G1182 6" Series Jointers -25-

Surface Planing Rabbet Cuts

The purpose of planing on a jointer is to produce

one flat surface. The theory behind this is that

once you have one flat surface on a board, it can

then more readily be milled to precise, final

dimensions on a thickness planer. It is nearly

impossible to surface plane both sides of a board

effectively because the two surfaced sides will

not be parallel to each other.

1. Inspect your lumber for soundness and grain

direction.

2. If the stock is cupped (warped), place the

concave side down and slowly feed it over

the cutterhead. See Figure 27.

3. Inspect your results. Most likely, many pass-

es will be necessary before your lumber has

a flat surface.

4. If the stock has large or loose knots, consid-

er finding another workpiece. Knots in a

workpiece can be dangerous to the operator,

as well as destructive to equipment.

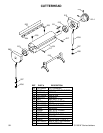

Figure 27. Correct method for surface planing.

A rabbet is a groove cut along the edge of a

board. It is usually made to accept another board

to form a strong, simple joint. Note: The maxi-

mum rabbet depth is

1

⁄2".

1. Unplug the jointer and remove the cutter-

head guard.

2. Loosen the fence and slide it to the rabbeting

edge. Set the fence to the desired width of

the rabbet and lock down. For small rabbets,

remove the fence sliding locking lever and

reinsert it in the rear fence hole on the fence

base.

3. Inspect stock for soundness and grain direc-

tion.

4. Place stock on the infeed table and rabbet

table with the edge to be rabbeted firmly

against the fence.

5. Slowly and evenly feed stock through the

cutterhead. Using the

1

⁄16" rule, it will take six

passes to achieve a common

3

⁄8" rabbet. See

Figure 28.

6. Replace the guard when finished with rab-

beting operations.

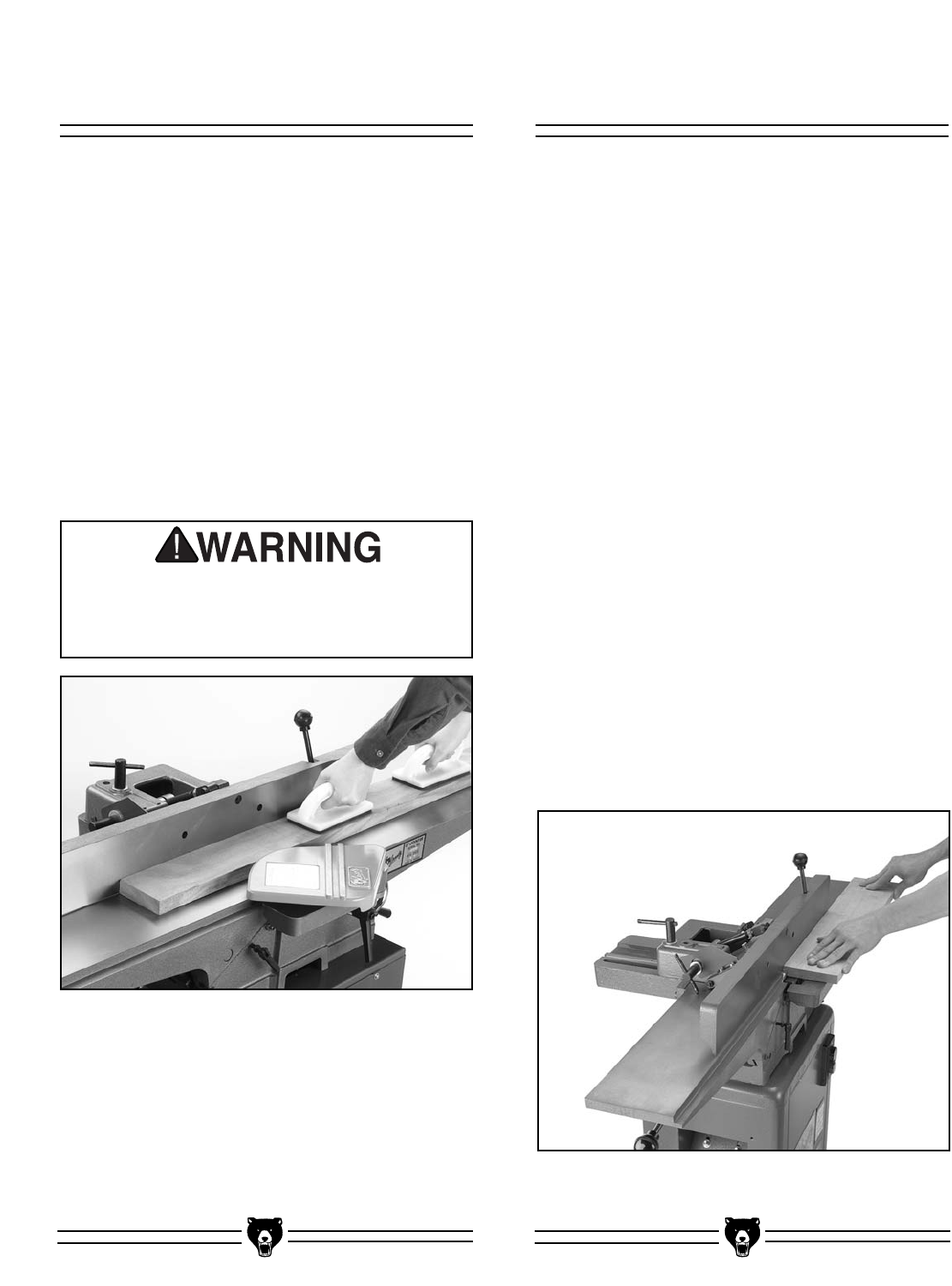

Figure 28. Correct operator position for rabbet

cutting.

Always use push paddles when planing the

surface of a board. Failure to comply may

result in serious personal injury.