at fault.

3. Hold-down/main air cylinder at fault.

4. Hold-down/blade speed valve(s) at fault.

5. Air line pinched/clogged.

6. Sub/master valve is at fault.

7. Foot pedal actuator at fault.

1. Connect machine to an air supply of

70–90 PSI; adjust air regulator-lubricator and inter

-

nal air regulator to 70 PSI.

2. Test/replace; adjust to 70 PSI.

3. Test/replace.

4. Test/replace.

5. Use Pneumatic System Diagram (

Page 38) to trace

air flow; check for pinched/clogged air line and air

flow at connections; clean/repair/replace as need

-

ed.

6. Test/clean/replace.

7. Test/clean/replace.

Hold-downs not

securing workpiece

when cutting.

1. Hold-downs not properly adjusted.

2. Hold-downs not completely lowering before

blades begin cut.

3. Hold-down neoprene tips glazed or worn.

1. Properly adjust hold-downs for workpiece (

Page

19).

2. Correctly adjust hold-down and blade lowering

speeds (

Page 20).

3. Re-dress hold-down tips with fine grit sandpaper;

replace.

Hold-downs not

raising after cut.

1. Pneumatic limit switch at fault.

2. Master or sub-valve at fault.

1. Reposition/test/replace limit switch (

Page 35).

2. Test/replace.

Blade pivot arms not

raising after cut.

1. Master or sub-valve at fault.

2. Foot pedal actuator at fault.

1. Test/replace.

2. Test/replace.