-20- G7209/10 14'' Table Saw

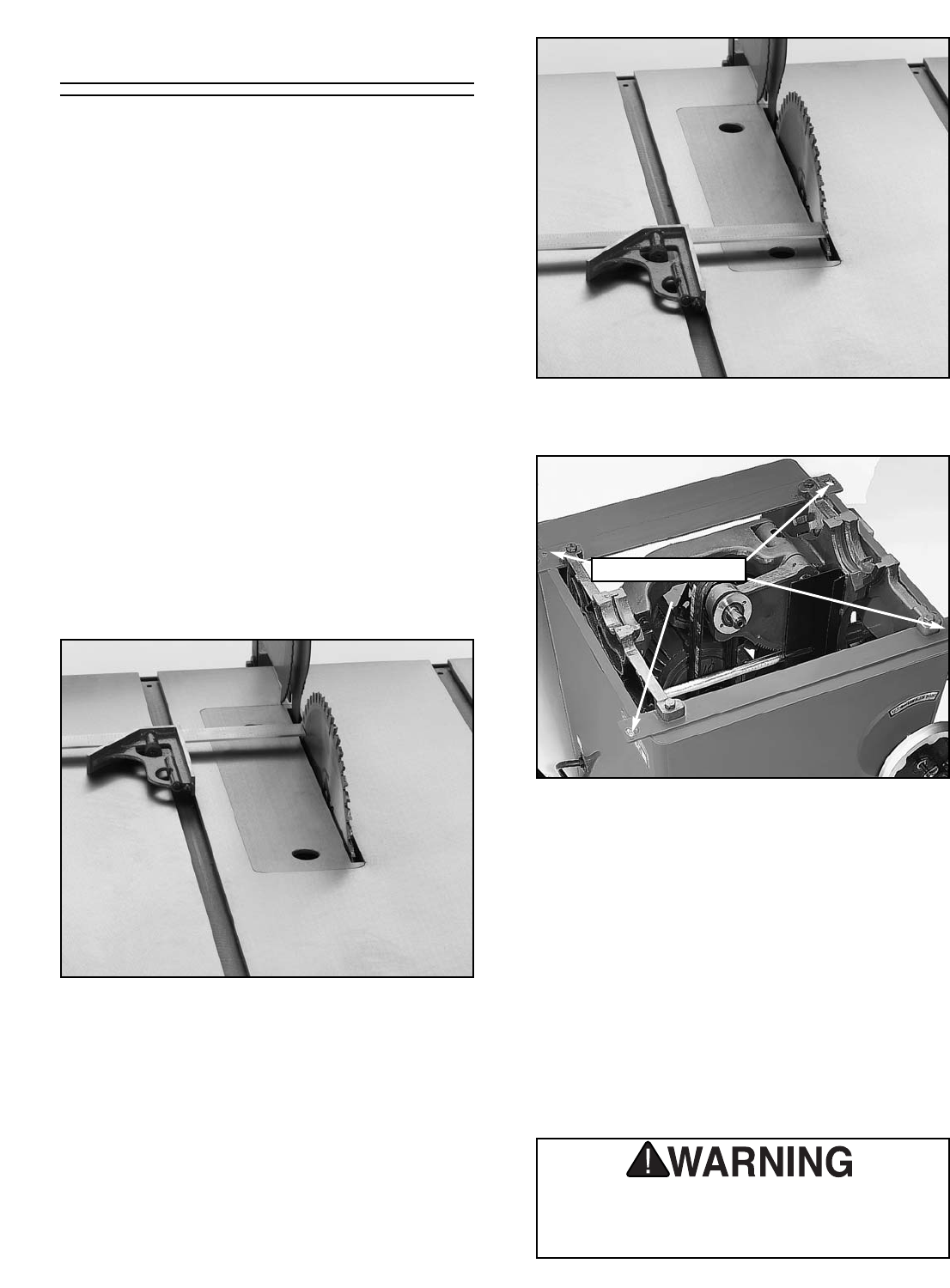

Figure 22. Adjusting blade to miter slot after

rotating blade 180° and sliding square down

miter slot.

Figure 23. Table mounting bolt holes.

Table Mount Holes

5. The difference between the two measure-

ments must be equal to or less than

1

⁄64".

6. If the difference is greater than

1

⁄64", loosen

the four (4) table mounting bolts as seen in

Figure 23 and adjust the table slightly.

Repeat Steps 1-5 until satisfactory. Do not

forget to tighten the table mounting bolts

when finished.

7. Now check to see if the blade remains paral-

lel to the miter slot when tilted to 45°.

8. Tilt the blade to 45° and repeat Steps 1-5. If

the blade is still parallel to the miter slot, con-

tinue on to the “Miter Gauge” instructions.

Otherwise, continue with the next step.

9. If the blade was parallel to the miter slot at

90° but not at 45°, the table will need to be

shimmed with metal shim stock. The shims

are placed under the table over each of the

four table mounting bolts as shown in Figure

23.

Miter Slot to Blade

Your table saw will give the best results if the

miter slot and rip fence are adjusted parallel to

the blade. If they are not exactly parallel, your

cuts and finished work will be lower in quality, but

more important, it increases the risk of kickback.

Take the time to adjust your table saw properly. A

few minutes now will be time well spent.

1. Disconnect the power cord from the out-

let. Use a piece of tape to mark the blade in

the gullet between two (2) teeth closest to

the table.

2. Use an adjustable square to measure the

distance from the mark on the blade to the

edge of the miter slot. See Figure 21.

3. Rotate the blade 180°.

4. Measure the distance from the mark on the

blade to the edge of the miter slot. See

Figure 22.

Figure 21. Adjusting blade to miter slot.

The saw blade is dangerously sharp. Use

extra care when handling the blade or work-

ing near it. Serious injury is possible.