G0486/G0487 Wide Belt Sander -15-

Site Considerations

Floor Load

Refer to the Machine Data Sheet for the weight

and footprint specifications of your machine.

Some residential floors may require additional

reinforcement to support both the machine and

operator.

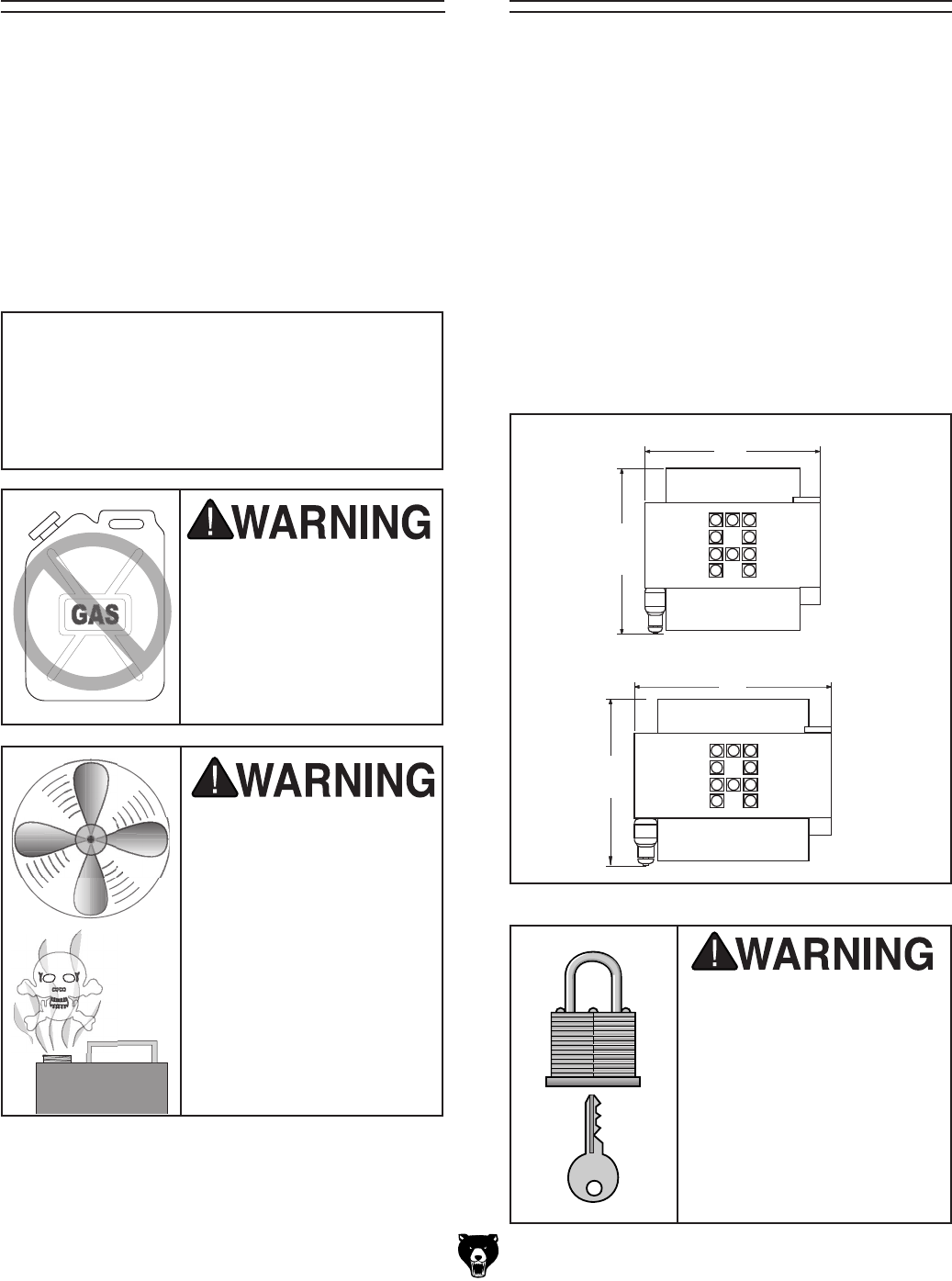

Working Clearance

Consider existing and anticipated needs, size of

material to be processed through each machine,

and space for auxiliary stands, work tables or

other machinery when establishing a location for

your new machine. See Figure

10 for the mini-

mum working clearances.

Unsupervised children and

visitors entering a shop

could suffer serious per

-

sonal injury. Ensure child

and visitor safety by keep

-

ing all entrances to the

shop locked at all times.

DO NOT allow unsuper

-

vised children or visitors

in the shop at any time.

Clean Up

Any unpainted surfaces are coated with a waxy

oil to protect them from corrosion during ship

-

ment. Remove this protective coating with a sol

-

vent cleaner or citrus-based degreaser such as

Grizzly’s G7895 Degreaser. To clean thoroughly,

some parts may need to be removed. For opti

-

mum performance from your machine, make

sure you clean all moving parts or sliding

contact surfaces that are coated. Avoid chlo

-

rine-based solvents as they will damage painted

surfaces should they come in contact.

Gasoline and petroleum

products have low flash

points and could explode

if used to clean machin

-

ery. DO NOT use gasoline

or petroleum products to

clean the machinery.

Lack of ventilation while

using solvents could

cause serious person

-

al health risks, fire, or

environmental hazards.

Always work in a well

ventilated area to pre

-

vent the accumulation

of dangerous fumes.

Supply the work area

with a constant source

of fresh air.

Figure 10. Minimum working clearances.

G0486

G0487

NOTICE

The steel sanding belt rollers have been

coated with an export grease to protect

them from rust. This grease should be

removed before installing the sanding belt.