-18-

Model G0477 15" Planer/Moulder

Note: If the cut is too heavy and bogs down

the planer/moulder, turn the planer/moulder

OFF immediately, allow it to come to a com-

plete stop, remove the workpiece, and repeat

Steps 3–5.

6. Measure your workpiece thickness and adjust

the headstock height as necessary to take a

lighter or heavier pass, depending on your

needs.

Operation Tips

• Inspect lumber for defects, warping, cup-

ping, twisting, and for foreign objects (nails,

staples, imbedded gravel, etc,). If you have

any question about the quality of your lum-

ber, do not use it. Remember, wood stacked

on a concrete floor can have small pieces of

stone or concrete pressed into the surface.

• Use the full width of the planer/moulder.

Alternate between the left, the right, and the

middle when feeding lumber into the planer/

moulder. Your cutters will remain sharp much

longer.

• Scrape all glue off joined boards before plan-

ing.

• Plane ONLY natural wood fiber. DO NOT

plane MDF, plywood, laminates, or other

synthetic products.

• Plane wood with the grain. Never feed

end-cut or end-grained lumber into your

planer/moulder.

• Do not use boards with loose or large knots,

splits, crossgrain or other obvious blemishes

or defects. They can damage the machine

and pose the possibility of operator injury.

• Keep your work area clear.

• When making multiple passes on long stock,

use the stock return rollers on the top of the

machine to move the material back to the

infeed side of the machine.

• Avoid planing wood with a high water con-

tent. Wood with more than 20% moisture

content or wood exposed to excessive mois-

ture (such as rain or snow), will plane poorly

and cause excessive wear to the cutters and

motor. Excess moisture can also hasten rust

and corrosion of the planer/moulder and/or

individual components.

Feed Speed

The infeed and outfeed rollers power the stock

through the planer/moulder while keeping boards

flat and providing a consistent rate of movement.

The power feed features 22 FPM and 11 FPM

feed rates. The speed should be changed ONLY

when the machine is running.

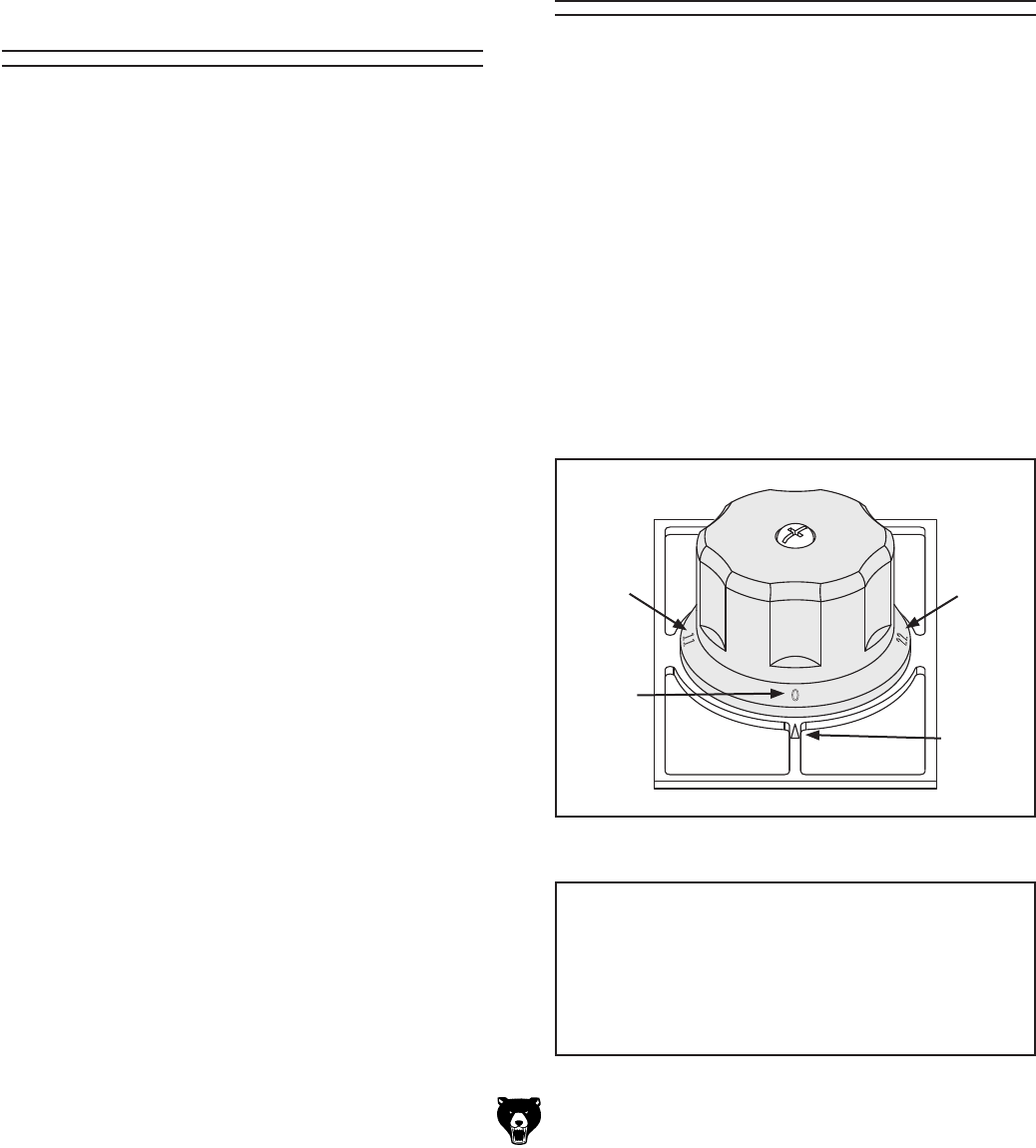

Figure 11 illustrates the three different positions

of the feed control knob. Turning the knob clock-

wise sets the feed speed to 22 FPM (used for

rough planing). Turning the knob counterclock-

wise sets the feed speed to 11 FPM (used for

finishing and moulding). Turning the knob to the

center position places the gearbox in neutral.

NOTICE

Change the speeds when the planer/mould-

er is running, but DO NOT attempt to change

speeds during any cutting operations or

damage to the gearbox will result.

Figure 11. Feed control knob positions.

0

11

22

0

11

22

22

FPM

11

FPM

Neutral

Speed

Indicator

Arrow